A-level fireproof flexible ceiling film and preparation method thereof

A technology for smallpox and soft film, applied in the field of building decoration materials, can solve the problems of inability to meet fire safety and environmental protection requirements, poor fire resistance, etc., to broaden the applicable types of pigments, improve flame retardancy, improve cleanability and resistance aging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

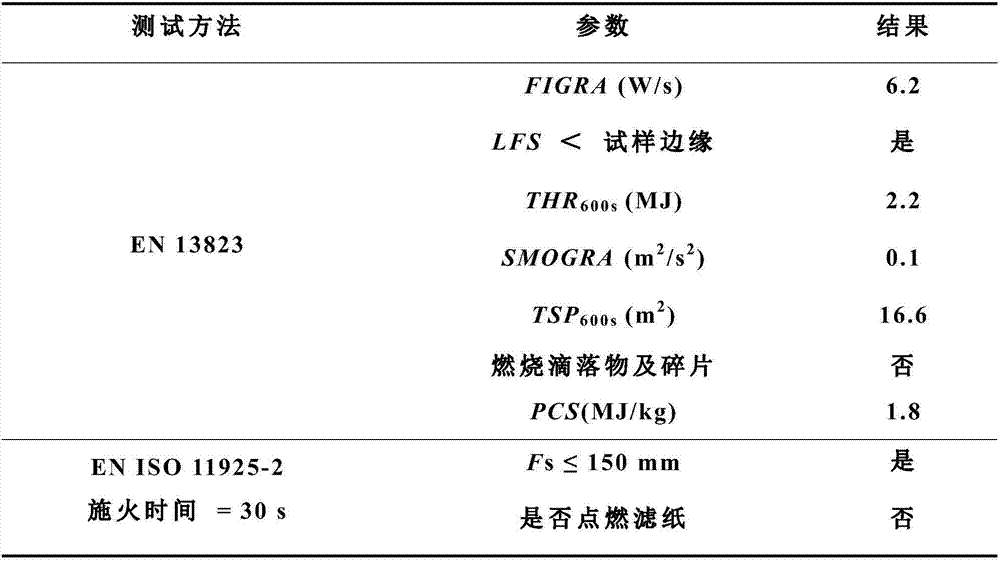

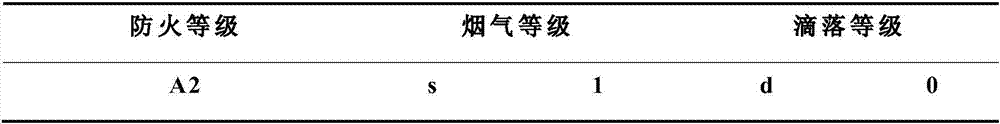

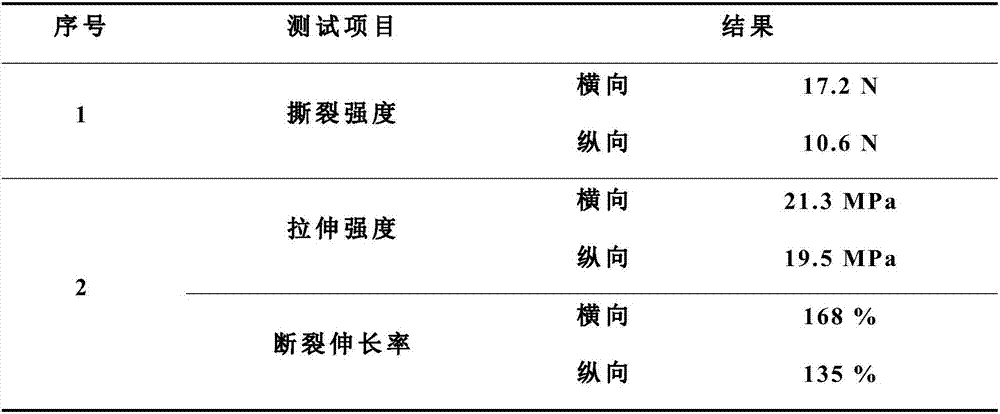

Examples

Embodiment 1

[0045] (1) Weigh each component according to the following proportions: 100.0 g of glass fiber fabric, 40.0 g of polytetrafluoroethylene dispersion, 4.5 g of titanium dioxide, 3.0 g of hollow glass microspheres and 5.0 g of polyvinyl alcohol;

[0046] (2) Dissolve 0.2g of coupling agent γ-(methacryloyloxy)propyltrimethoxysilane (KH-570) in 99.8g of absolute ethanol to form a solution, soak 100g of glass fiber fabric in absolute ethanol After soaking in the solution for 30 minutes, take out the glass fiber fabric and dry it in an oven at 120°C for 12 hours; put the glass fiber fabric treated with the coupling agent KH-570 into an ultrasonic cleaner containing acetone for 30 minutes to clean it. Remove the dirt on the surface of the glass fiber, and put it into an oven to dry for 10 hours to obtain a clean glass fiber fabric;

[0047] (3) Put the clean glass fiber fabric into the low-temperature plasma treatment device, use a quartz plate with a thickness of 1 mm as the medium, ...

Embodiment 2

[0067] Compared with Example 1, the amount of glass fiber fabric in the first step is changed to 120.0g, and other conditions remain unchanged.

Embodiment 3

[0069] Compared with Example 1, the amount of polytetrafluoroethylene dispersion in the first step is changed to 35.0g, and other conditions remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com