Optical fiber sound pickup, and preparation method and preparation device thereof

A technology for preparing devices and pickups, which is applied to measurement devices, optical signal detection transducers, instruments, etc., can solve the problems of large thermal expansion coefficient, low production efficiency, sensor temperature drift, etc., and achieves improved manufacturing efficiency, increased manufacturing cost, The effect of ensuring measurement sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

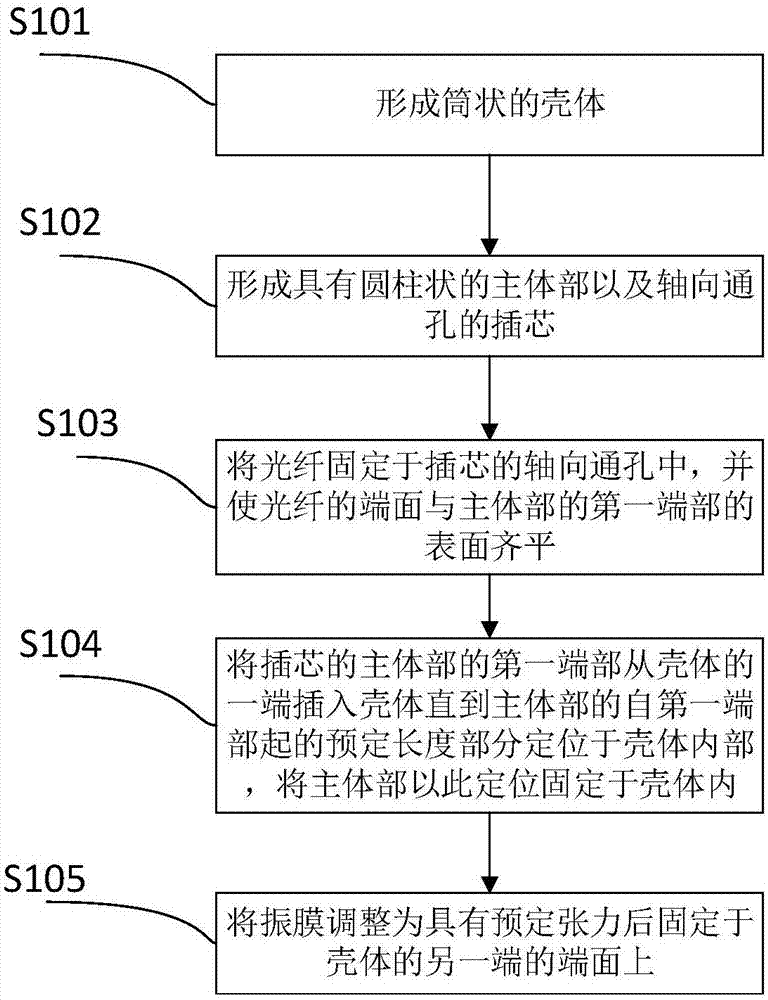

[0020] Various embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

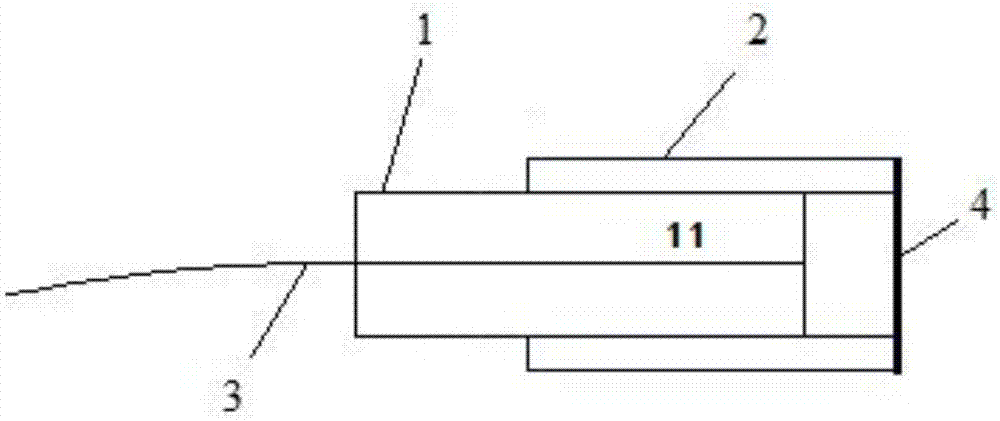

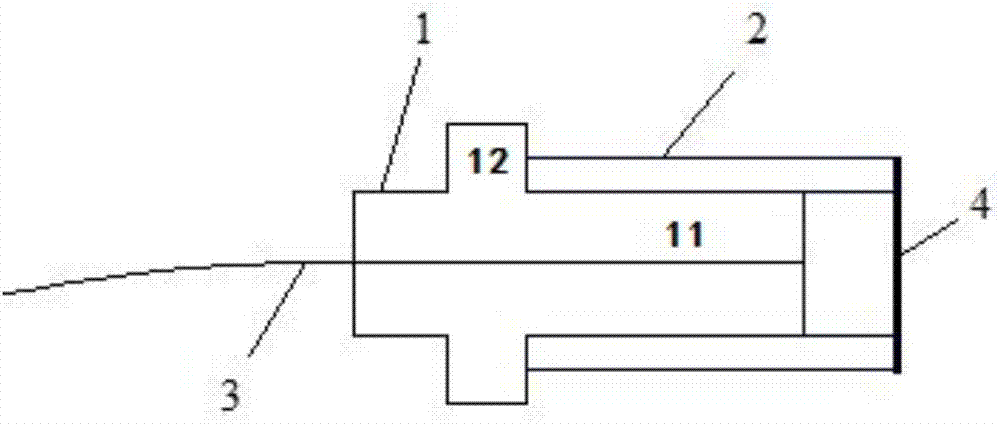

[0021] figure 1 It is a schematic structural view of the optical fiber pickup according to Embodiment 1 of the present invention, which is a schematic cross-sectional view taken along the central axis of the optical fiber pickup.

[0022] Such as figure 1 As shown, the optical fiber pickup according to Embodiment 1 of the present invention is composed of a ferrule 1 , a housing 2 , an optical fiber 3 and a diaphragm 4 . The casing 2 has a cylindrical structure, and the diaphragm 4 is fixed on one side of the casing 2 ( figure 1 on the right in the middle) on the end face. The ferrule 1 has a cylindrical main body 11, the part of the main body 11 is fixed in the housing 2 in cooperation with the inner wall of the housing 2, and the first end of the main body 11 close to the diaphragm 4 is predetermined from the diaphragm 4. A cavity is formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com