Diesel internal combustion engine oil-water mixing combustion device and process method thereof

An internal combustion engine, oil-water mixing technology, applied to internal combustion piston engines, combustion engines, engine components, etc., can solve problems such as unsatisfactory effects, achieve obvious energy saving effects, convenient use, and reduce air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

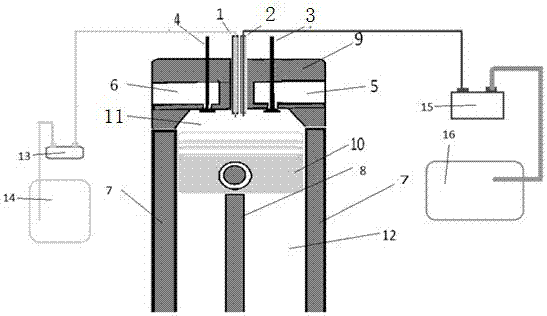

[0025] Embodiment 1, taking diesel internal combustion engine as example, traditional diesel internal combustion engine has four strokes when working: suction stroke, compression stroke, power stroke, exhaust stroke, and the present invention has five strokes: suction stroke, Compression stroke, first power stroke, second vaporization power stroke, exhaust stroke.

[0026] working principle:

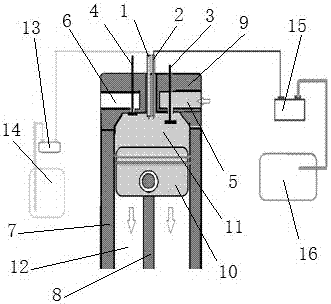

[0027] 1. Inhalation stroke: Like the traditional internal combustion engine, its task is to fill the cylinder with fresh air. The exhaust valve 4 is closed and the intake valve 3 is opened. When the intake stroke starts, the piston 10 moves downward at the top dead center, and the volume of the upper air chamber 11 above the piston 10 in the cylinder 7 gradually increases, causing the air pressure in the cylinder 7 to be lower than the pressure in the intake pipe 5, so , outside air just constantly fills into cylinder 7. (Such as image 3 shown).

[0028] 2. Compression stroke: dur...

Embodiment 2

[0032]Embodiment 2, taking a gasoline internal combustion engine as an example, the working principle of the gasoline internal combustion engine of the present invention is basically the same as that of the above diesel internal combustion engine. The difference is that diesel engines use fuel injectors to inject high-pressure ignition, and gasoline engines use spark plugs to ignite.

[0033] The characteristics of the present invention: the traditional four-stroke engine produces a large amount of heat when it is working, and instead of being utilized, the heat needs to be dissipated by water or wind. This heat is wasted in vain and has an immeasurable impact on the climate. When working, a large amount of exhaust gas is also released to pollute the environment. The present invention has five strokes, two of which are useful strokes (combustion work stroke, vaporization work stroke), and this vaporization work stroke starts to work after the combustion stroke is completed, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com