Oil sewage treatment system

A treatment system and technology for oily sewage, applied in water/sewage treatment, biological water/sewage treatment, flotation water/sewage treatment, etc., can solve problems such as the inability to achieve oil output, achieve low output of excess sludge, eliminate Good effect of sludge bulking and oil removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

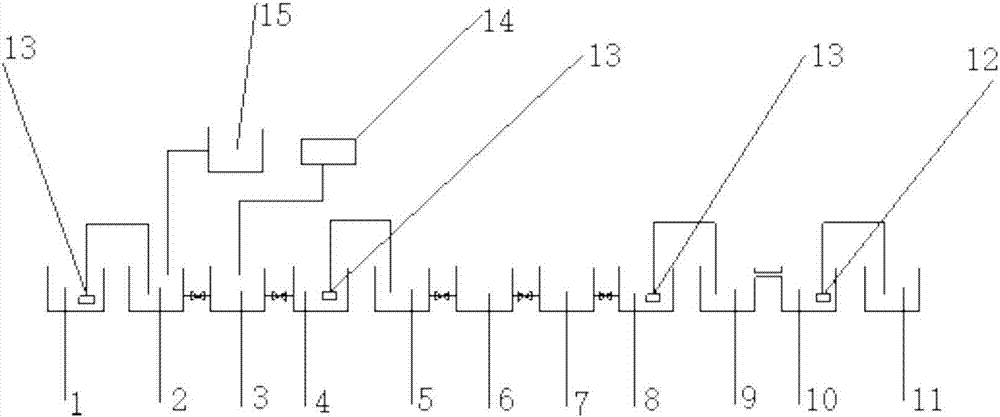

[0016] Such as figure 1 As shown, the oily sewage treatment system of the present invention is provided with a mechanical grille at the entrance of the regulating tank 1, the mechanical grille is used to remove suspended matter such as plastic bags, cloth strips), and the regulating pond 1 is used to adjust water quality and water quantity. An oil slick collector is arranged in the pool 1 to collect the slick oil on the liquid surface. Lift the sewage in the adjustment tank 1 to the cyclone degreaser 2 through the lifting pump 13, so that the oil and water are naturally separated under the action of centrifugal force, and the separated oily substances are discharged to the oil collection tank 15, and the remaining sewage is discharged to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com