A device and process for repairing the cylinder barrel of an oil cylinder

A cylinder and oil cylinder technology, which is applied in the field of equipment for repairing oil cylinders and cylinders, can solve problems such as pollution caused by the environment, unsatisfactory repairing effect of oil cylinders and cylinders, etc., and achieves the advantages of reducing damage and pollution, improving brightness and hardness, and reducing investment costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in conjunction with the accompanying drawings.

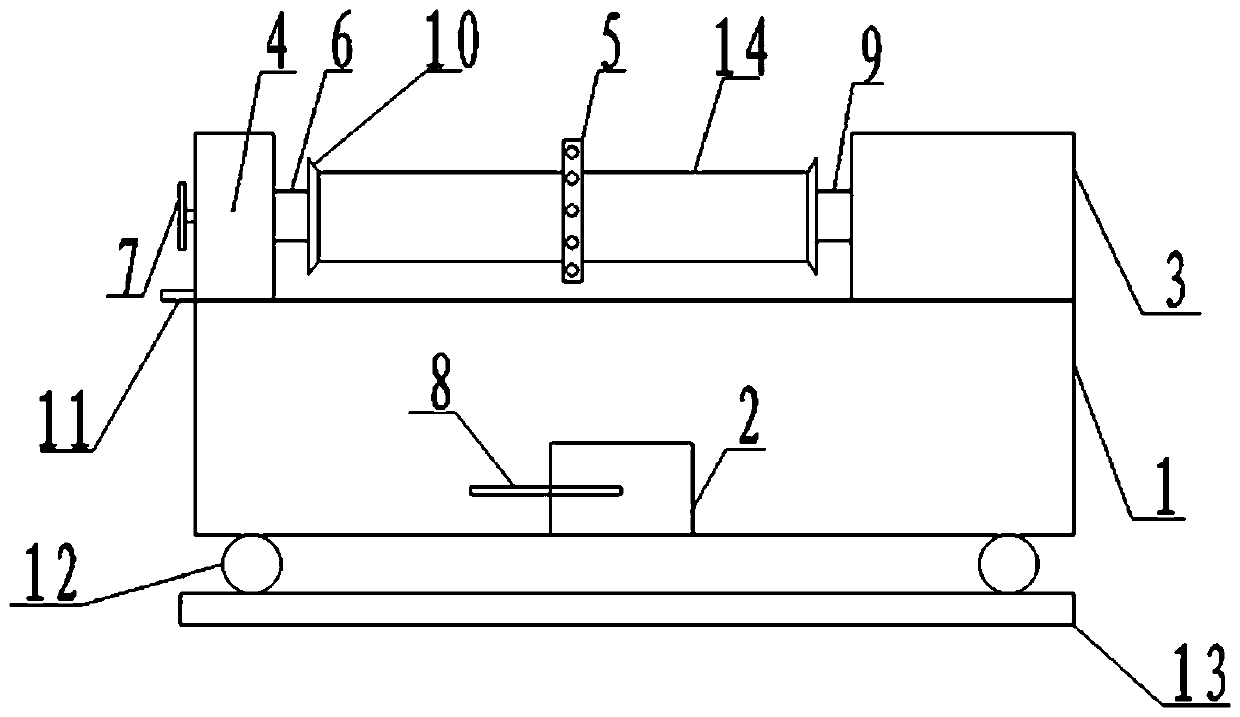

[0025] A device for repairing the cylinder barrel of an oil cylinder, including a frame 1, a reducer 2, a motor 3, a tailstock 4, an intermediate frequency heater and a copper ring 5, the reducer 2 is located at the bottom of the frame 1, and the motor 3 is located at one end of the frame 1 Platform, the tailstock 4 is located on the platform at the other end of the frame 1, where the tailstock 4 is provided with a top shaft I6 on one side, a handle I7 on the other side, a handle II8 on the reducer 2, and a motor 3 output shaft Top shaft II9, top shaft I6 and top shaft II9 are respectively provided with apexes 10, the platform of frame 1 is provided with drain pipe 11 on one side of tailstock 4, and the bottom of frame 1 is provided with traveling wheels 12 and traveling rails 13 .

[0026] The copper ring 5 is a copper tube with a diameter of 1.5 cm. The inner and outer su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com