Three plunger reciprocating pump

A technology of reciprocating pumps and pump heads, which is applied in the direction of pump components, variable displacement pump components, and components of pumping devices for elastic fluids, etc. It can solve problems such as poor processing technology and stress concentration in flow channels, and achieve increased strength , Thickness reduction, and the effect of simplifying the processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

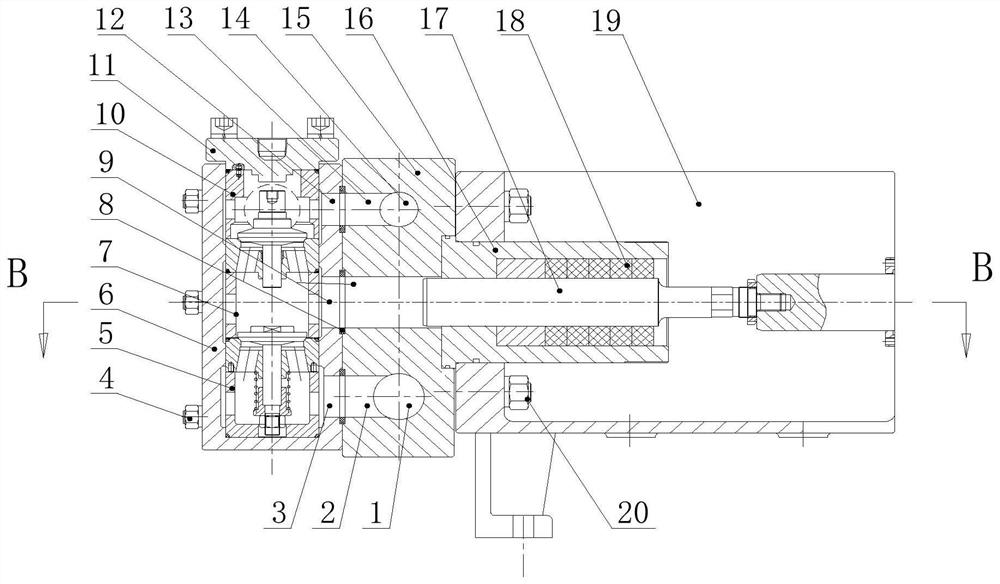

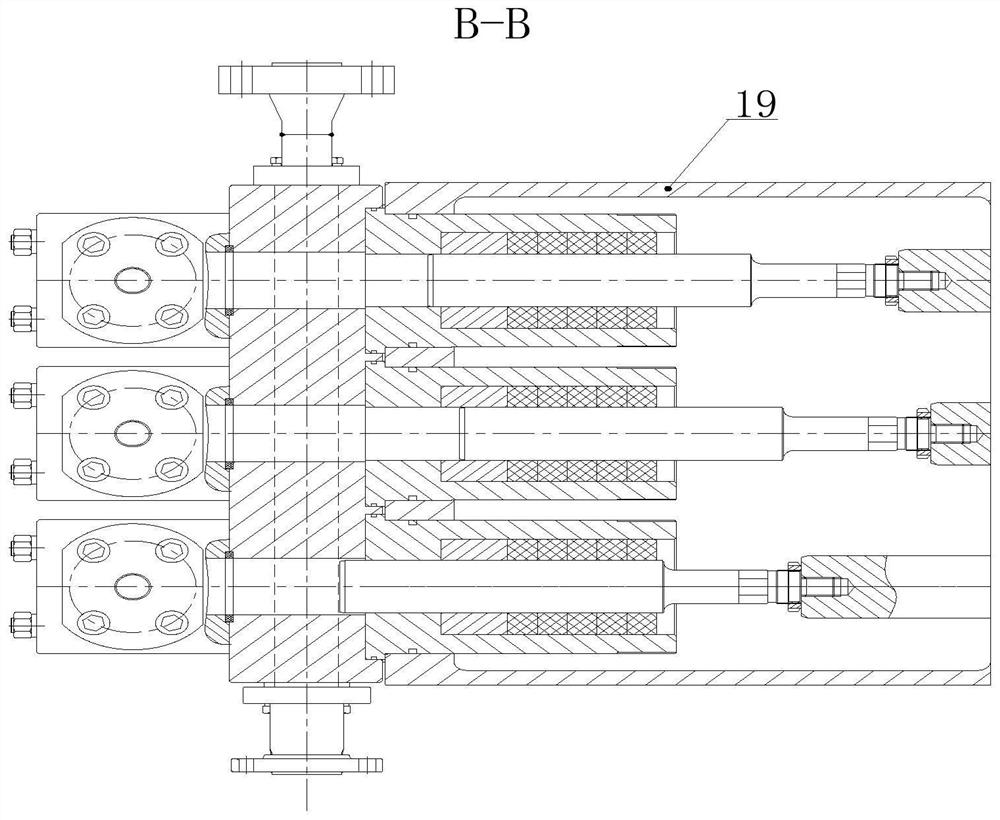

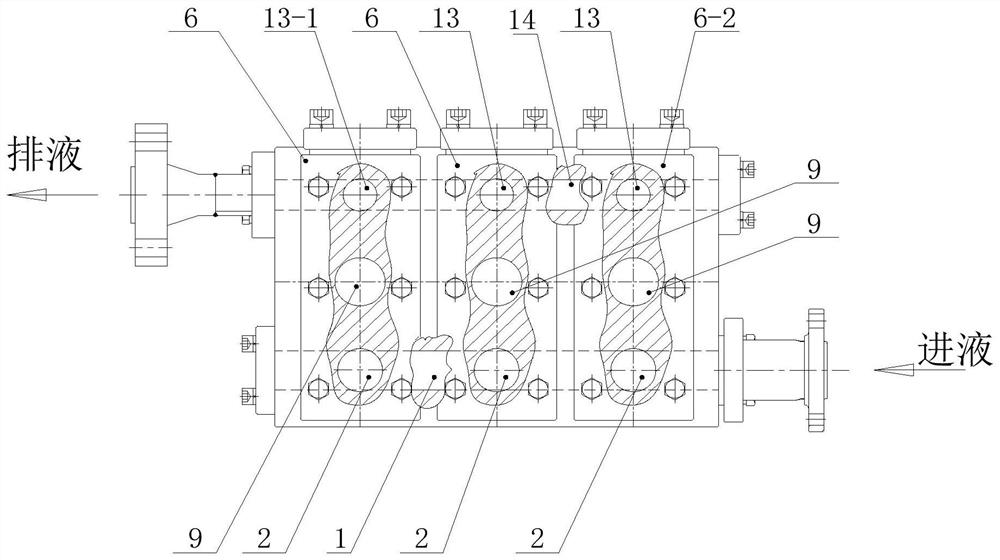

[0026] The above and other technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

[0027] The invention provides a three-plunger reciprocating pump. The reciprocating through hole of the plunger of the traditional three-plunger reciprocating pump penetrates the cavity of the one-way valve group, and the liquid inlet channel and the liquid discharge channel also run through the cavity of the valve group, forming a cross fluid channel. very bad. Especially at the intersection of each flow channel, it is easy to cause stress concentration, especially in the middle and high pressure conditions, it is easy to cause cracking of the pump head and cause operation accidents. The invention simplifies the inner channel of the reciprocating pump by arranging and installing the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com