Onshore oscillating water column wave energy converter model testing device and method

A model test device and a technology of oscillating water column, which is applied in the direction of measuring device, fluid dynamics test, machine/structural component test, etc., can solve the problem of rarely considering the geometric change of the device model, the large number of device model components, and the lack of technical solutions and other issues, to achieve the effect of low test cost, expanding the scope of applicable working conditions, and high test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solutions of the present invention will be further described below, but the protection scope of the present invention is not limited to the implementation examples.

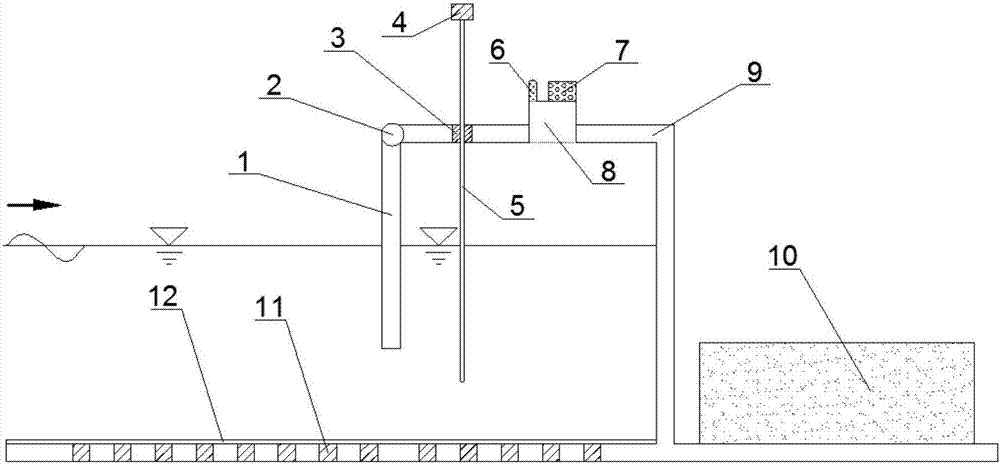

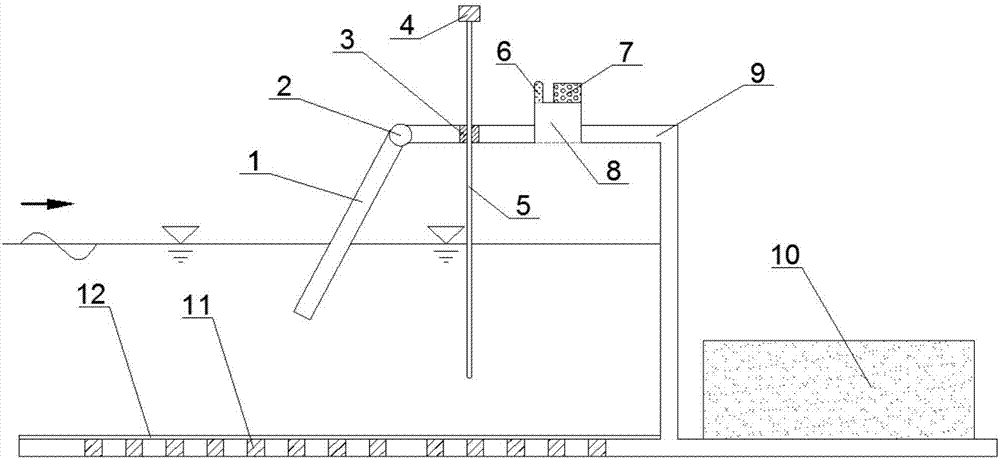

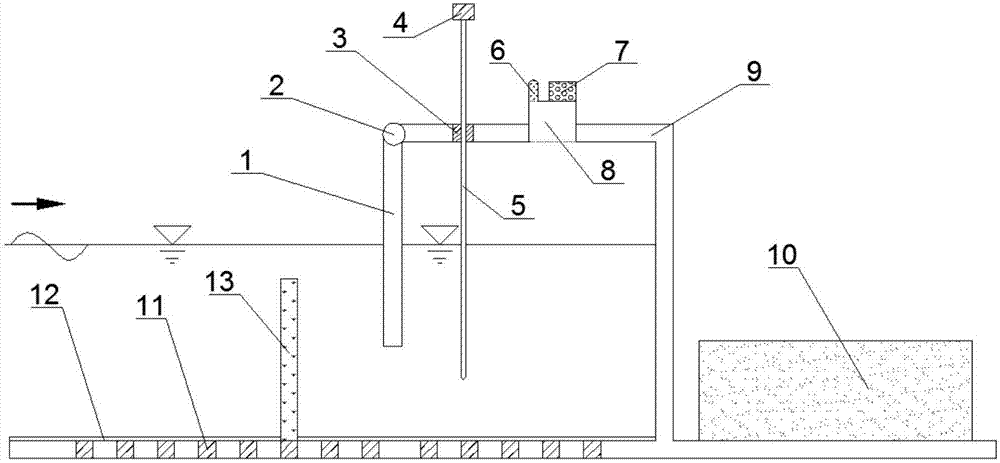

[0047] like figure 1 , Figure 7 As shown, a model test device for an oscillating water column wave energy conversion device, when no additional model is installed, consists of a front wall 1, a positioning screw 2, a rubber layer 3, an air pressure sensor 6, a wave height meter bracket 4, a wave height meter 5, Damping plate 7, air flow channel 8, model body 9, ballast block 10, card slot 11, water-proof bedding 12, shielding plate 18, and shielding plate interlayer 17; the interior of model body 9 is a hollow air chamber, and the two sides pass The visor 18 with the visor interlayer 17 is arranged to form a well-sealed air chamber structure. The wave-facing side of the front part of the model body 9 is connected to the front wall 1 through positioning screws 2, and a wave height meter 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com