Residue detection method of sodium tetradecyl sulfate

A technology of sodium tetradecyl sulfate and a detection method, applied in measuring devices, material analysis through electromagnetic means, instruments, etc., can solve low sensitivity, long experiment preparation process and analysis time, response sensitivity of specific compounds or their functional groups Restrictions and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 14

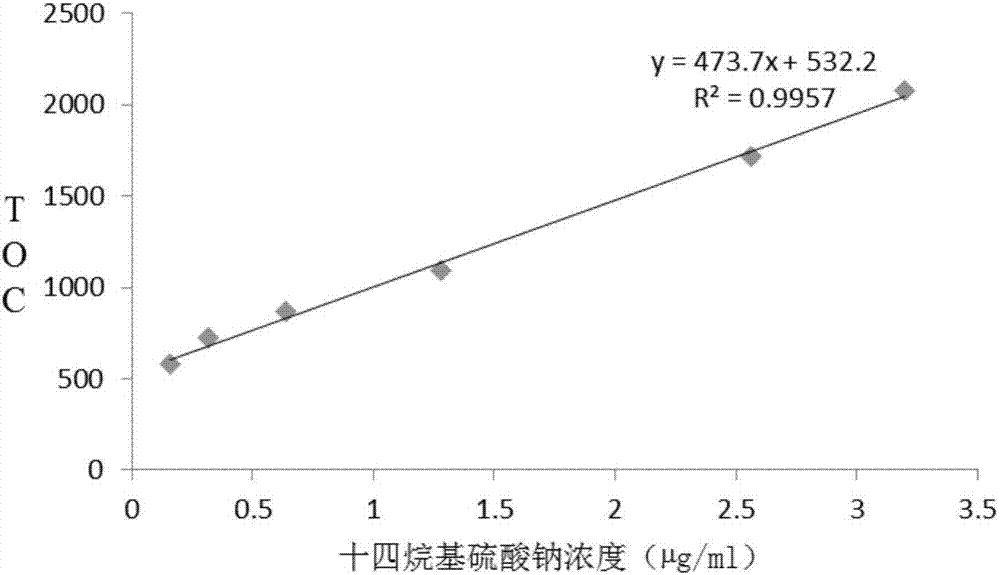

[0080] Example 1 Sodium Tetradecyl Sulfate Injection Online Analysis of Wiping Residue in the Return Air Vent of the Weighing Room

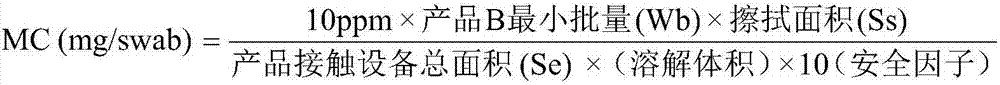

[0081] The equipment surface detection standard is calculated and converted based on the 10ppm standard (safety factor 10). Due to the large system area, some conversion results exceed the detection range, so the safety factor 10 in the 10ppm wiping limit calculation formula is removed and converted to the original standard (10ppm ) for testing, and the wiping residue limits are shown in Table 8.

[0082] Table 8

[0083]

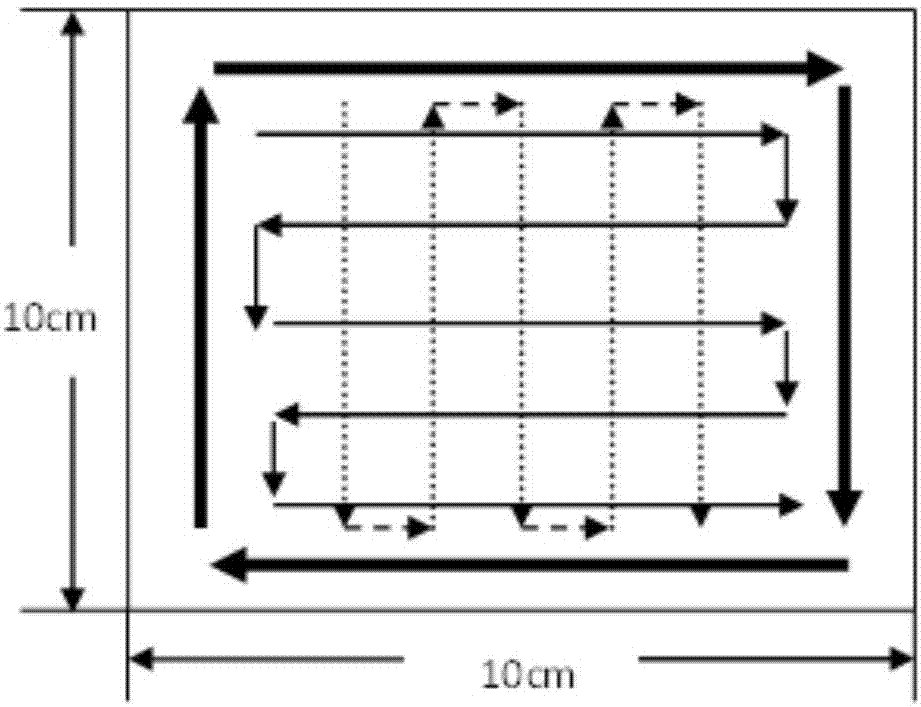

[0084] After the equipment is cleaned, use a TOC wipe cotton swab moistened with a solvent (such as water) to wipe the return air outlet of the weighing room. The wiping method is as follows: figure 1 As shown, the swab sampling area of each sampling site is about 100cm2 , and then dissolve the cotton swab in 100mL water for injection, pipette 50mL into a clean TOC tube, fully wash the TOC instrument for 3 times, after ...

Embodiment 2 10

[0085] Example 2 On-line Analysis of Sodium Tetradecyl Sulfate Injection in the Rinsing Water Residue of Liquid Mixing Tank

[0086] The leaching residue limit calculated by the formula is shown in Table 9

[0087] Table 9

[0088]

[0089] After the last cleaning of the equipment (cleaning with water), take 100mL of the eluent into a clean container, pipette 50mL into a clean TOC tube, fully clean the TOC instrument for 3 times, and inject blank water, Shake the sample in the sample tube, mix the sample evenly, keep it clear and colorless, put the sample tube into the TOC analyzer in order for detection, so as to measure the TOC value of the sample and obtain the information of the residual amount of the sample. During the detection, a total of 4 times were detected, the first time was discarded, and acid and oxidant were added (the mass concentration was 400mg / L respectively). The deviation was 2.65ppb and the relative standard deviation was 4.90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com