Reflection-type ultrasonic shot-peening strengthening device for inner hole surface

An ultrasonic shot peening and strengthening device technology, which is applied in the field of parts surface strengthening equipment, can solve the problems of large environmental pollution, high energy consumption, and large shot peening consumption, and achieve the effects of low environmental pollution, low energy consumption, and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

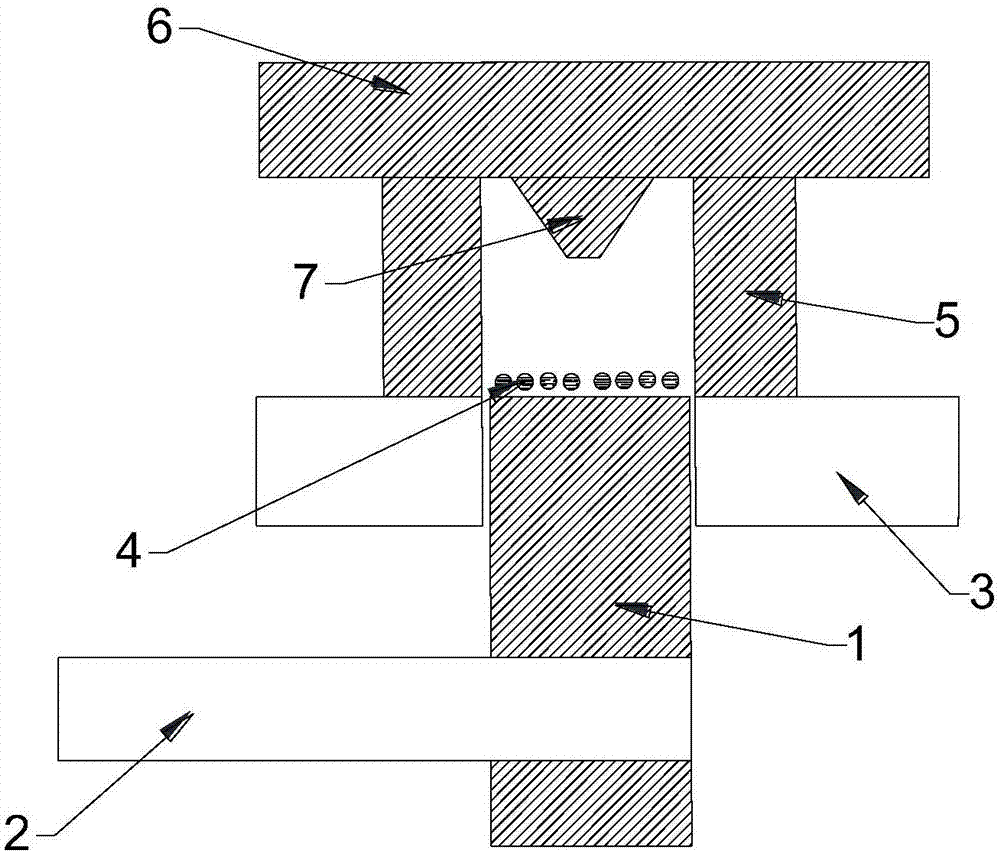

[0020] Such as figure 1 As shown, the ultrasonic shot peening device on the surface of the inner hole includes a cover plate 6, a workbench 3 and an ultrasonic vibrating head 1. The part 5 to be processed has a through hole, and the working table 3 is provided with a positioning hole. The ultrasonic vibrating head 1 consists of The mechanical arm 2 is clamped and installed in the positioning hole. The mechanical arm 2 clamps the ultrasonic vibration head 1 and can move up and down along the axis of the positioning hole. By controlling the mechanical arm 2, the depth of the ultrasonic vibration head 1 entering the through hole can be changed. The ultrasonic vibration head 1 is connected to the transducer through the horn, and the transducer is electrically connected to the ultrasonic generator. After the ultrasonic generator is powered on, a high-frequency electrical oscillation signal of 15-40KHz is sent to the transducer, and the transducer will receive The received electric ...

Embodiment 2

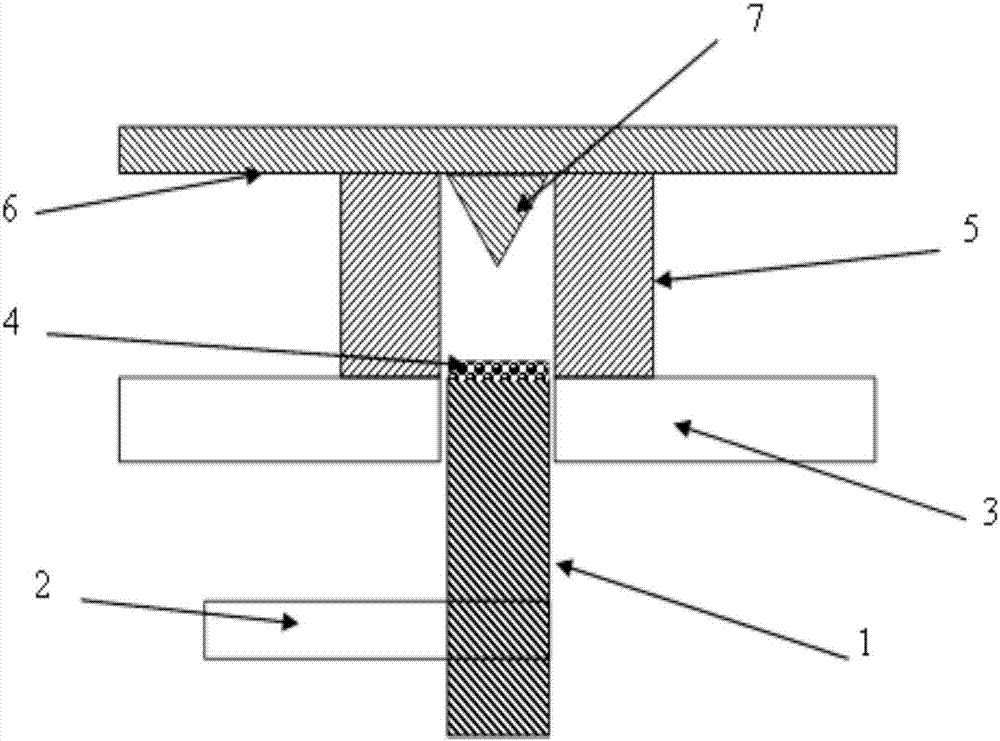

[0025] Such as figure 2 As shown, the ultrasonic shot peening device on the surface of the inner hole includes a cover plate 6, a workbench 3 and an ultrasonic vibration head 1. The difference between this embodiment and Embodiment 1 is that in this embodiment, the convex part 7 is in this embodiment The middle is an inverted cone, and the taper of the cone is preferably 45°. Compared with the convex part 7 of the inverted frustum of the conical body in Example 1, the convex part 7 of this embodiment can reflect more shot blasting 4 and hit the hole wall of the through hole, which has a better strengthening effect on the hole wall of the through hole. In Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com