Precise machining machine tool for small-caliber rotating shaft symmetrical optical curved elements

A technology of precision machining and rotating shafts, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., and can solve the problems of low processing accuracy and processing efficiency, limited processing materials, and large cumulative errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

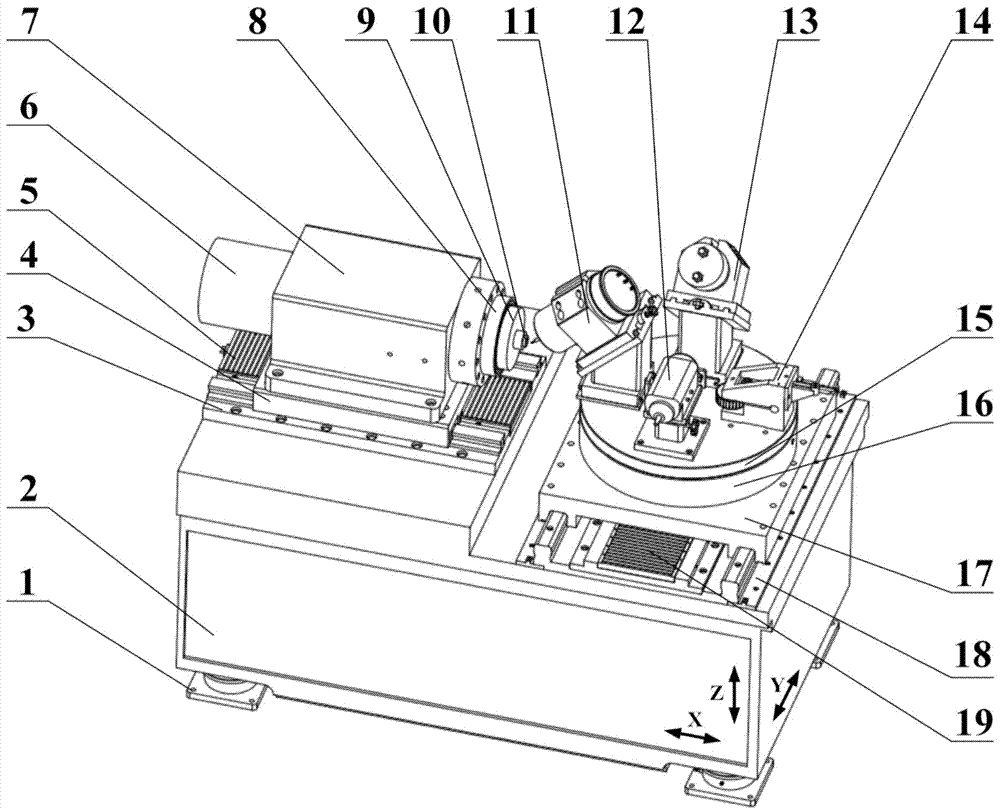

[0029] See attached figure 1 , the precision machining machine tool for small-diameter rotating axisymmetric optical curved surface elements of the present invention, the bed 2 is made of natural granite, and an air cushion type shock absorber 1 is respectively arranged at the four corners of the bottom surface of the lower end, which can create a stable processing environment for the machine tool.

[0030] See attached figure 1 A first guide rail 3 with a first linear motor 5 is installed on the left side of the upper surface of the bed 2, and a first slide table 4 is installed on the first guide rail 3. Driven by the electromagnetic thrust of the first linear motor 5 , the first sliding table 4 can freely reciprocate and translate along the X direction of the bed 2 on the first guide rail 3 . The first slide table 4 is provided with a first bracket 7 which can clamp the workpiece spindle 6 for loading and unloading. The right end of the workpiece spindle 6 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com