Modified chromatographic apparatus and method of using same in continuous-flow chromatography

A chromatography device and flow chromatography technology, applied in separation methods, chemical instruments and methods, biochemical cleaning devices, etc., can solve the problems of inability to identify, stay in the design stage, and AKTApure cannot be implemented.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

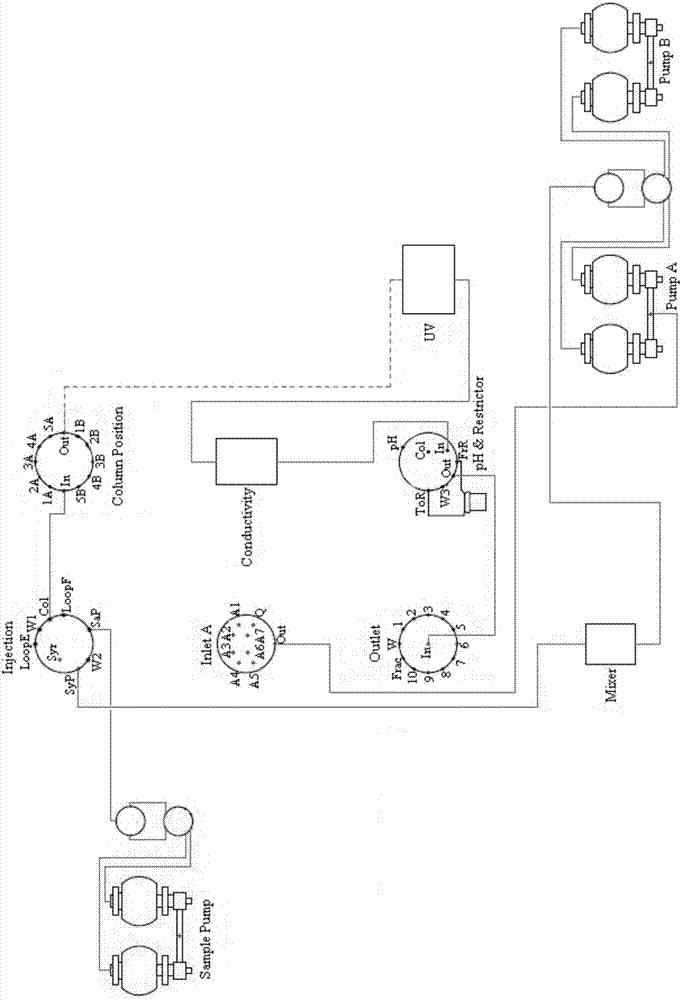

[0054] An improved AKTApure chromatography device, including standard AKTApure (pure M) configuration: system pump (A pump, B pump), mixing tank, sample pump, system pump A pump inlet valve (Inlet A), injection valve (Injection valve) Valve), first column valve, first UV detector, conductivity detector, pH detector, backpressure valve, and outlet valve; in addition, includes:

[0055] Three multi-function valves or mixer valves, which are defined in the system as Versatile Valve 1 (V1), Versatile Valve 2 (V2) and Versatile Valve 3 (V3); a second column valve or a Loop ring Valve, and define it as Loop Valve (L) in the system; and three columns No. 1 column, No. 2 column and No. 3 column;

[0056]Among them, the Out position of the first column valve is connected to the LoopF position of the injection valve, 1A and 3B of the first column valve are connected to the No. 1 position of V1 with a tee, and 2A and 1B of the first column valve are connected with a tee Connect to No....

Embodiment 2

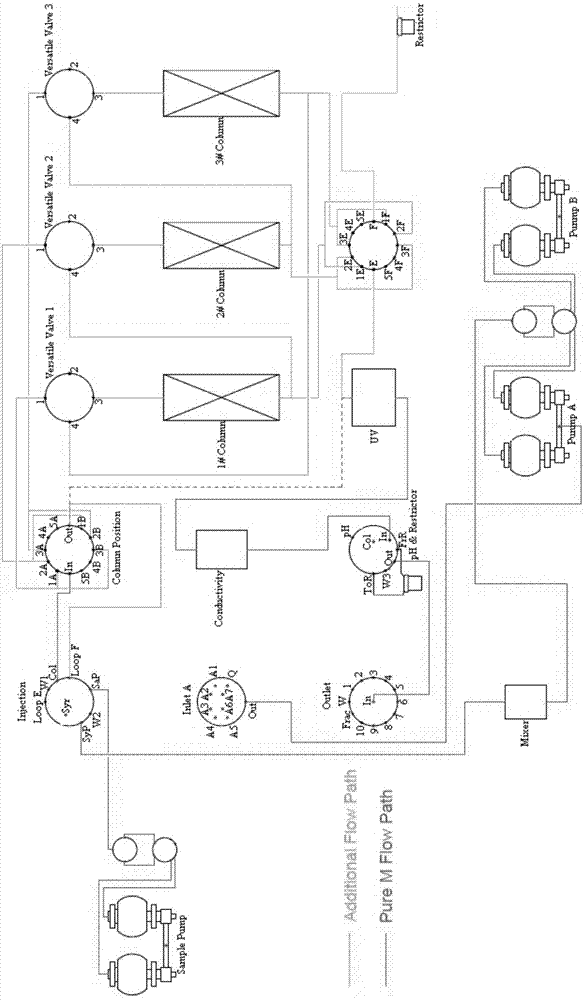

[0060] An improved AKTApure chromatography device, including standard AKTApure (pure M) configuration: system pump (A pump, B pump), mixing tank, sample pump, system pump A pump inlet valve (Inlet A), injection valve (Injection valve) Valve), first column valve, UV detector, conductivity detector, pH detector, back pressure valve and outlet valve; also includes:

[0061] Three multi-function valves or mixer valves, which are defined in the system as Versatile Valve 1 (V1), Versatile Valve 2 (V2) and Versatile Valve 3 (V3); a second column valve or Loop ring valve , and define it as Loop Valve (L) in the system; a second UV detector, and define it as UV 2nd in the system; and three columns No. 1 column, No. 2 column and No. 3 column;

[0062] Among them, the Out position of the first column valve is connected to the LoopF position of the injection valve, 1A and 3B of the first column valve are connected to the No. 1 position of V1 with a tee, and 2A and 1B of the first column...

Embodiment 3

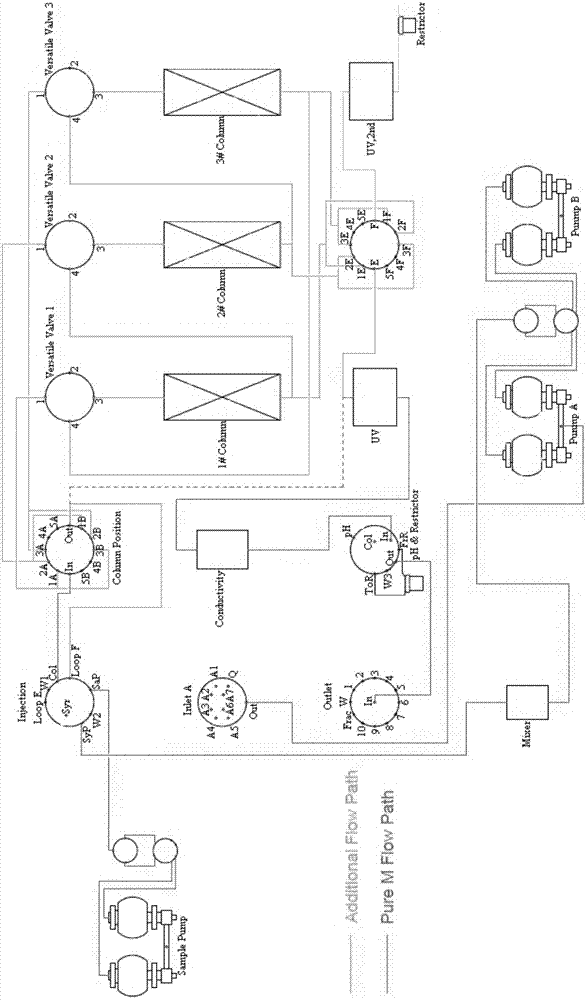

[0066] An improved AKTApure chromatography device, including standard AKTApure (pure M) configuration: system pump (A pump, B pump), mixing tank, sample pump, system pump A pump inlet valve (Inlet A), injection valve (Injection valve) Valve), Column Valve, UV Detector, Conductometric Detector, pH Detector, Backpressure Valve, and Outlet Valve; in addition, includes:

[0067] Three multi-function valves or mixer valves, which are defined in the system as Versatile Valve 1 (V1), Versatile Valve 2 (V2) and Versatile Valve 3 (V3); a second column valve or Loop ring valve , and define it as Loop Valve (L) in the system; a second UV detector, and define it as UV 2nd in the system; and three columns No. 1 column, No. 2 column and No. 3 column;

[0068] Among them, the Out position of the first column valve is connected to the LoopF position of the injection valve, 1A and 3B of the first column valve are connected to the No. 1 position of V1 with a tee, and 2A and 1B of the first co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com