Surface treatment method of glass micro-beads for light reflection and application

A glass microbead, surface treatment technology, applied in optics, optical components, reflective/signal coatings, etc., can solve problems such as easy generation of static electricity, and achieve good antistatic and fluidity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

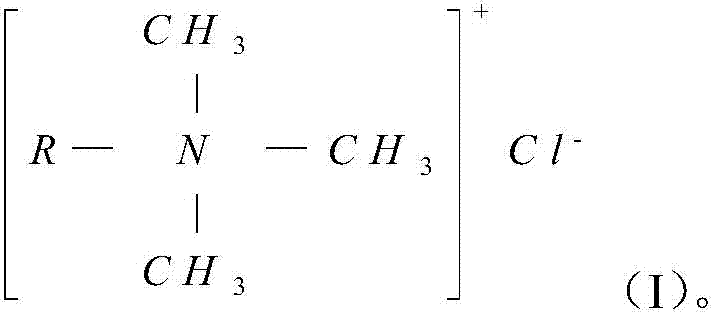

Method used

Image

Examples

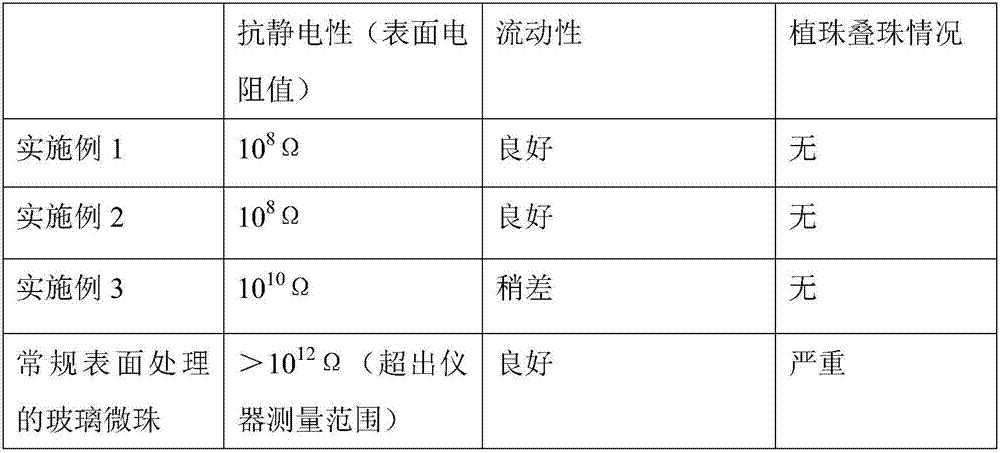

Embodiment 1

[0018] Mix 100 parts of octadecyltrimethylammonium chloride, 100 parts of fumed silicon dioxide, 200 parts of deionized water, and 100 parts of isopropanol and stir them evenly with an electric mixer to make a treatment solution. The temperature is 100°C, pour the treatment solution into 50,000 parts of glass beads in a high-speed mixer, stir and mix evenly, the stirring speed is 1000rps, and the stirring time is 5min, fully mix until uniform, and then bake in an oven at a temperature of 200°C , the time is 90 minutes, and after cooling, it becomes a kind of reflective glass beads 1 .

Embodiment 2

[0020] Mix 100 parts of dodecyltrimethylammonium chloride, 50 parts of fumed silica, 100 parts of deionized water, and 50 parts of isopropanol and stir them evenly with an electric mixer to make a treatment solution. The temperature is 60°C, pour the treatment solution into 30,000 parts of glass beads in a high-speed mixer, stir and mix evenly, the stirring speed is 800rps, and the stirring time is 3min, fully mixed until uniform, and then baked in an oven at a temperature of 150°C , the time is 50 minutes, and after cooling, it becomes a kind of reflective glass beads 2 .

Embodiment 3

[0022] Mix 100 parts of N, N, N-trimethyl-1-tetradecyl ammonium bromide, 1 part of fumed silica, and 1 part of deionized water, mix them with an electric mixer to make a treatment solution, and treat in a water bath The temperature of the treatment liquid is 25°C. Pour the treatment liquid into 10,000 parts of glass beads in a high-speed mixer, stir and mix evenly, the stirring speed is 600rps, and the stirring time is 1min. Fully mix until uniform, and then bake in an oven. The temperature is 50° C., and the time is 10 minutes. After cooling, a kind of reflective glass beads 3 are obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com