Biological 3D printer and sterilizing illuminating system for forming chamber of biological 3D printer

A technology of 3D printer and lighting system, which is applied in the direction of lighting devices, lighting and heating equipment, parts of lighting devices, etc. It can solve problems such as insufficient light, achieve the effects of avoiding damage, efficient sterilization without dead ends, and elimination of ozone tail gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

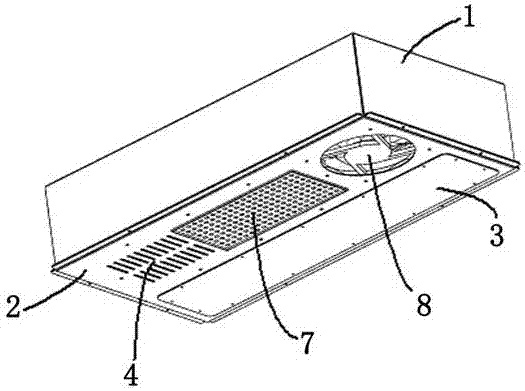

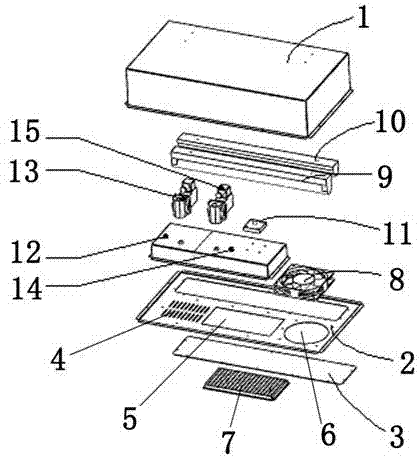

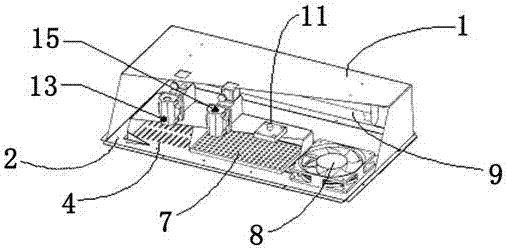

[0028] Such as Figure 1 to Figure 3As shown, a biological 3D printer molding room sterilization lighting system, which includes a housing 1 and a support plate 2 arranged at the bottom of the housing 1 and enclosing a cavity with the housing 1, the support plate 2 One side of the support plate is provided with a light diffusion plate 3, and the other side of the support plate 2 is provided with a first air inlet 4, a second air inlet 5 and an air outlet 6, and the first air inlet 4 is provided with a first A switch device, the second air inlet 5 is provided with an air handler 7 and a second switch device, the air outlet 6 is provided with an exhaust device 8, and the exhaust device 8 is a fan; on the inner wall of the top of the housing 1 An LED lamp 9 and an ultraviolet lamp 10 are provided at a position corresponding to the light diffusion plate 3 , and the ultraviolet lamp 10 is an ultraviolet lamp capable of generating short-wave ultraviolet rays (UVC) and vacuum ultravi...

Embodiment 2

[0039] A biological 3D printer, which includes the sterilization lighting system described in Embodiment 1, and also includes a 3D printing platform, a molding room, a temperature control system and a control system, the 3D printing platform is located in the molding room, and the sterilization Both the lighting system and the temperature control system are located above the molding chamber, and the 3D printing platform and the temperature control system are connected to the control system. The ventilation device 8, the LED lamp 9, and the ultraviolet lamp of the sterilization lighting system 10. The ozone concentration sensor 11, the first solenoid valve 13 and the second solenoid valve 15 are all connected to the control system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com