A kind of anti-leakage grease sealing structure of fan turntable bearing

A technology of slewing bearing and sealing structure, applied in the direction of shaft and bearing, bearing components, mechanical equipment, etc., can solve the problems of insufficient pressure resistance limit of the sealing ring, leakage of grease at the sealing ring, poor stability and reliability, etc. The operation process is stable and reliable, the function is ensured, and the effect of eliminating the interference of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

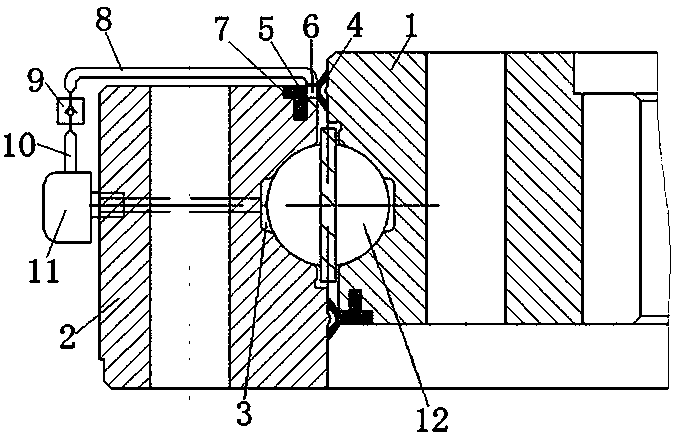

[0022] see figure 1 As shown, the present invention includes an inner ferrule 1, an outer ferrule 2 and an oil return system.

[0023] Wherein, the inner ferrule 1 and the outer ferrule 2 are radially fitted and assembled together. Specifically, a row of corresponding raceways 3 is provided between the outer peripheral surface of the inner ring 1 and the inner peripheral surface of the outer ring 2, and the raceways 3 are circumferentially formed between the inner ring 1 and the outer ring 2, and the raceways 3 is used to accommodate the rolling element 12; the inner ring 1 and the outer ring 2 are assembled together in a relative rotation manner through the rolling element 12 in the raceway 3. In the radial direction of the aforementioned outer ring 2, there are a plurality of grease discharge holes communicating with the raceway 3—that is, the main grease discharge holes.

[0024] The raceway 3 between the inner ring 1 and the outer ring 2 is injected with lubricating grea...

Embodiment 2

[0029] The invention includes an inner ring, an outer ring and an oil return system.

[0030] Wherein, the inner ferrule and the outer ferrule are radially fitted together. Specifically, a row of corresponding raceways is provided between the outer peripheral surface of the inner ring and the inner peripheral surface of the outer ring, and the raceways are circumferentially formed between the inner ring and the outer ring, and the raceways are used to accommodate rolling elements ; The inner ring and the outer ring are assembled together in a relatively rotating manner through the rolling elements in the raceway. In the radial direction of the aforementioned outer ring, there is a grease discharge hole communicated with the raceway—that is, the main grease discharge hole.

[0031] The raceway between the inner ring and the outer ring is injected with lubricating grease to ensure that the rolling elements can achieve good rolling operation in the raceway. There are sealing ri...

Embodiment 3

[0035] The invention includes an inner ring, an outer ring and an oil return system.

[0036] Wherein, the inner ferrule and the outer ferrule are radially fitted together. Specifically, two rows of corresponding raceways are provided between the outer peripheral surface of the inner ring and the inner peripheral surface of the outer ring, and the raceways are formed circumferentially between the inner ring and the outer ring, and the raceways are used to accommodate rolling body; the inner ring and the outer ring are assembled together in a relatively rotational manner through the rolling elements in the raceway. In the radial direction of the aforementioned inner ring, there are a plurality of grease discharge holes communicated with the raceway—that is, the main grease discharge hole.

[0037] The raceway between the inner ring and the outer ring is injected with lubricating grease to ensure that the rolling elements can achieve good rolling operation in the raceway. Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com