Water-cooling water sealing type biomass gasifier and gasifying method

A gasifier and water-cooling technology, applied in the field of gasifiers, can solve the problems of incomplete separation of gas, oil and slag, only one explosion-proof water seal device, complicated working process of the gasifier, etc., and achieves good cooling effect. , Simple structure, good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

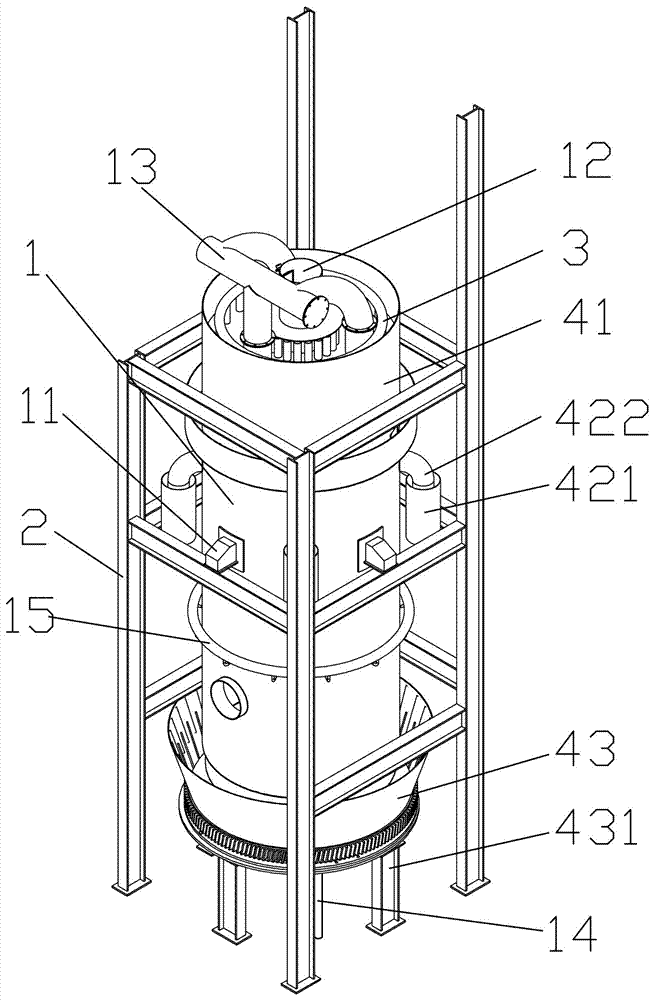

[0028] Embodiment one: as attached figure 1 Shown is only one of the embodiments of the present invention, a water-cooled water-sealed biomass gasification furnace, including a furnace body 1, the outside of the furnace body 1 is provided with a bracket 2 for fixing the furnace body 1, the The furnace body 1 is connected to the bracket 2 through the fixed feet 11, the upper part of the furnace body 1 is provided with a feed port 12 and the gas outlet 13, and the lower part of the furnace body 1 is provided with a primary blast port 14 and a secondary blast port 15 , the furnace body 1 is also provided with a water cooling device 3 and an explosion-proof device 4, the main body of the water cooling device 3 is a water-cooled tube 31, and the explosion-proof device 4 includes an upper explosion-proof device 41, a middle explosion-proof device 42, and a lower explosion-proof device 43 , the upper explosion-proof device 41 is arranged on the upper part of the furnace body 1 , and ...

Embodiment 2

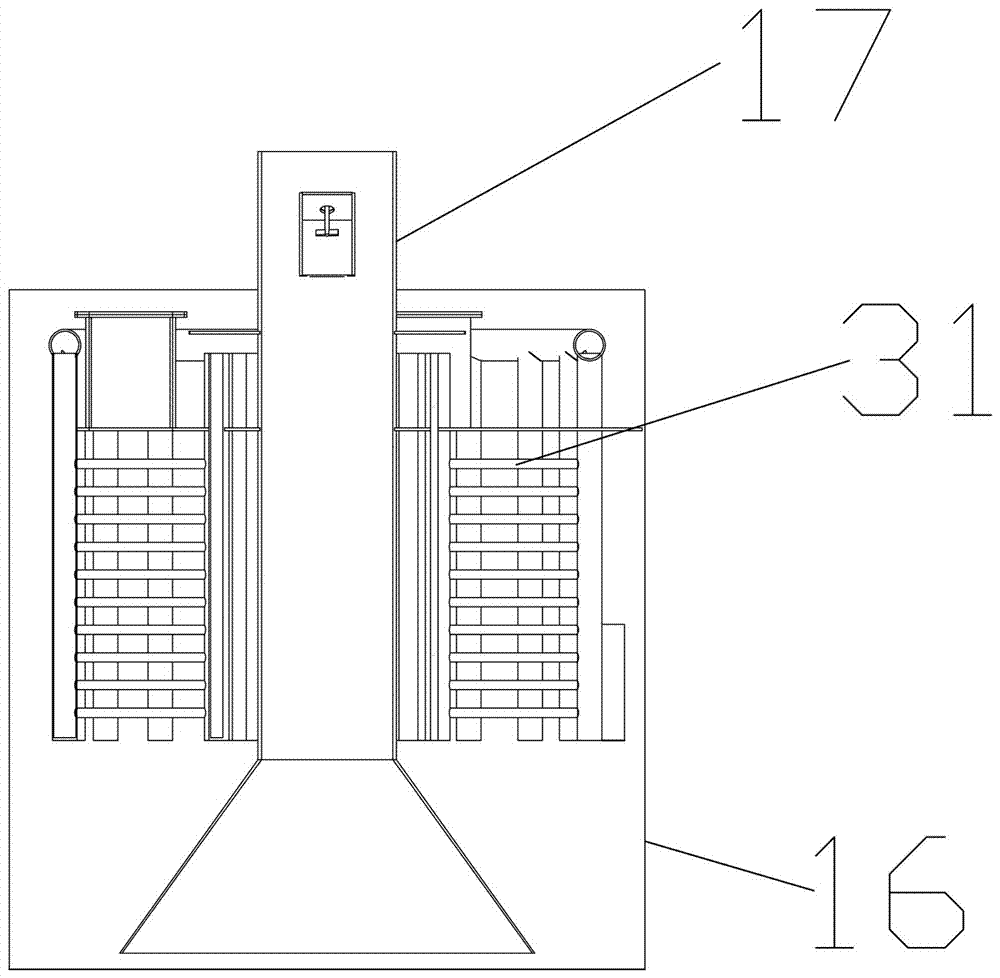

[0030] Embodiment two: if figure 2 As shown, the improvement on the water cooling device 3, the furnace body 1 includes an outer furnace body 16 and an inner furnace body 17, the water cooling device 3 is arranged in the space between the outer furnace body 16 and the inner furnace body 17, and the water cooling tubes 31 are stainless steel Water-cooled tubes.

[0031] The water-cooling tube array 31 includes a water inlet pipe, a cooling pipe and a water outlet pipe. The water inlet pipe includes a water inlet elbow and a water inlet straight pipe. The water outlet pipe includes a water outlet elbow and a water outlet straight pipe. The water outlet straight pipe passes through at least one cooling pipe and Water inlet straight pipe connection. Cooling water flows into each water inlet straight pipe from the water inlet elbow, and then flows into the cooling pipe to cool the high-temperature gas, and the obtained high temperature water flows into the water outlet elbow from...

Embodiment 3

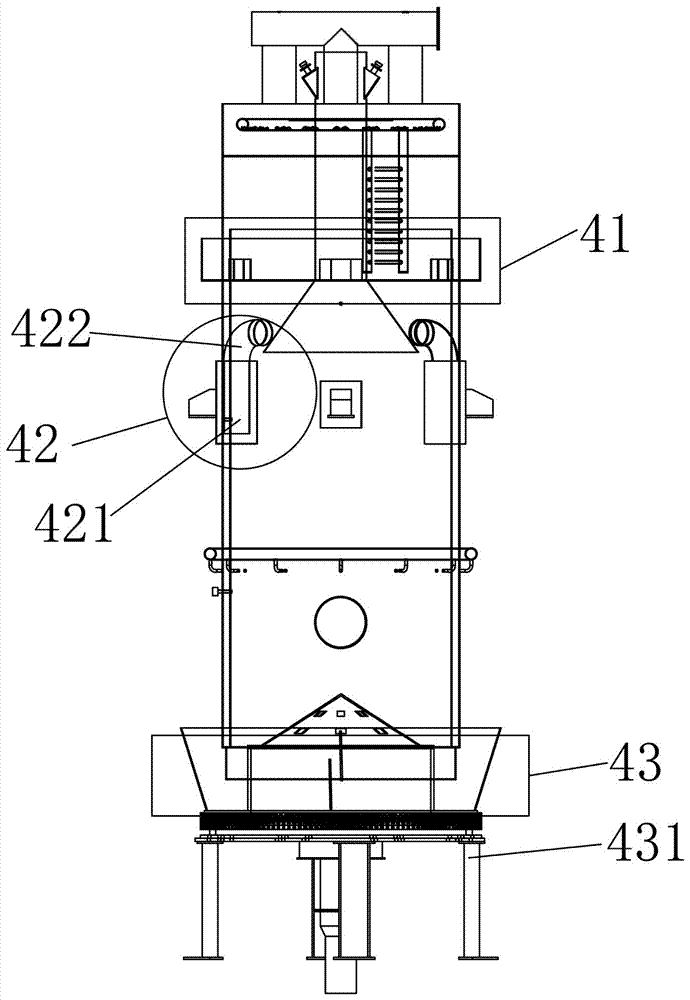

[0032] Embodiment three: as image 3 As shown, the improvement of 4 on the explosion-proof device, the explosion-proof device 4 is a water-sealed explosion-proof device, the explosion-proof device 4 includes an upper explosion-proof device 41, a middle explosion-proof device 42, and a lower explosion-proof device 43, and the upper explosion-proof device 41 is arranged on the The upper part of the furnace body 1, the lower explosion-proof device 43 is arranged on the lower part of the furnace body 1; the lower explosion-proof device 43 is provided with a fixing frame 431 for fixing the lower explosion-proof device 43, and the lower explosion-proof device 43 is provided with a screw out The slag container, the explosion-proof device 42 includes an explosion-proof barrel 421 and an explosion-proof elbow 422 .

[0033] The upper explosion-proof device 41 is located in a place where the combustible gas is dense, where the combustible gas is in a water-sealed state, and the combusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com