Cold and hot water tank assembly of water boiler

A technology for water boilers and hot water tanks, applied in applications, coatings, kitchen utensils, etc., can solve the problems of short service life of the insulation layer and achieve low cost, improved insulation performance, reasonable composition selection and composition design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

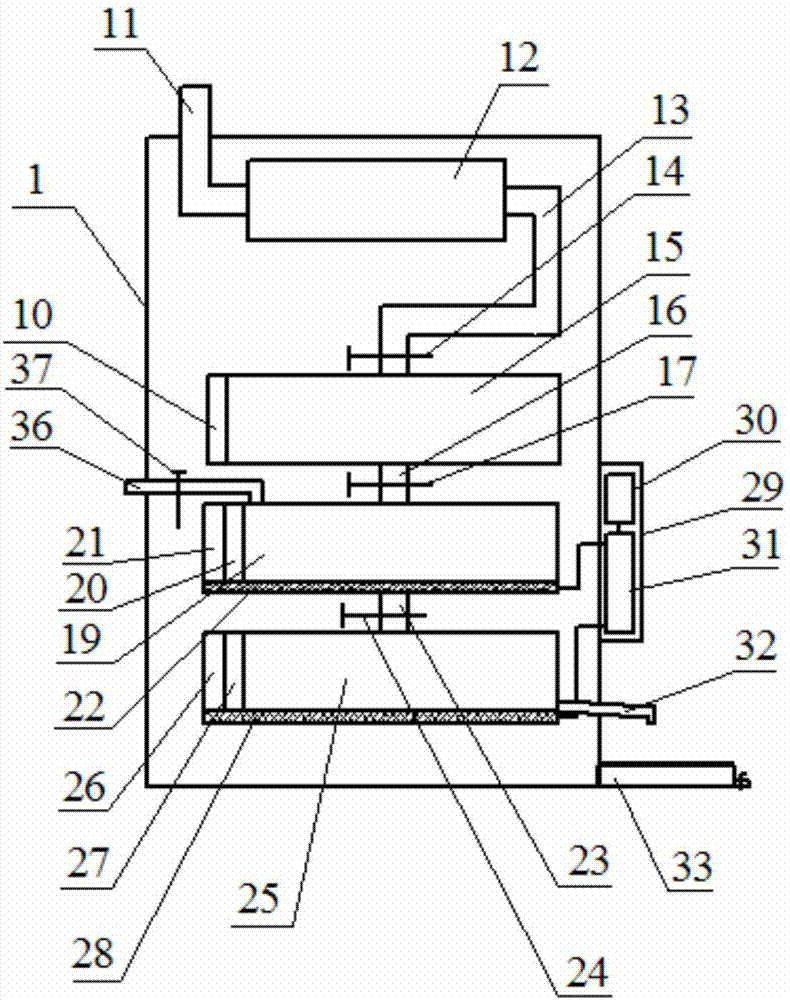

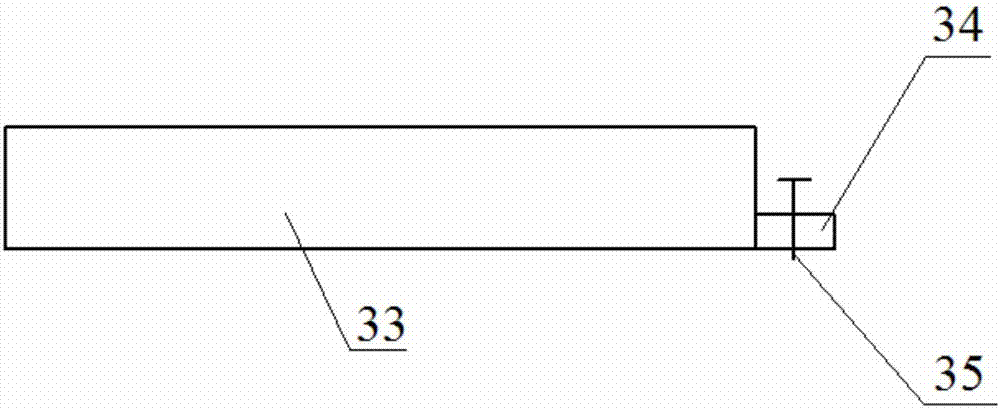

[0031] like Figure 1 to Figure 2 As shown, the present invention provides a water boiler, comprising a box body 1, a water inlet 11 located at the top of the box body 1, a filter element 12 communicated with the water inlet 11, a first water pipe 13 communicated with the filter element 12, and a first water pipe connected to the first water pipe. The cold water tank 15 communicated with 13, the second water pipe 16 communicated with the cold water tank 15, the hot water tank 19 communicated with the second water pipe 16, the third water pipe 23 communicated with the hot water tank 19, the storage tank communicated with the third water pipe 23 The water tank 25 and the water outlet 32 communicated with the water storage tank 25 .

[0032] Specifically, the filter element 12 may be a granular activated carbon filter element, a ceramic filter element, an ultrafiltration membrane filter element or a reverse osmosis membrane filter element, and is used for filtering the water en...

Embodiment 2

[0040] A manufacturing process of a hot and cold water tank assembly of a water boiler, the steps are as follows:

[0041] ①. Composition of hot and cold water tank components and component molding

[0042] The hot and cold water tank assembly consists of a filter element, a cold water tank, a hot water tank, a water storage tank and various connecting pipelines. The bottom of the hot water tank is equipped with a first heater, and the bottom of the water storage tank is equipped with a second heater; the filter element is a granular activated carbon filter element, Ceramic filter element, ultrafiltration membrane filter element or reverse osmosis membrane filter element;

[0043] The cold water tank, hot water tank, and water storage tank are all composed of an outer shell and an inner tank. The outer shell is made of PP, and the inner tank is made of PTFE;

[0044] The filter element adopts commercially available granular activated carbon filter element, ceramic filter elemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com