Compressor protection device and compressor system

A compressor system and protection device technology, which is applied in the field of compressors, can solve problems such as larger vibration amplitude and tilt angle of the compressor, increased transportation costs, and compressor bumping into surrounding parts, etc., so as to reduce the vibration or tilt The effect of reducing the range of transportation costs and avoiding excessive deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

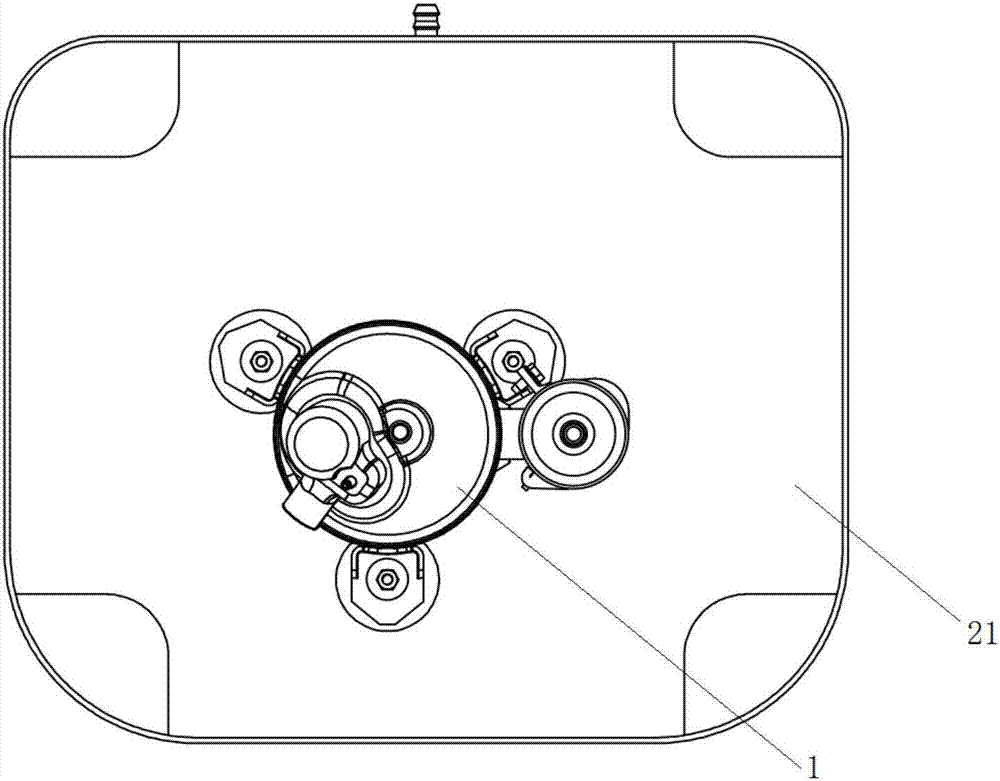

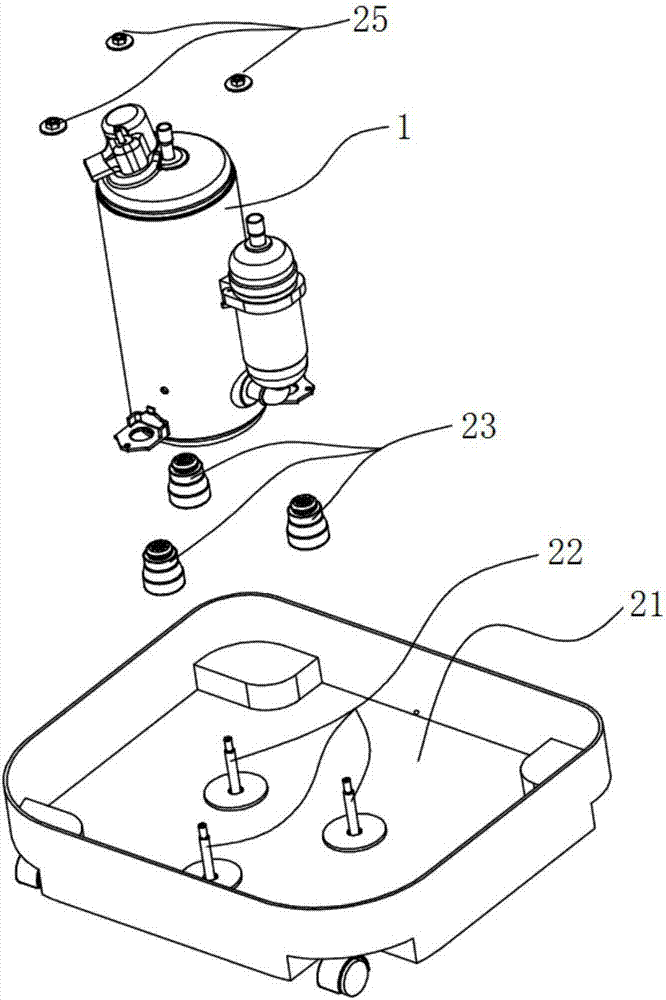

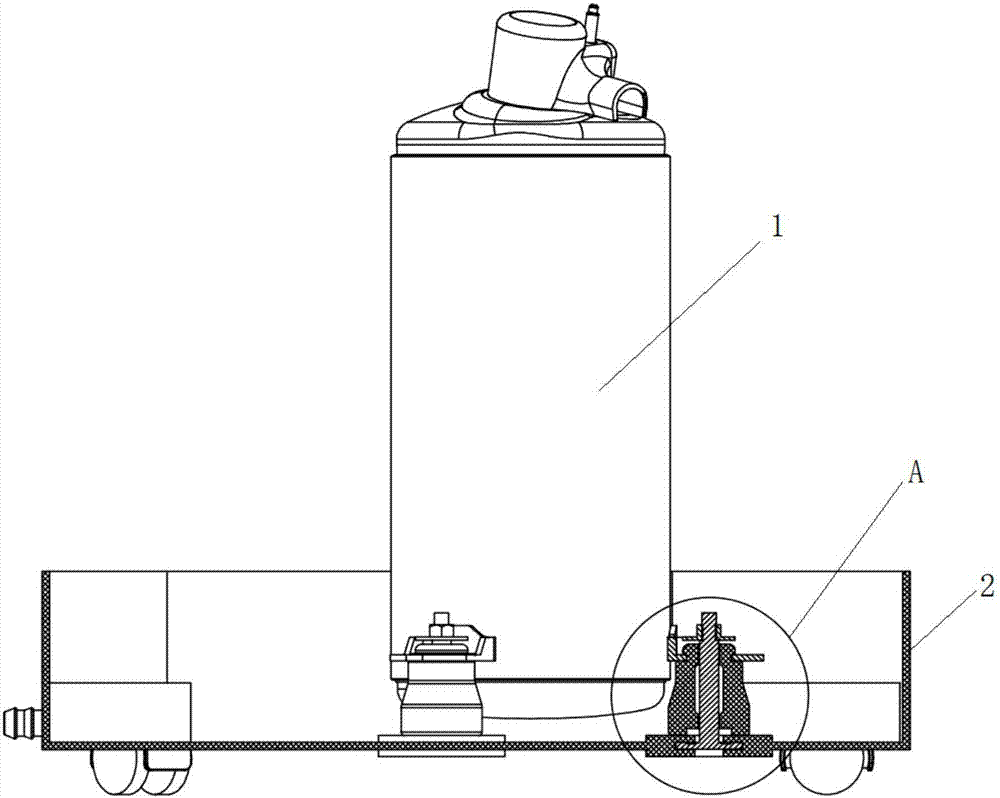

[0049] This embodiment provides a compressor protection device, such as Figure 5 to Figure 11 As shown, the protection device for the compressor in this embodiment includes a chassis 31 , a rubber pad 33 and a protection structure 34 . Wherein, the rubber pad 33 is limited on the chassis 31 by a limit structure (wherein, the specific design of the limit structure is detailed in the content described in Embodiment 4), and the rubber pad 33 is used to connect the fixing parts on the compressor 1 11. Wherein, the protective structure 34 is arranged on the chassis 31 and is used to limit the displacement of the fixing member 11 within a set range.

[0050]Because the rubber pad 33 is a relatively soft rubber material, when the compressor 1 shakes, under the action of the fixing member 11, the rubber pad 33 will be deformed (especially, the height of the rubber pad 33 will be reduced); When vibrating or receiving impacts such as falling, the rubber pad 33 will be excessively def...

Embodiment 2

[0053] Preferably, this embodiment provides a compressor protection device, compared with the previous embodiment, such as Figure 10 and Figure 11 As shown, the protective structure 34 in the present embodiment can limit the displacement of the fixing member 11 to the direction of the chassis 31 (that is, as Figure 11 As shown, the displacement of the fixing member 11 moving downward).

[0054] The compressor protective device provided in this embodiment is provided with a protective structure 34 on the chassis 31 to limit the displacement of the fixing member 11 moving downward, thereby preventing the rubber pad 33 from being excessively compressed, so as to reduce the vibration or tilt of the compressor 1. range, and reduce the volume of electrical equipment, and reduce the transportation cost of electrical equipment.

Embodiment 3

[0056] Preferably, this embodiment provides a compressor protection device, compared with Embodiment 2, such as Figure 5 and Figure 6 , Figure 9 to Figure 11 As shown, the present embodiment further designs the protective structure 34 as follows:

[0057] When the fixing part 11 on the compressor 1 is connected to the rubber pad 33 , the protective structure 34 is located below the fixing part 11 , and the minimum distance d between the protective structure 34 and the fixing part 11 is a first set distance. Preferably, the first set distance is 0.2-5mm. Here, the protection device for the compressor provided in this embodiment directly locates the protection structure 34 under the fixing part 11 of the compressor 1 to limit the displacement of the fixing part 11 moving downward, thereby preventing the rubber pad 33 from being excessively compressed. Reduce the shaking or tilting of compressor 1.

[0058] Preferably, the protective structure 34 in this embodiment is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com