Taro leaf dye extracting method, dyeing method and application

An extraction method and taro leaf technology are applied in the directions of dyeing, azo dyes, organic dyes, etc., which can solve the problems of difficulty in collecting raw materials, waste of resources, low output, etc., and achieve the improvement of dyeing depth and color fastness. The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

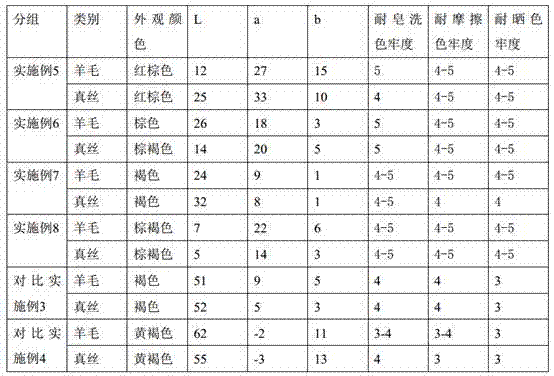

Examples

Embodiment 1

[0026] A kind of extracting method of taro leaf dye, comprises the following steps:

[0027] Step 1: After picking fresh taro leaves of mature taro and washing away other impurities such as sediment, evenly spray the soda water solution with a Ph of 10 on the taro leaves, and expose to the sun for browning at a temperature of 30°C and a relative humidity of 70°C. %, after 8 hours, the detected browning area has reached 90%, and browned taro leaves are obtained;

[0028] Step 2: Take the browned taro leaves in step 1 and soak them in 3% hydrogen peroxide for 15 minutes, then filter, dry or air-dry the taro leaves, and add them to the dried browned taro leaves 8 times after powdering with a powder machine In an ethanol solution with a mass fraction of 2% NaOH and a volume fraction of 30%, ultrasonic extraction was carried out at a temperature of 90°C for 180 min, and the filtrate was obtained by filtration. Dry in a dryer at 50°C to obtain brown dye powder.

Embodiment 2

[0030] A kind of extracting method of taro leaf dye, comprises the following steps:

[0031] Step 1: After picking fresh taro leaves of mature taro and washing away other impurities such as sediment, evenly spray the soda water solution with a Ph of 11 on the taro leaves, and expose to the sun for browning, the temperature is 32°C, and the relative air humidity is 60°C %, after 10 hours, the detected browning area has reached 93%, and browned taro leaves are obtained;

[0032] Step 2: Take the browned taro leaves in step 1 and soak them in 3% hydrogen peroxide for 20 minutes, then filter, dry the taro leaves, beat them with a powder machine, and add them to the dried browned taro leaves containing 5 times the weight of the dried taro leaves. In an ethanol solution with a mass fraction of 2% and a volume fraction of 25%, ultrasonic extraction was carried out at 60°C for 350 minutes, and the filtrate was obtained by filtration. After standing for 10 hours, the filtrate was centr...

Embodiment 3

[0034] A kind of extracting method of taro leaf dye, comprises the following steps:

[0035] Step 1: After picking fresh taro leaves of mature taro and washing away other impurities such as sediment, evenly spray the soda water solution with a Ph of 9 on the taro leaves, and expose to the sun for browning, the temperature is 25 ° C, and the relative air humidity is 80 %, after 6 hours, the detected browning area has reached 85%, and browned taro leaves are obtained;

[0036] Step 2: Take the browned taro leaves in step 1 and soak them in 3% hydrogen peroxide for 15 minutes, then filter, dry the taro leaves, beat them with a powder machine, and add 8 times the weight of the dried browned taro leaves. In an ethanol solution with a mass fraction of 2% and a volume fraction of 45%, ultrasonic extraction was carried out at a temperature of 70°C for 300 min, and the filtrate was obtained by filtration. ℃ drying to obtain brown dye powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com