Six-dimensional force measuring device and method based on viscous-elastic material polishing

A force measuring device and viscoelastic technology, which is applied in the field of six-dimensional force measuring device based on viscoelastic grinding and polishing, can solve problems such as force measuring error and machining accuracy, and achieve a small degree of coupling, accurate six-dimensional force, and universality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

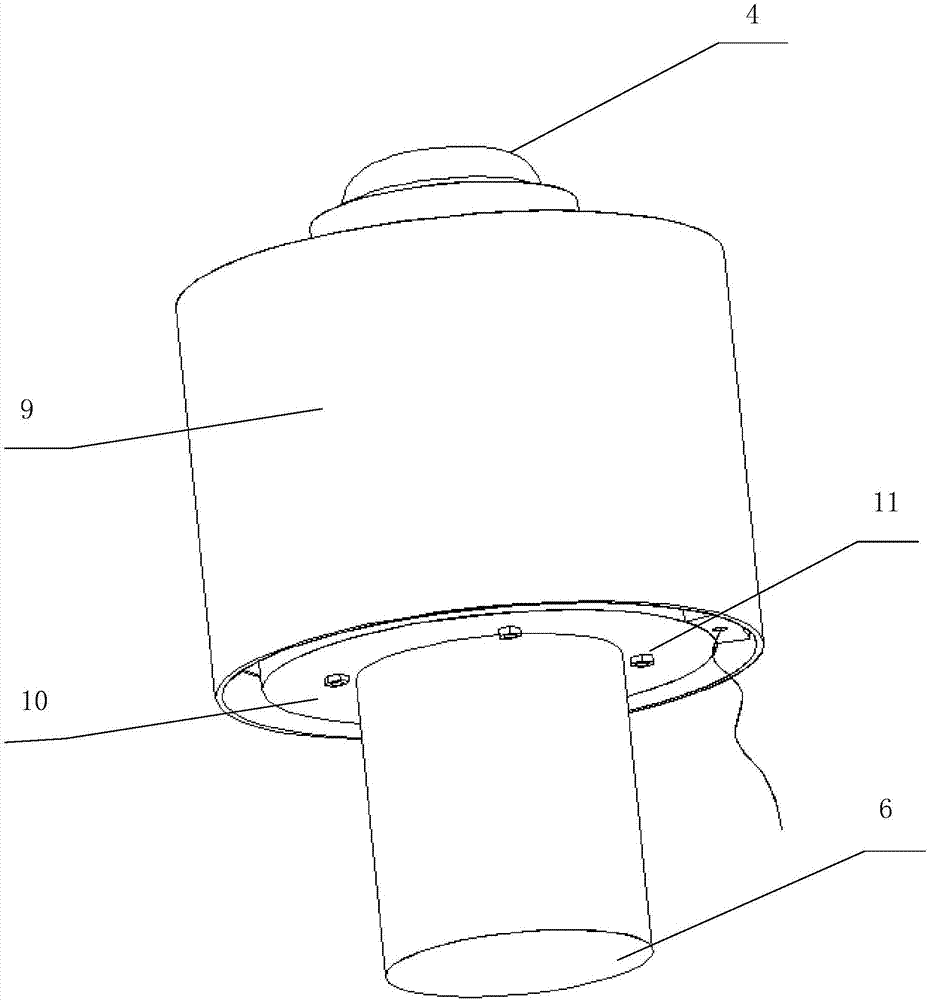

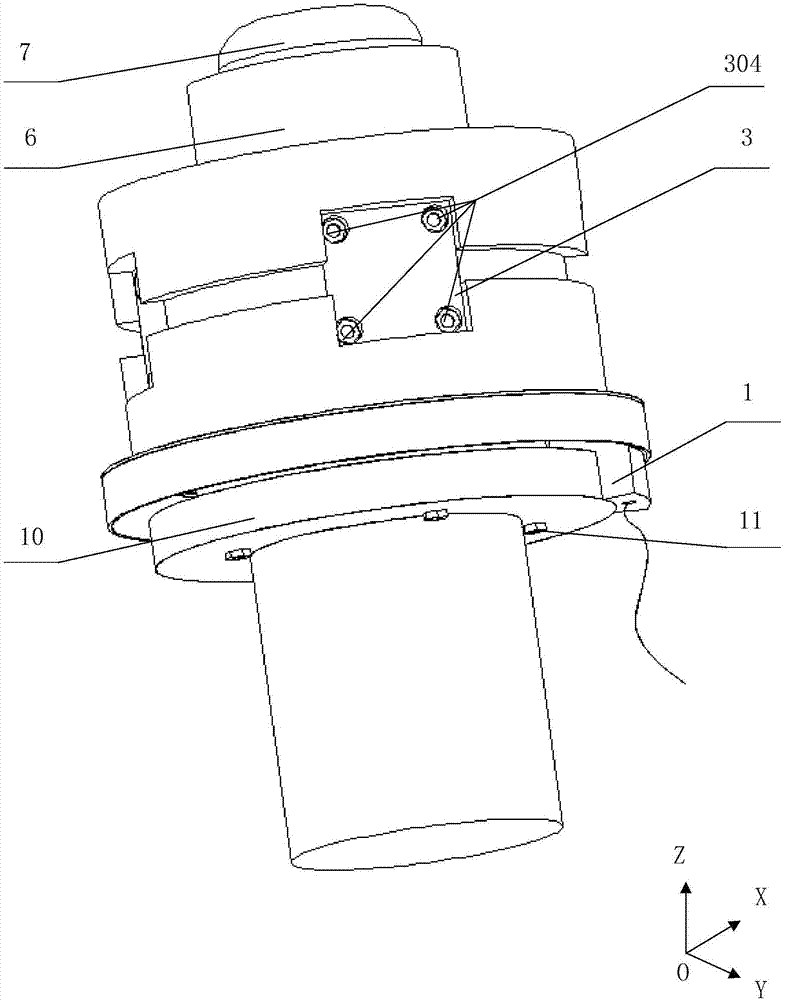

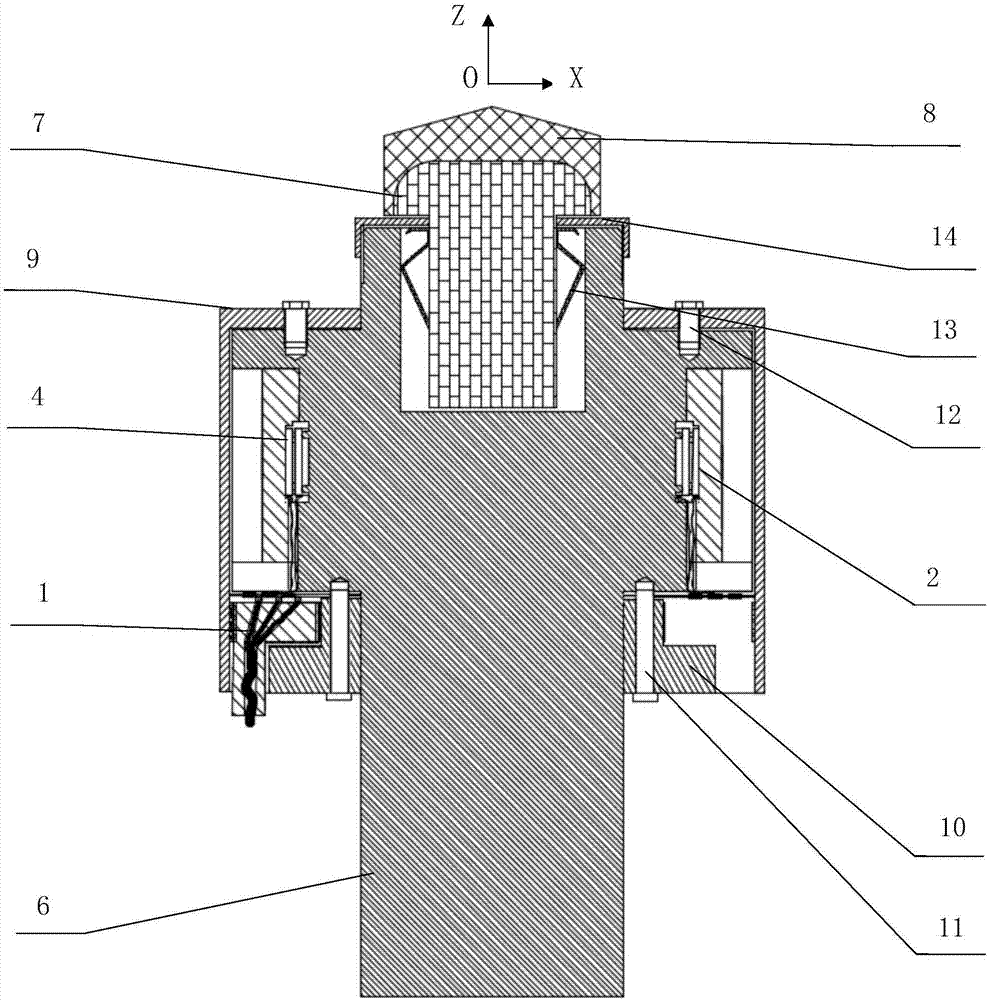

[0064] The device of the present invention is further described in detail in conjunction with the accompanying drawings. When processing curved surfaces with large curvature changes:

[0065] Depend on figure 1 , figure 2 , image 3 , Figure 4 As shown, the device is composed of an outgoing part 1, an elastic body 6, an outer sleeve 9, a lower cover 10, a force-sensitive device one 2, a force-sensitive device two 3, a force-sensitive device three 4, and a force-sensitive device four 5. Put the polishing head 7 with the viscoelastic material layer 8 into the circlip 13, then put the circlip 13 into the groove at the front end of the elastic main body 6, and the circlip 13 fits the inner wall of the groove at the front end of the elastic main body 6 contact, and the internal thread fastening cap 14 is threadedly connected to the front end of the elastic main body 6, and the outer wall of the front end of the elastic main body 6 is provided with threads to cooperate with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com