Horizontal force supporting mechanisms for working rollers of eighteen-roller mill

A support mechanism and technology for work rolls, applied in the direction of metal rolling mill stand, metal rolling stand, metal rolling, etc., can solve the problems of affecting the bending effect of intermediate rolls, difficulty in horizontal movement of work rolls, and huge side support structures, etc. , to achieve the effects of enhancing applicability and universality, increasing return on investment, and expanding varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

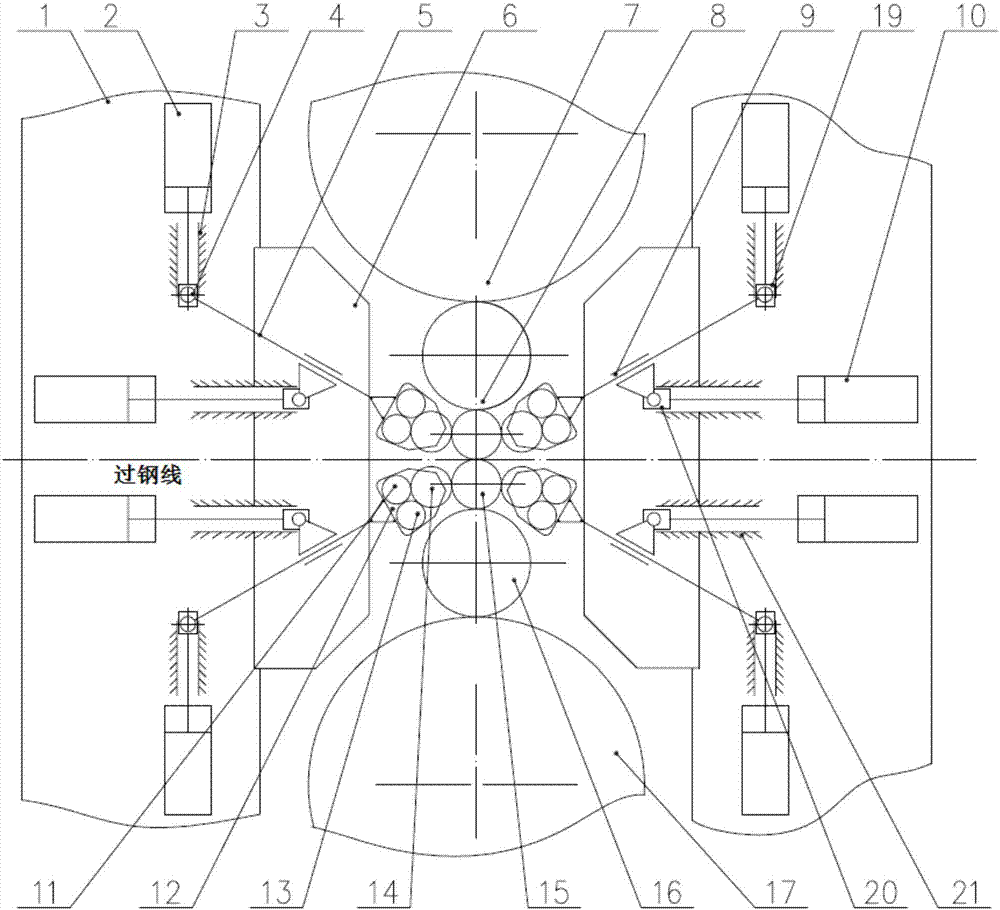

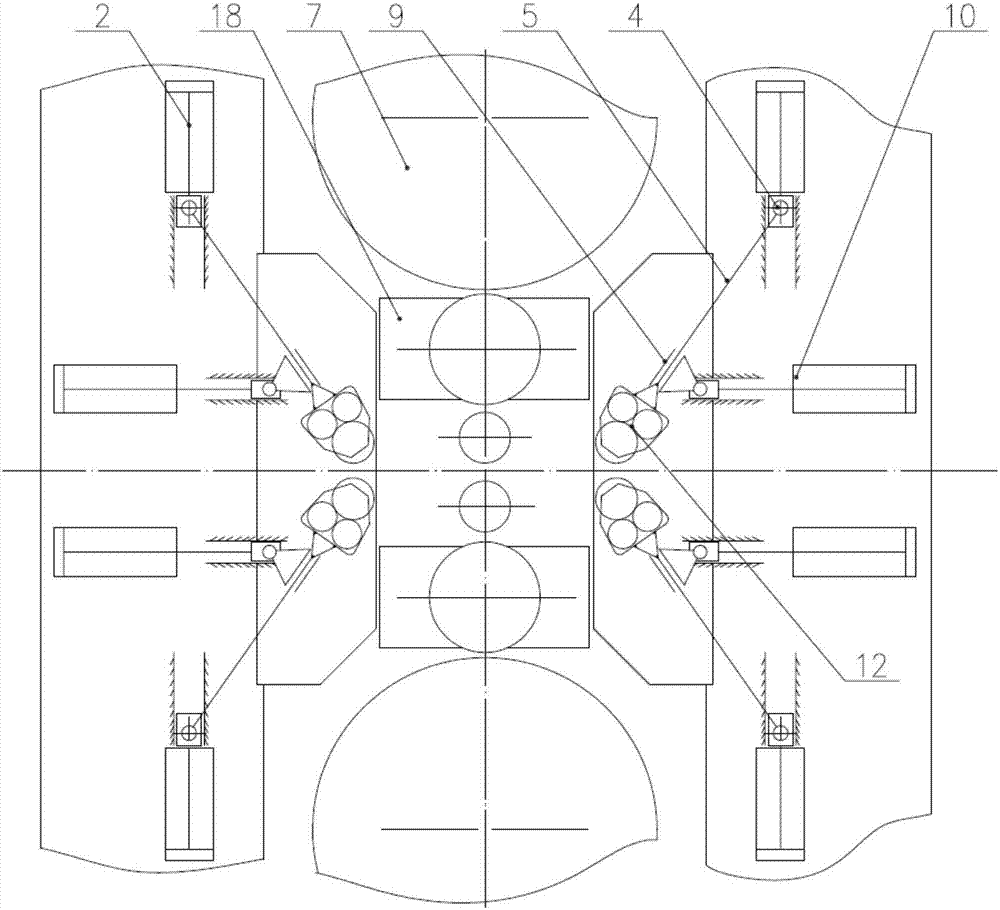

[0028] Shown below Figure 1-2 Embodiments of the present invention are further described:

[0029] In the present invention, the eighteen-high rolling mill is a cold rolling mill for rolling metal strips. In order to reduce the horizontal deflection of the work roll 15, lateral supports are added on both sides of the work roll 15, and the lateral support is a connecting rod. The slider structure can approach and finally support the work roll 15 along the fitting path under the action of the vertical push-pull hydraulic cylinder 2 (displacement sensor is installed inside) and the horizontal push-pull hydraulic cylinder 10 . The specific structure of its lateral support is as follows: the vertical push-pull hydraulic cylinder 2 is installed on the inner side of the frame archway 1, and its piston rod is connected with the vertical slider 19, and the vertical slider 19 can be fixed on the frame archway 1. Slideway 3 slides up and down, is designed with rotating hinge shaft 4 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com