Dry material bulk machine

A bulk machine and dry material technology, applied in the direction of conveyor, loading/unloading, transportation and packaging, etc., can solve problems such as poor discharge, low work efficiency, overflow, etc., to avoid misjudgment and misreaction, The effect of improving work efficiency and safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

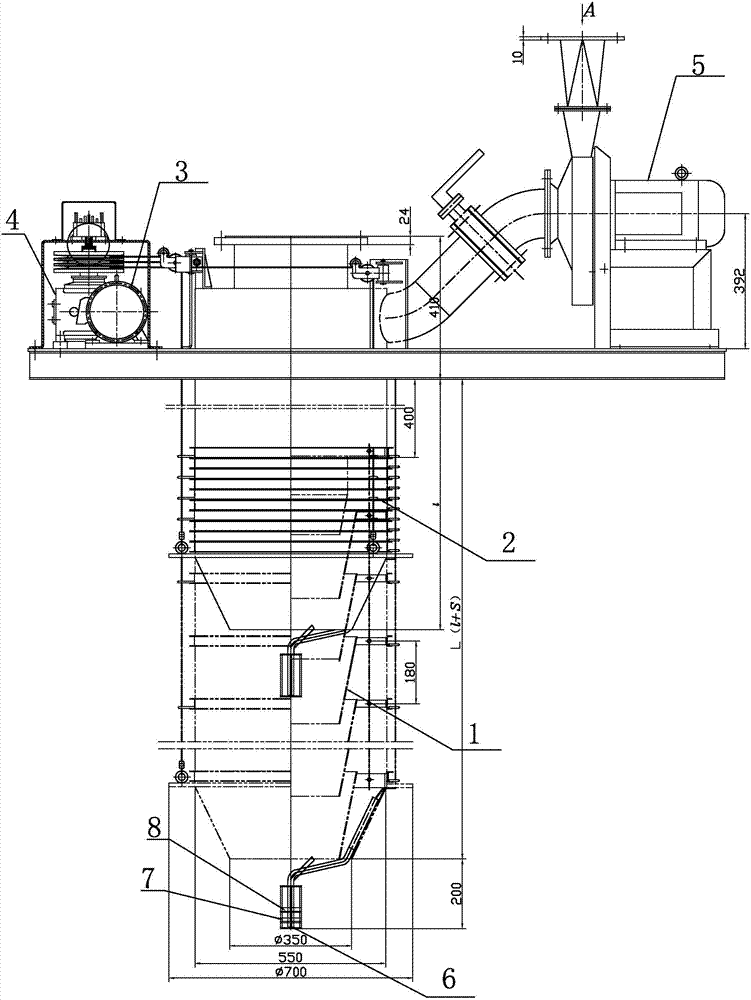

[0017] Such as figure 1 , a dry material bulk machine in this embodiment includes a telescopic device, a hoisting device 3, a control system 4 and a dust removal system 5, and the telescopic device includes a bulk head 1, an expansion joint 2, and a wire rope 6, and is characterized in that The bulk head 1 is equipped with a negative pressure detection device 8 and a light projection module 7 , and both the negative pressure detection device 8 and the light projection module 7 can feed back data to the control system 4 . , the control system 4 controls the loading and stopping state according to the feedback data. The light projection module 7 includes a light excitation device and a light receiving device. The light excitation device emits light in two directions, one is a projection light parallel to the central axis of the retractable device, and the other is perpendicular to the central axis toward the optical receiving device. The orientation of the device. The expansio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com