Automatic honing device and machining method

A kind of honing and automatic technology, which is applied in the direction of grinding drive device, honing machine tool, grinding workpiece support, etc., can solve the problems of slow sales, low efficiency, increased workload of workers, etc., and achieve high processing efficiency, convenient replacement, and applicable wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

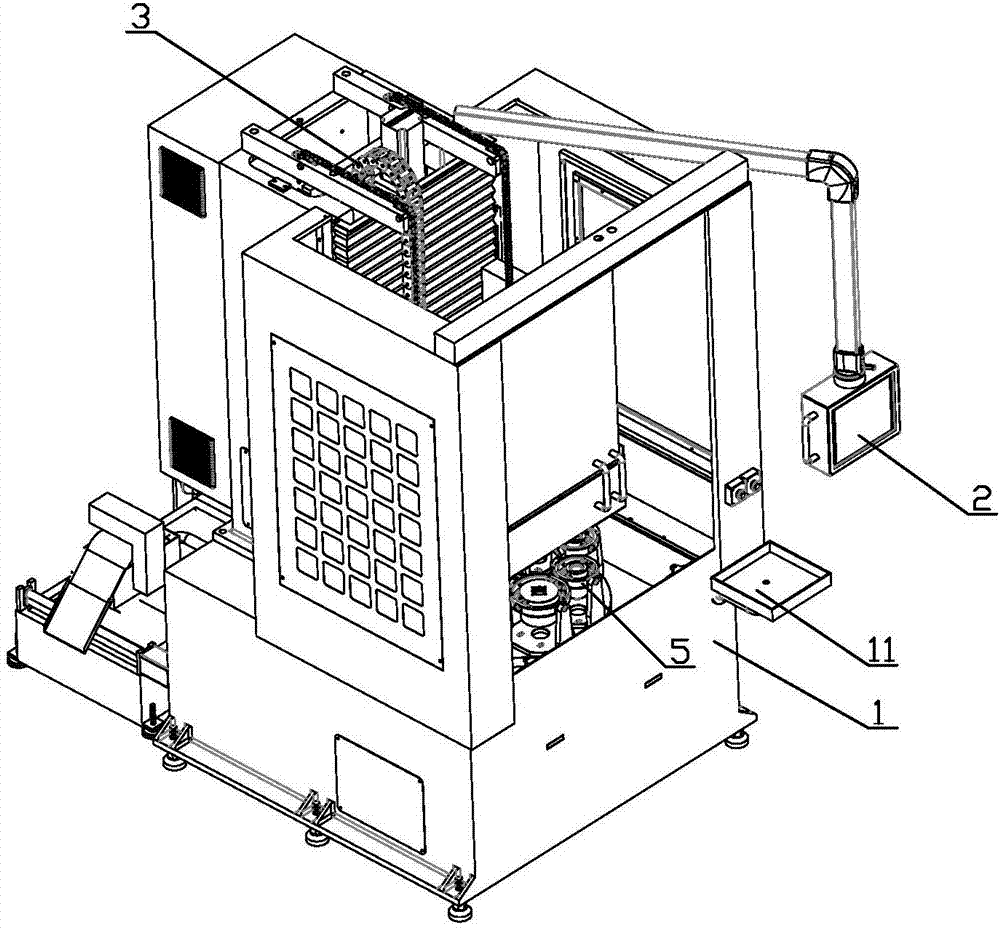

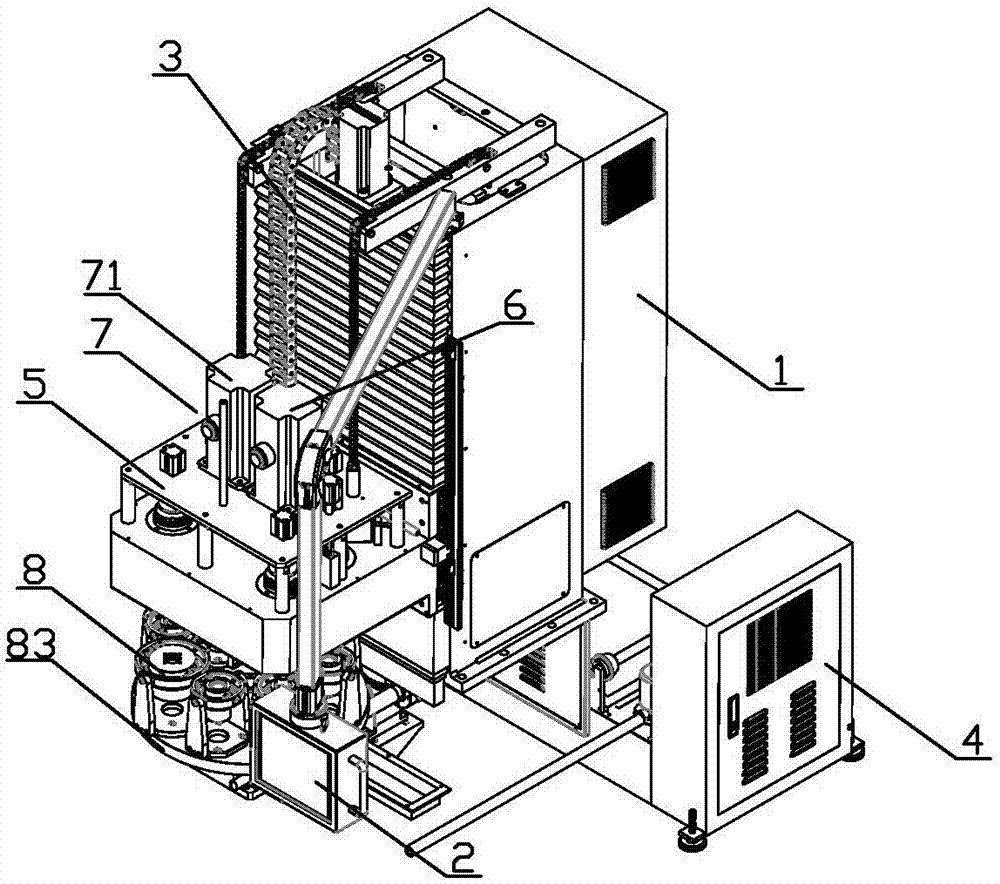

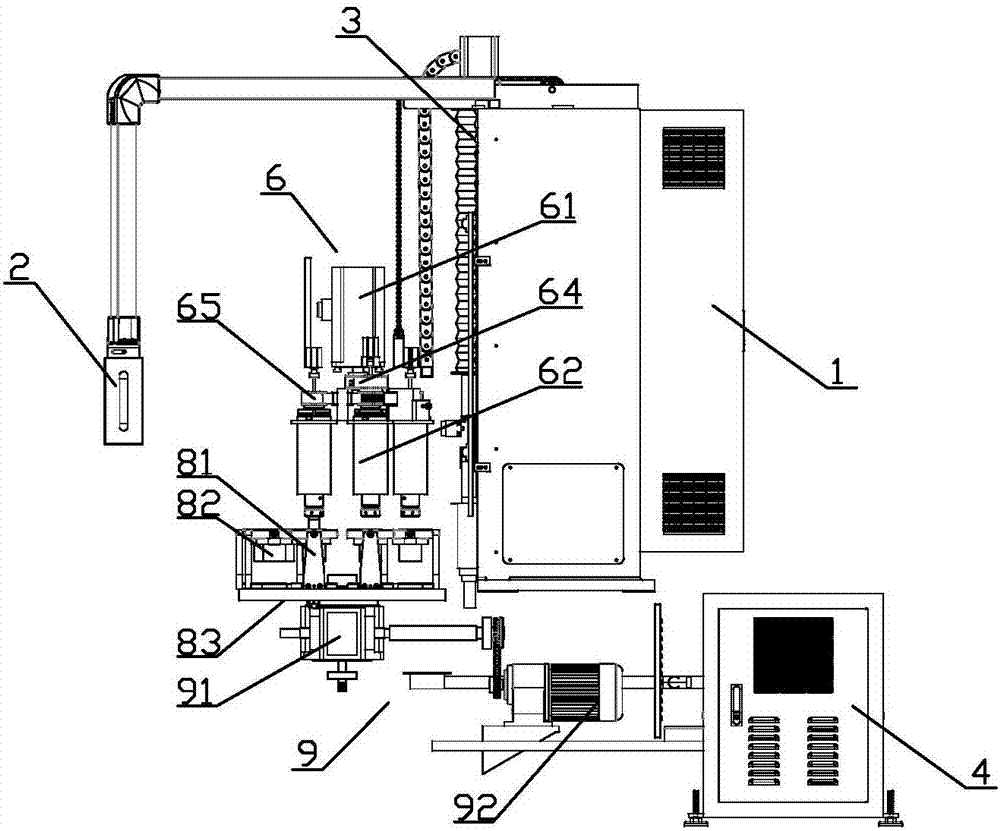

[0036] like figure 1 and figure 2 , an automatic honing device, comprising a body 1, a control cabinet 4 connected to the body 1, and a grinding device connected to the control cabinet 4, and also includes a touch panel 2 electrically connected to the control cabinet 4, the grinding The cutting device includes a lifting device 3, a fixed support plate 5, a first grinding assembly 6, a second grinding assembly 7, a tooling support 8 and a partition assembly 9; the fixed support plate 5 is connected to the chain of the lifting device 3 Above, the lifting device 3 drives the fixed support plate 5 up and down through precision ball screw transmission, and the first grinding assembly 6 and the second grinding assembly 7 are fixed on the fixed support plate 5; The tooling support 8 is fixed on the turntable 83, and the turntable 83 is connected with the partition assembly 9, and the partition assembly 9 is fixed on the body 1;

[0037] like image 3 , the first grinding assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com