Device capable of compressing divergence angle of VCSEL laser

A technology of laser and divergence angle, applied in the direction of controlling laser output parameters, lasers, laser parts, etc. It can solve the problems of large light-emitting angle, no devices, and products that cannot work normally, so as to increase manufacturability and reduce installation. puzzle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

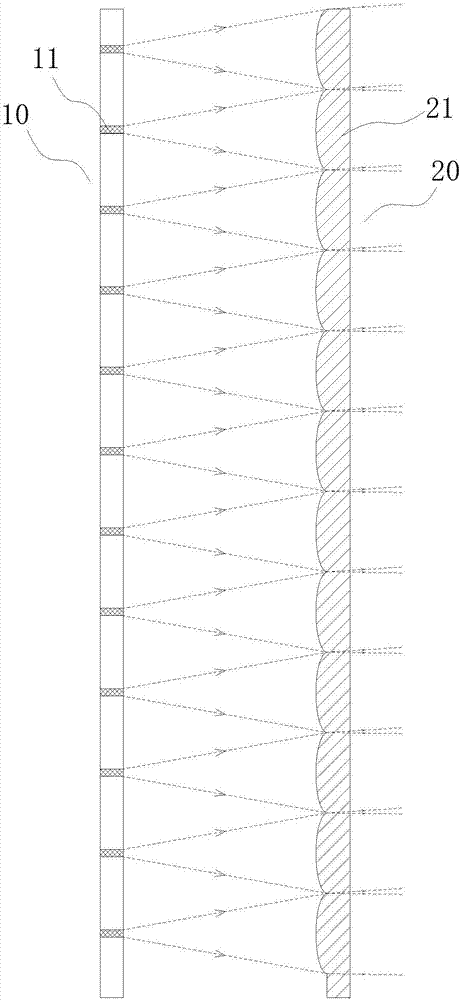

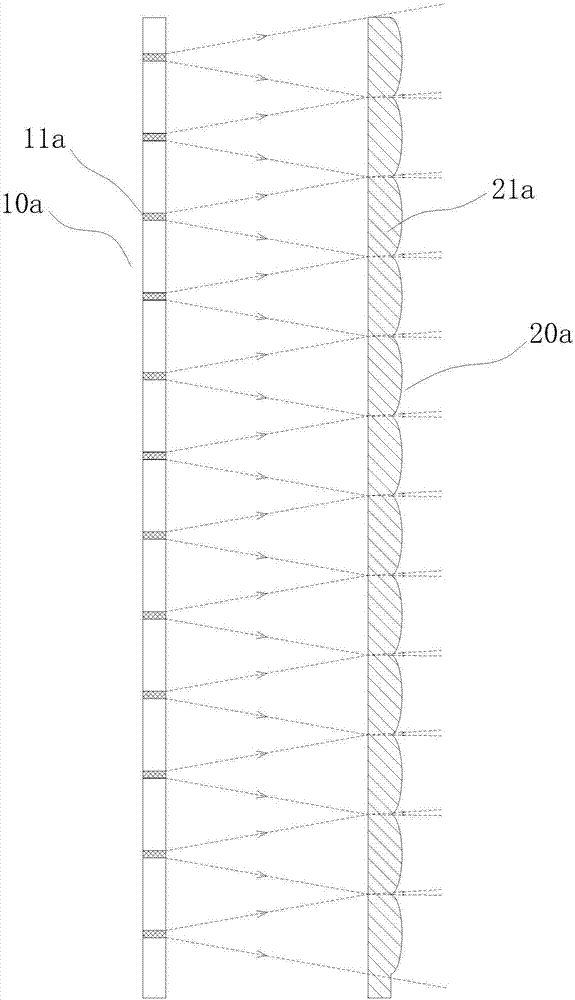

[0013] For a device capable of compressing the divergence angle of a VCSEL laser in this embodiment, please refer to the attached figure 1 , comprising a VCSEL laser 10 arranged at one end, the light-emitting surface of the VCSEL laser 10 is provided with a microlens array 20 at intervals, each microlens of the microlens array 20 is a plano-convex lens 21, and the convex surface of the plano-convex lens 21 Close to and towards the light-emitting surface of the VCSEL laser 10 , the plane of the plano-convex lens 21 is away from the VCSEL laser 10 .

[0014] Each microlens of the microlens array 10 of the device is a plano-convex lens 21, wherein the convex surface of the plano-convex lens 21 is close to and towards the light-emitting surface of the VCSEL laser 10, and the plane of the plano-convex lens 21 is away from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com