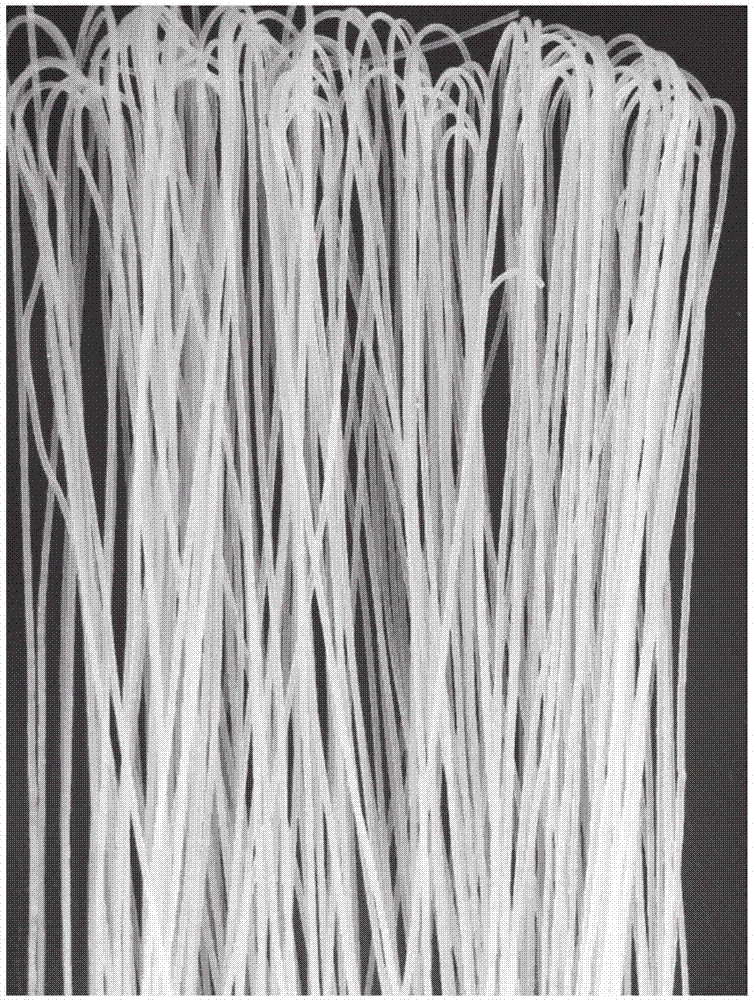

Manufacture method of polished round-grained rice noodles

A japonica rice noodle and a production method technology, applied in the direction of food science and the like, can solve the problems of difficult to squeeze silk and aging, affecting the taste of the japonica rice, high viscosity of the japonica rice, etc., and achieve the effect of improving the viscosity, easy to squeeze the silk, and rich rice flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] The preparation method of the japonica rice noodles of the present embodiment comprises the following steps:

[0070] (1) Preparation of germinated japonica rice: Take japonica rice with full grains, after hulling, remove impurities, mildew and discolored grains, etc.; put it into the germination unit after ozone sterilization and cleaning, and control the germination temperature at about 30°C (30±2°C) , the humidity is 80%, the germination time is 48 hours, dried, and the rice is milled to obtain germinated japonica rice;

[0071] (2) Soaking: Soak the germinated round-grained rice for 10 hours according to the rice-water ratio of 1:2, so that the rice grains can fully absorb water and swell, and after soaking, the rice grains can be crushed as soon as they are pinched;

[0072] (3) Centrifugal dehydration, rotary cutting pulverization: the raw material obtained in step (2) is centrifugally dehydrated in a centrifugal dehydrator for 8 minutes (the moisture content of t...

Embodiment 2

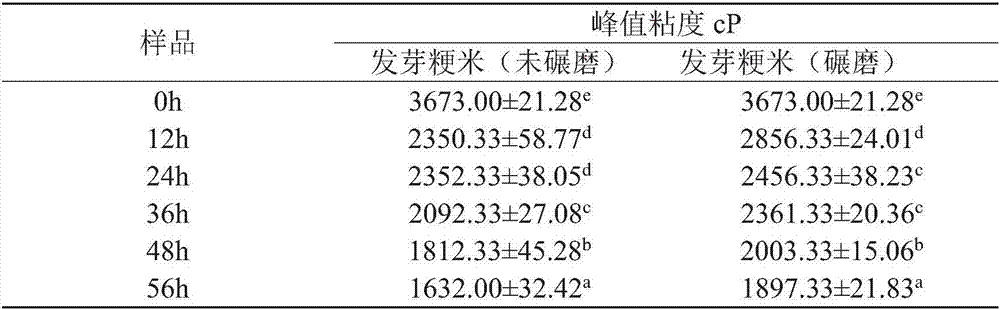

[0078] Compared with Example 1, the only difference is that in step (1), the rice milling process is not performed; that is, the germinated japonica brown rice is dried to obtain the germinated japonica rice directly. The present inventor is by testing the peak viscosity of embodiment 1 and embodiment 2 germinated japonica rice process, and data is shown in table 1; Table 1

[0079]

[0080] Note: The data are the mean ± standard deviation of three determinations; different letters in the same column indicate significant differences (P<0.05)

[0081] It can be seen from Table 1 that germination can significantly reduce the viscosity of japonica rice flour. Germination treatment had a great influence on the peak viscosity of japonica rice noodles, which was the viscosity of japonica rice noodles during thermal processing, and the peak viscosity would decrease significantly with the increase of germination time.

Embodiment 3

[0083] The preparation method of the japonica rice noodles of the present embodiment comprises the following steps:

[0084] (1) Soaking: Soak the japonica rice for 12 hours according to the rice-water ratio of 1:2, so that the rice grains can fully absorb water and swell. After soaking, the rice grains can be crushed as soon as they are pinched;

[0085] (2) Centrifugal dehydration, rotary cutting type pulverization: the raw material obtained in step (1) is centrifugally dehydrated in a centrifugal dehydrator for 10 minutes, then pulverized with a rotary cutting type pulverizer, and crosses an 80-mesh sieve to obtain japonica rice flour;

[0086] (3) Infrared pregelatinization treatment: mix the japonica rice flour obtained in step (2) with 30% water equivalent to the weight of the japonica rice flour, stand still at room temperature for 20 minutes to balance the moisture, and then place it in an infrared drying box at a temperature of 100°C , 3 minutes under infrared power 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com