Steel for wear-resistant steel bar, wear-resistant steel bar and preparation method thereof

A technology of wear-resistant steel and round steel, which is applied in the field of wear-resistant steel bars, can solve the problems of low tensile strength, low overall hardness, and low grinding efficiency, and achieve the effect of meeting the cost requirements and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The application provides a method for preparing the above-mentioned wear-resistant steel rod, comprising the following steps:

[0031]1) Prepare round steel: obtain round steel by steelmaking, continuous casting and continuous rolling, and the round steel includes the following components in weight percentage: 0.55%~0.65% of C; 0.2%~0.4% of Si; 0.60%~ 1.0% Mn; 0.9%~1.3% Cr; 0.15%~0.25% Mo; 0.1%~0.2% V; 0.01%~0.05% Ti; S≤0.020%; P≤0.020%; the rest is Fe and unavoidable impurities;

[0032] 2) sizing: the round steel obtained in step 1) is sizing according to the technical requirements of the rod mill to obtain a wear-resistant steel bar semi-finished product;

[0033] 3) Quenching: Heat the wear-resistant steel bar semi-finished product obtained in step 2) to 820°C-860°C in an intermediate frequency induction furnace, and then perform water quenching treatment, and the water quenching time is 5min-15min;

[0034] 4) Tempering: Temper the wear-resistant steel bar semi-f...

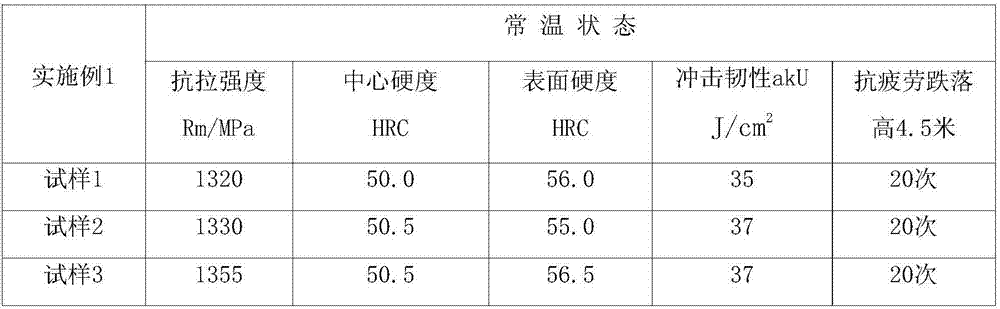

Embodiment 1

[0039] Taking a method for preparing a wear-resistant steel rod for a Φ100mm rod mill as an example, it includes the following steps:

[0040] 1) prepare round steel: obtain round steel by steelmaking, continuous casting and continuous rolling, and described round steel comprises the component of following percentage by weight: 0.59% C; 0.24% Si; 0.80% Mn; 1.1% Cr ; 0.19% Mo; 0.15% V; 0.03% Ti; 0.008% S; 0.012% P; the rest is Fe and unavoidable impurities;

[0041] 2) sizing: the round steel obtained in step 1) is sizing according to the technical requirements of the rod mill to obtain a wear-resistant steel bar semi-finished product;

[0042] 3) Quenching: Heat the wear-resistant steel rod semi-finished product obtained in step 2) to 840°C in an intermediate frequency induction furnace, and then perform water quenching treatment, and the water quenching time is 10 minutes;

[0043] 4) Tempering: Tempering the semi-finished wear-resistant steel bar obtained after water quench...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com