Ground compaction machine, in particular rubber-tired roller, having a wheel cover, and wheel cover

A technology of rubber tires and compactors, which is applied in the field of rubber tire road rollers, can solve the problems of enlarged overall size of ground compactors, complex and unfavorable precise steering of ground compactors, etc., and achieve simplified operation, improved heat insulation, handling and transportation easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Similar or equivalent parts are indicated by the same reference numerals throughout the drawings. Repeated components are not necessarily shown separately in each figure.

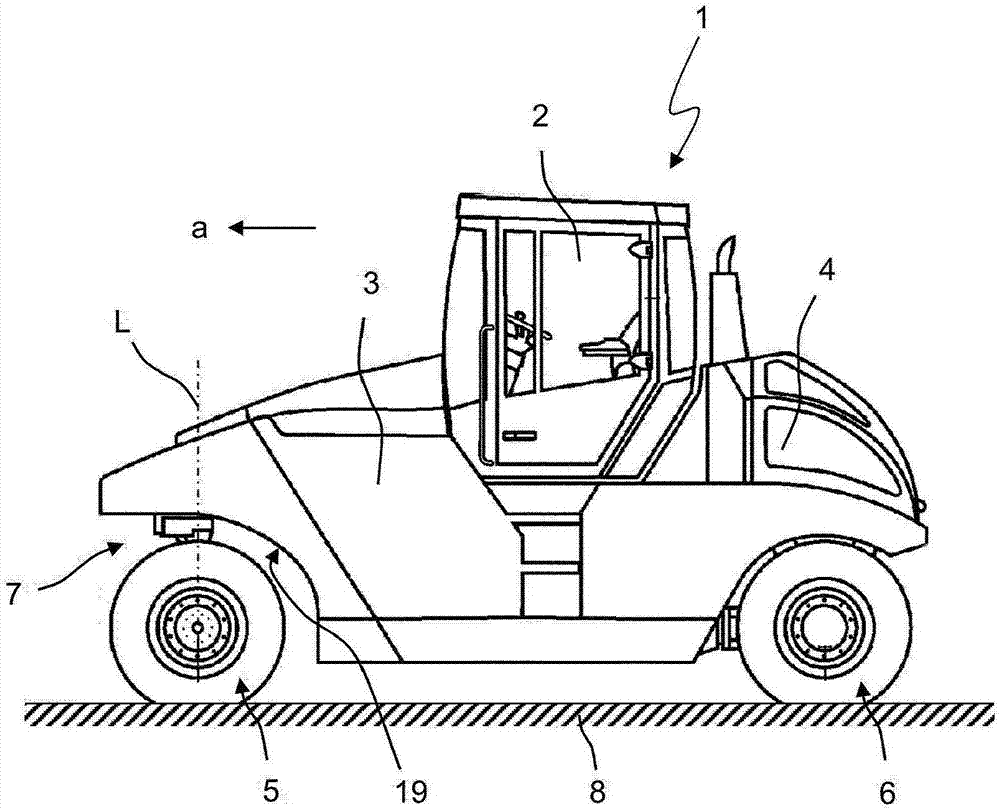

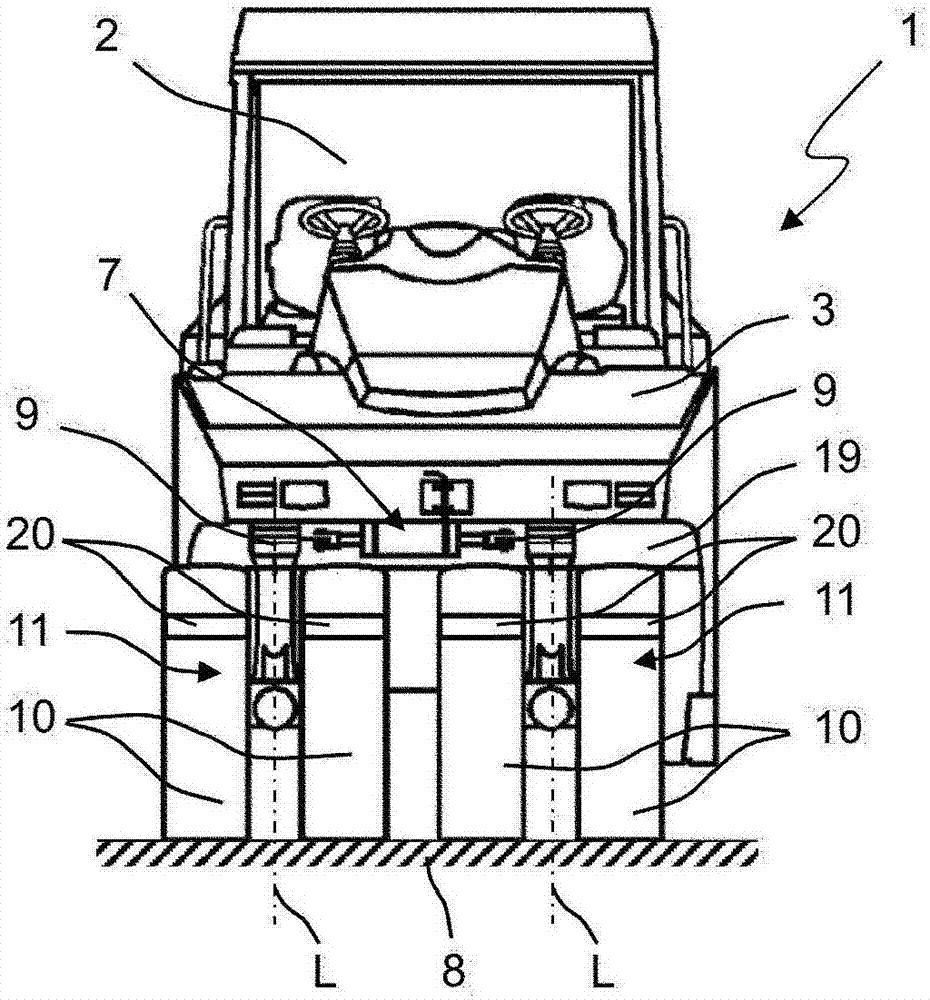

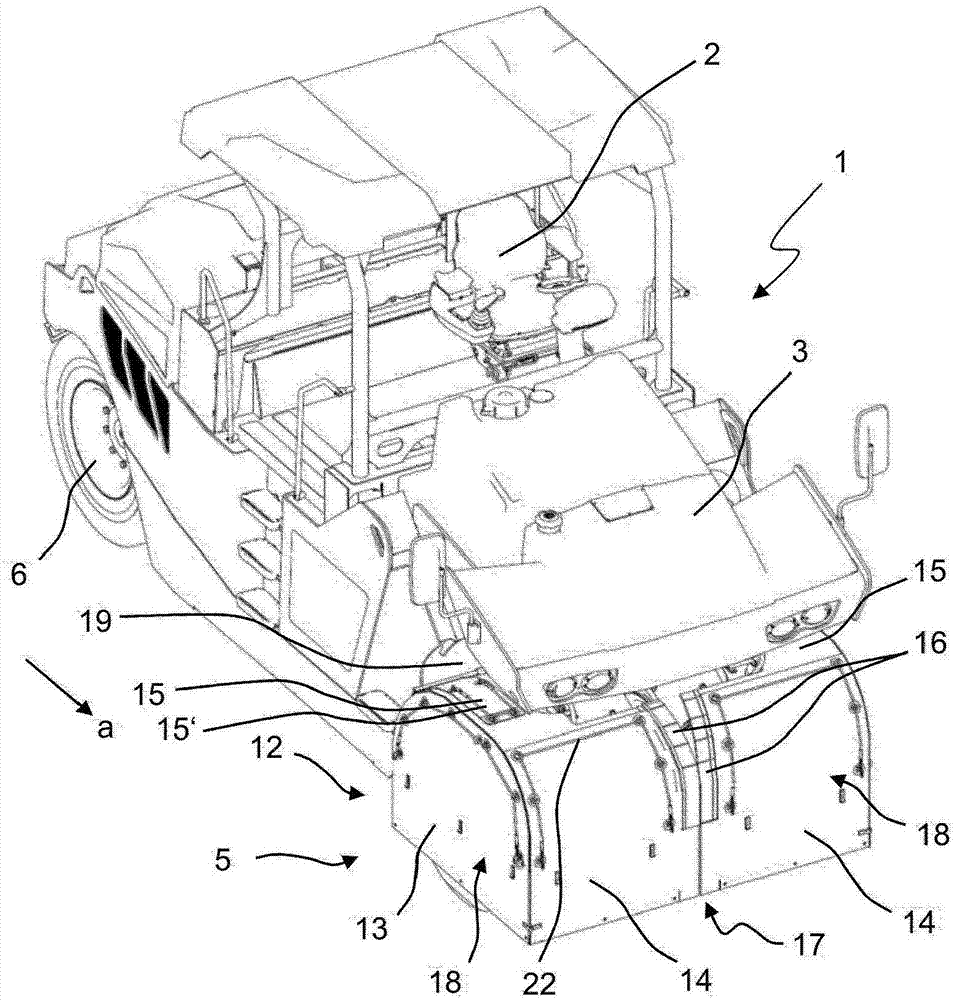

[0042] figure 1 with figure 2 A universal ground compactor 1 with an operator's platform 2 and a frame 3 is shown. Furthermore, the ground compactor 1 comprises a chassis driven by a propulsion unit 4 , mostly a diesel combustion engine, which, as shown in the exemplary embodiment, comprises a front chassis section 5 and a rear chassis section 6 . During the working operation of the ground compactor 1 , it moves along the working direction a over the ground 8 and compacts it. figure 2 Details of the front chassis section 5 are shown. The front chassis part 5 comprises a steering device 7 and two chassis units 11 . The chassis units 11 each comprise two wheels 10 and a steerable support column 9 . The undercarriage units 11 are each designed to be rotatable about two vertical steering axes L e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com