Grease composition and preparation method thereof

An oil and fat composition and oil technology, which are applied in the production/processing of edible oil/fat, edible oil/fat phase, edible oil/fat, etc., can solve the problem of high performance requirements of production equipment, small hardness change, and unsatisfactory nutrition. The concept of health, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

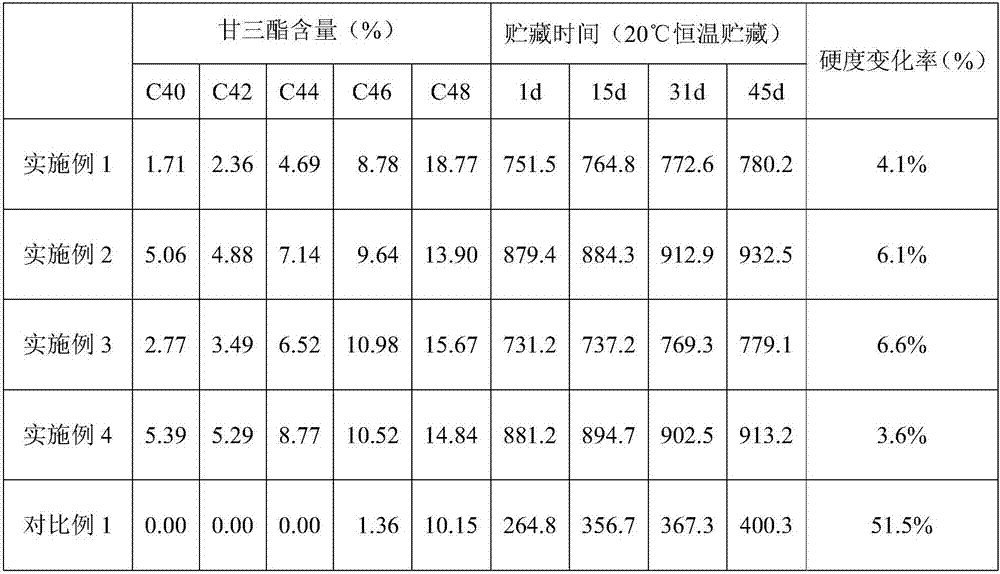

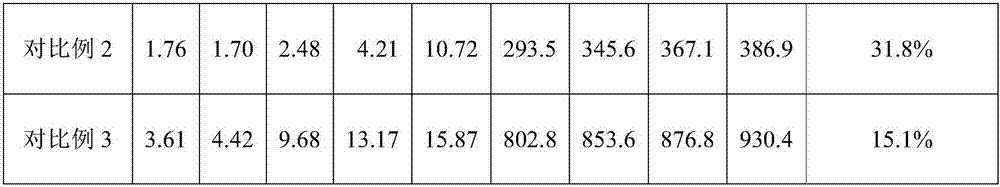

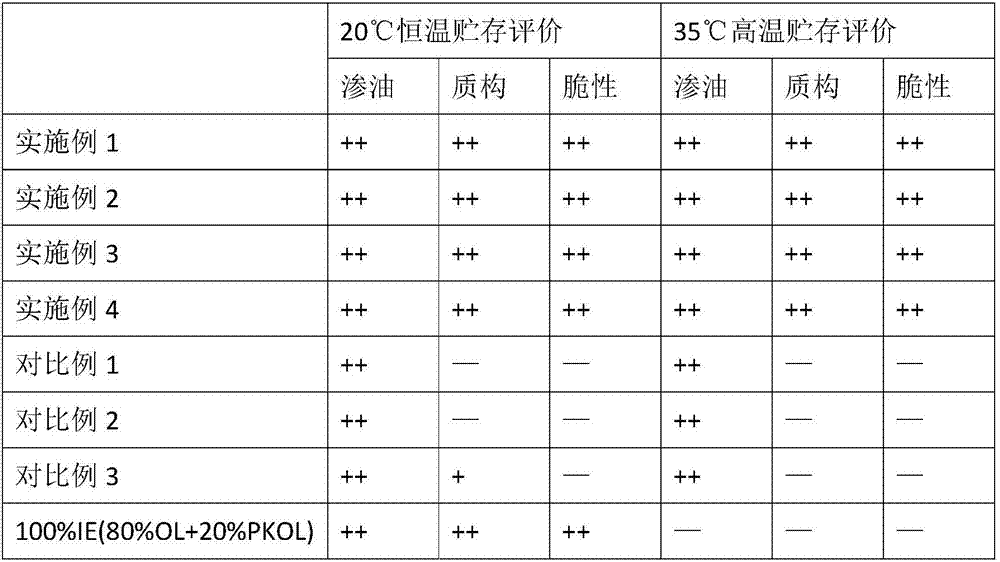

Examples

preparation example Construction

[0115] The preparation method of the oil composition of the present invention, said preparation method comprising: the step of providing oil A, B and the step of mixing oil A, B; wherein said oil A is lauric acid type oil and non-lauric acid type oil The mixed transesterified oil; fat B is a fat with a melting point higher than 30°C; the content of fat A is 65-95%, preferably 70%-90%; the content of fat B is 5%-35%, preferably 5%-20 %.

[0116] In one or more embodiments, the method also includes the step of mixing oil C, which is a mixed transesterified oil of stearyl laurate and non-stearyl laurate; the content of oil C is 0%- 20%, preferably 5%-15%.

[0117] In one or more embodiments, in the preparation method, fat A is composed of 10%-25% palm kernel oil or coconut oil, 15%-45% palm oil fractionated stearin, 10%-60% palm olein , 5%‐20% liquid vegetable oils and oils are mixed and transesterified.

[0118] In one or more embodiments, the liquid vegetable oil is one of s...

Embodiment 1

[0174] 67%IE (40%ST+30%OL+15%PKOL+15%SBO)+23%ST+10%OL

Embodiment 2

[0176] 90%IE(80%OL+20%PKOL)+8%ST+2%SBO

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com