Longitudinal 5-speed automatic gearbox for commercial vehicle

A technology for automatic transmission and commercial vehicles, applied in the direction of vehicle transmission, transmission components, transmission devices, etc., can solve the problems of high cost, complex process or mold, etc., to improve torque density, simplify process, and good adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

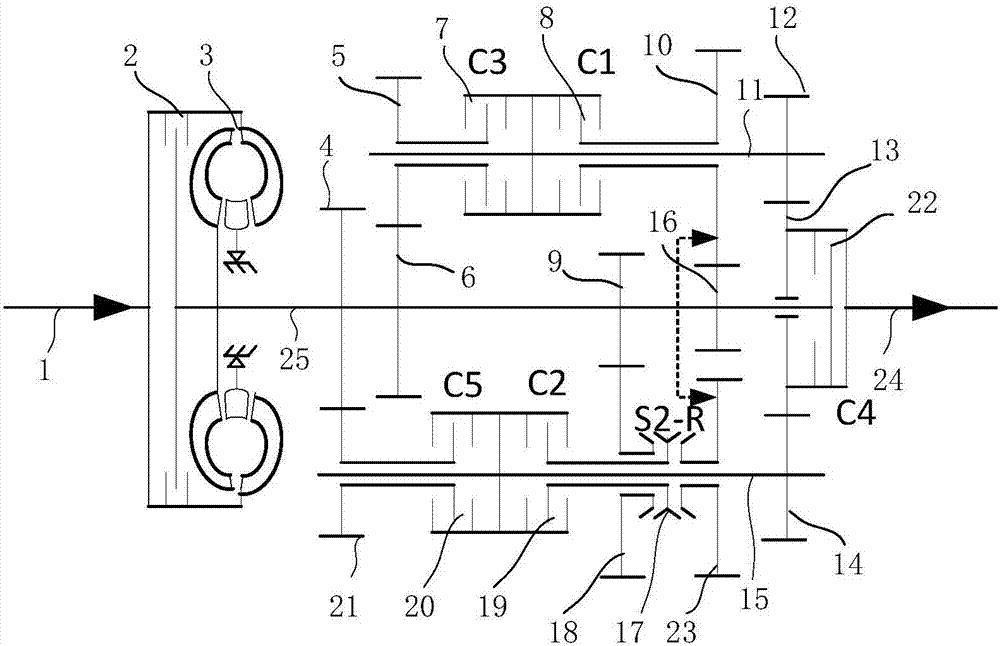

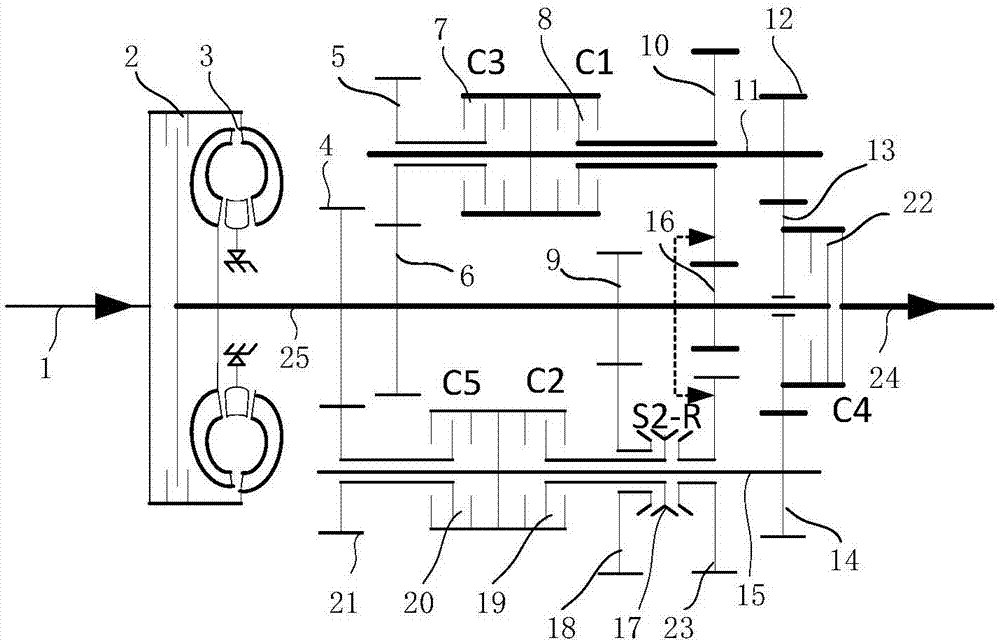

[0035] Embodiment 1: see attached figure 1 , a vertical five-speed automatic transmission for commercial vehicles, which includes: five wet clutches for gear shifting, and one synchronizer 17, which adopts a parallel shaft structure;

[0036] The parallel shaft structure includes: shaft A11, shaft B15 on both sides, and shaft C25 in the middle;

[0037] The five wet clutches for shifting are: the first clutch 8, the second clutch 19, the third clutch 7, the fourth clutch 22, and the fifth clutch 20;

[0038] The power from the engine is input through the input shaft 1 and transmitted to the shaft C25 through the torque converter 3 with the lock-up clutch 2; when the lock-up clutch 2 is closed, the power of the engine is directly transmitted to the shaft without the torque converter 3 Shaft C25; when the lock-up clutch 2 is disengaged, the power of the engine is transmitted to the shaft C25 after passing through the torque converter 3;

[0039] The shaft C25 is fixedly connec...

Embodiment 2

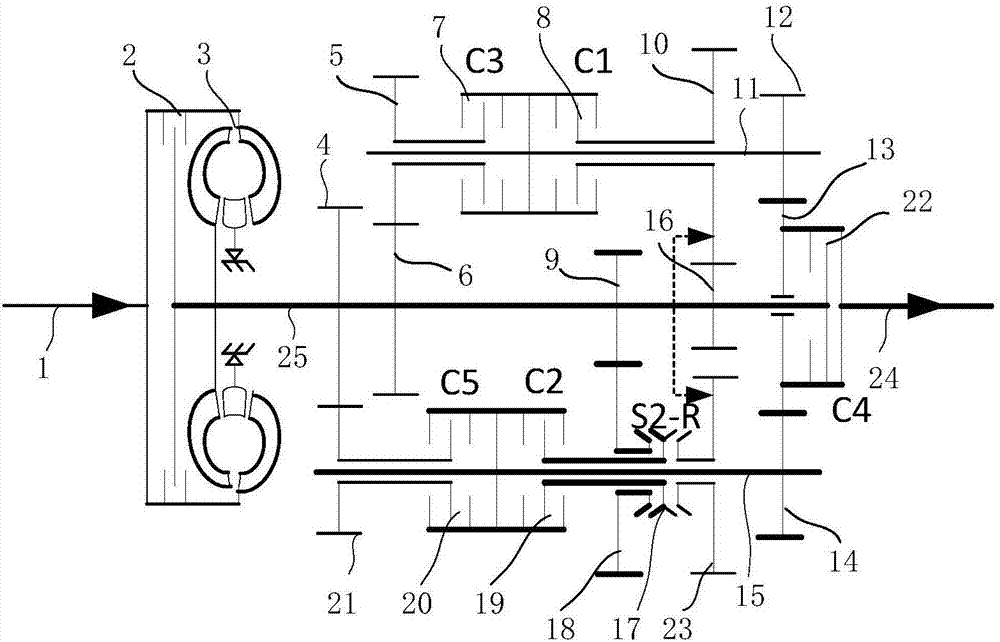

[0052] Embodiment 2, see attached Figure 8 , a vertical five-speed automatic transmission for commercial vehicles, which includes: 5 wet clutches for gear shifting, and 1 synchronizer 48, which adopts a parallel shaft structure;

[0053] The parallel shaft structure includes: shaft A34, shaft B49 on both sides, and shaft C30 in the middle;

[0054] The five wet clutches for shifting are respectively: the first clutch 38, the second clutch 46, the third clutch 39, the fourth clutch 50, and the fifth clutch 47;

[0055] The power from the engine is input through the input shaft 1 and transmitted to the shaft C30 through the torque converter 3 with the lock-up clutch 2; when the lock-up clutch 2 is closed, the power of the engine is directly transmitted to the shaft without the torque converter 3 Shaft C30; when the lock-up clutch 2 is disengaged, the power of the engine is transmitted to the shaft C30 after passing through the torque converter 3;

[0056] The shaft C30 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com