Preparation method of carbon-coating hollow crystal nickel oxide ethanol oxidation catalyst

A technology of ethanol oxidation and carbon coating, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, physical/chemical process catalyst, etc., can solve the problems of high price, easy poisoning, etc. Improved performance and better stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

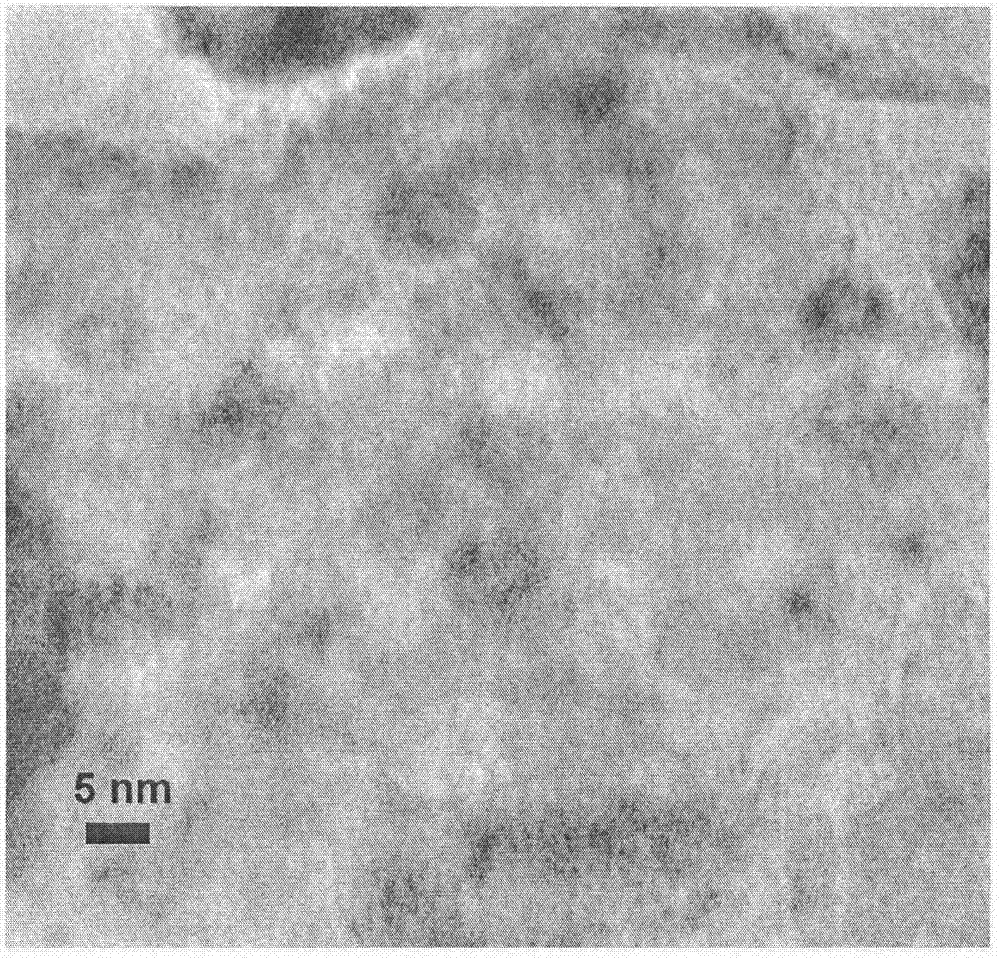

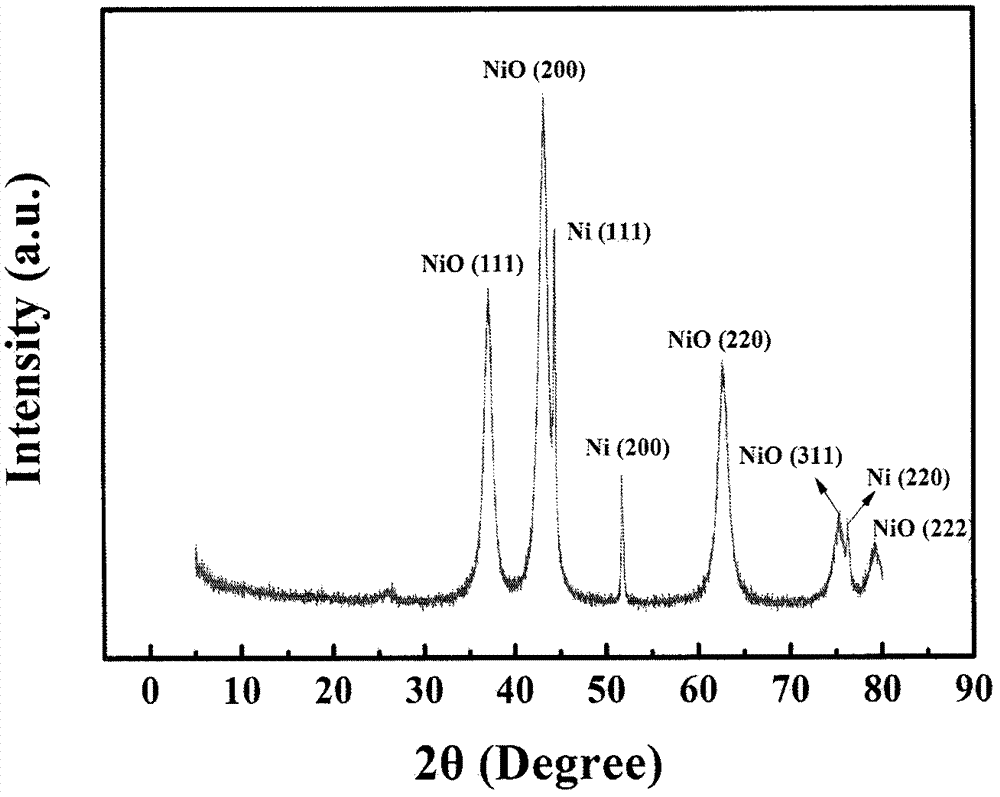

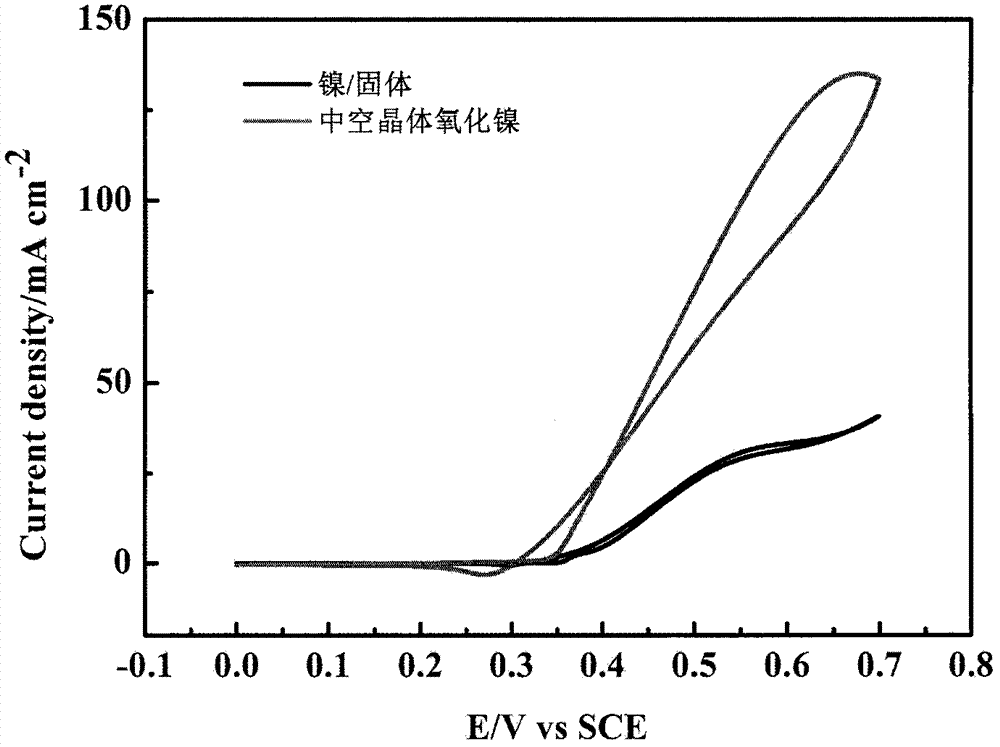

[0015] The preparation method of the ethanol oxidation catalyst of carbon-coated hollow crystal nickel oxide, the specific preparation process is as follows:

[0016] (1) Preparation of nickel / carbon solid:

[0017] Weigh 2g of glucose and 1.2g of nickel acetate, and then dissolve the mixture in 50mL of deionized water, stir for 2h, and then place it in a blast drying oven at 100°C for 10h. The completely dried solid was placed in a tube furnace, and calcined at 800°C with a heating rate of 3°C / min under a nitrogen atmosphere and kept for 2 hours to obtain a nickel / carbon solid.

[0018] (2) Preparation of crystal nickel oxide catalyst:

[0019] Weigh 1 g of nickel / carbon solid and place it in a crucible, then place the crucible in a muffle furnace for calcination at 350 °C for 2 h, with a heating rate of 1 °C / min. The obtained black powder was washed three times with deionized water, and dried at 40° C. for 12 hours to obtain a crystalline nickel oxide catalyst.

[0020] R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com