Ship propelled through front resistance elimination and rear pressure increase

A technology of ships and propulsion systems, which is applied in the direction of ship propulsion, propulsion components, hulls, etc., and can solve the problems of large hull shape resistance and wave-making resistance, drainage resistance at the front of the hull, and large radius of turning trajectory, etc., to achieve reduction Effects of wave resistance, reduced shape resistance, and flexible steering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with examples, but the present invention is not limited to these examples.

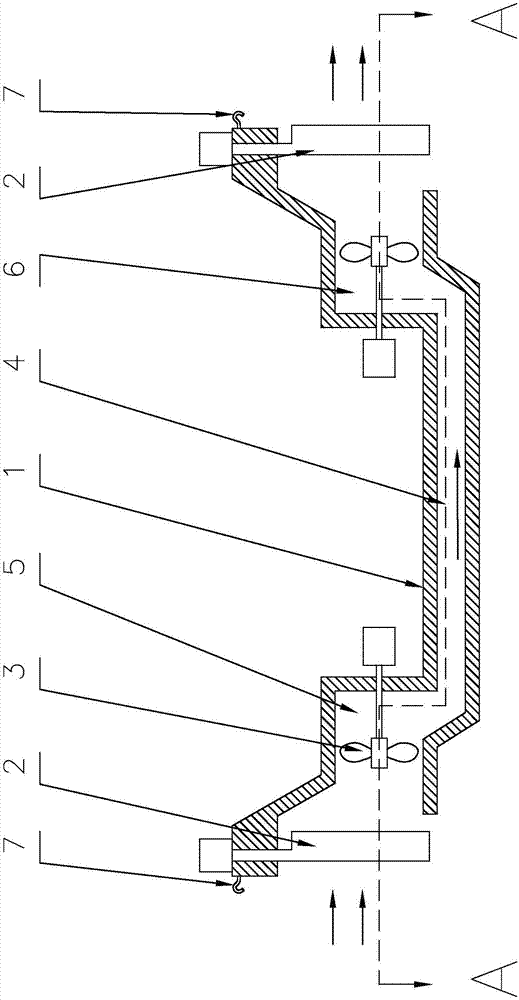

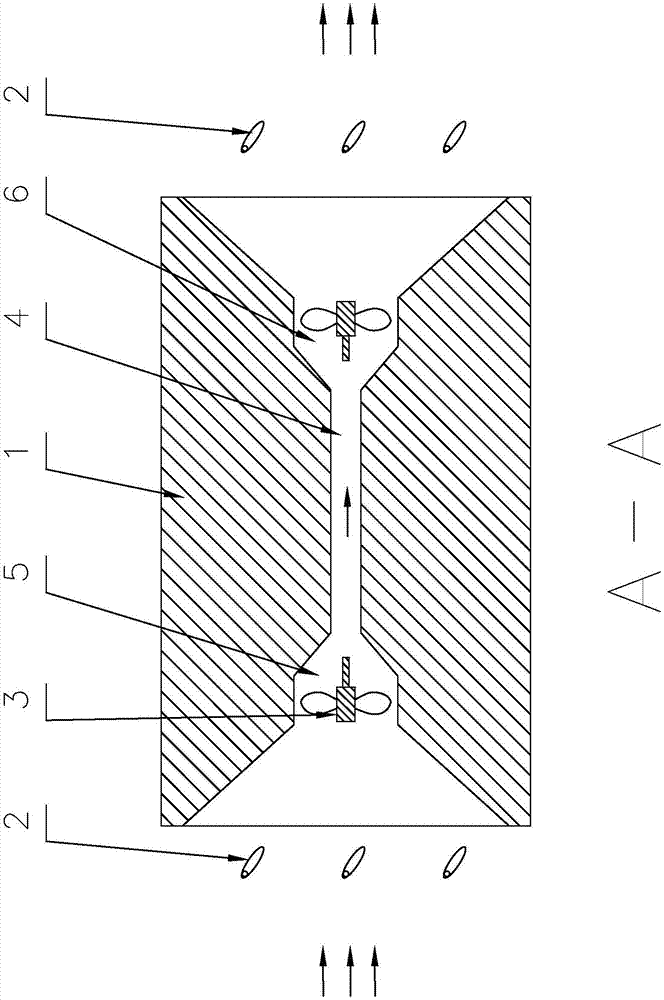

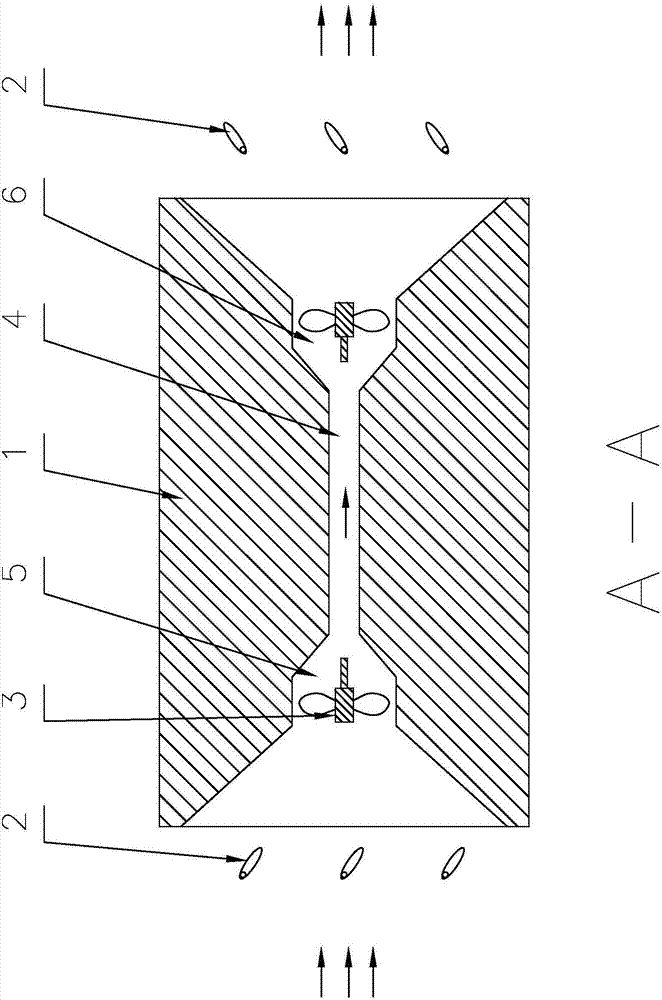

[0028] The present invention eliminates the front resistance and increases the rear pressure to propel the ship, including the hull 1, the rudder blade 2, and the propeller 3. Compared with the ordinary ship, the present invention eliminates the front resistance and increases the rear pressure to propel the ship below the hull 1. There is a propulsion system, and the propulsion system includes a water flow channel 4 connecting the front and rear ends of the hull 1 and allowing water to pass through the bottom of the hull 1. The propulsion system also includes a water inlet chamber 5 and a ship The water outlet bin 6 is provided at the rear end of the body 1, and the two ends of the water flow channel 4 are respectively connected to the water inlet bin 5 and the water outlet bin 6, and the water inlet bin 5 and the water outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com