Method for treating wastewater and increasing quality till reaching standard on basis of activated carbon reproducible mode and system

A technology of activated carbon and granular activated carbon, which is applied to the system field used in the above method, can solve the problems of high cost, consumption and the like, and achieve the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

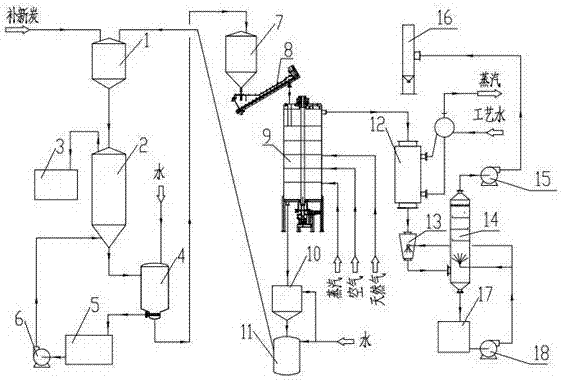

[0039] Taking the treatment of coking wastewater as an example, the system for treating coking wastewater using granular carbon in a renewable manner includes an adsorption tower 2, and the outlet on the upper part of the adsorption tower 2 is connected to a clear water pool;

[0040] The lower part of the adsorption tower 2 has a coking wastewater inlet, which leads to the raw wastewater pool;

[0041] The outlet at the lower part of the adsorption tower 2 is connected with a waste carbon washing tank 4, and an outlet at the lower part of the waste carbon washing tank 4 is connected with the raw waste water pool;

[0042] Another outlet waste carbon feed tank 7 at the lower part of the waste charcoal washing tank 4 is connected, and there is a dehydration screw conveying device 8 below the outlet of the waste charcoal feed tank 7 to transport the waste charcoal to the multi-stage regeneration furnace 9;

[0043] The outlet at the bottom of the multi-stage regeneration furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com