Automatic control system for sewage treatment in sewage treatment plant

An automatic control, sewage treatment plant technology, applied in water treatment parameter control, water/sewage multi-stage treatment, biological water/sewage treatment, etc., can solve the problems of high maintenance cost and large amount of cable laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, by describing embodiment, the present invention will be further described:

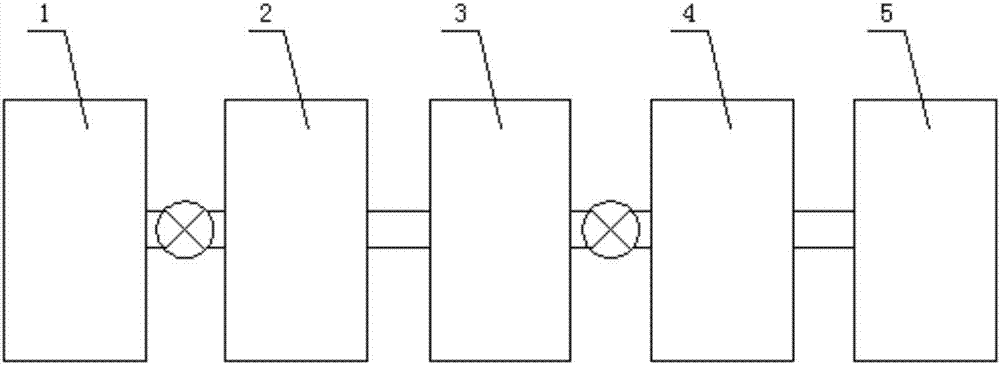

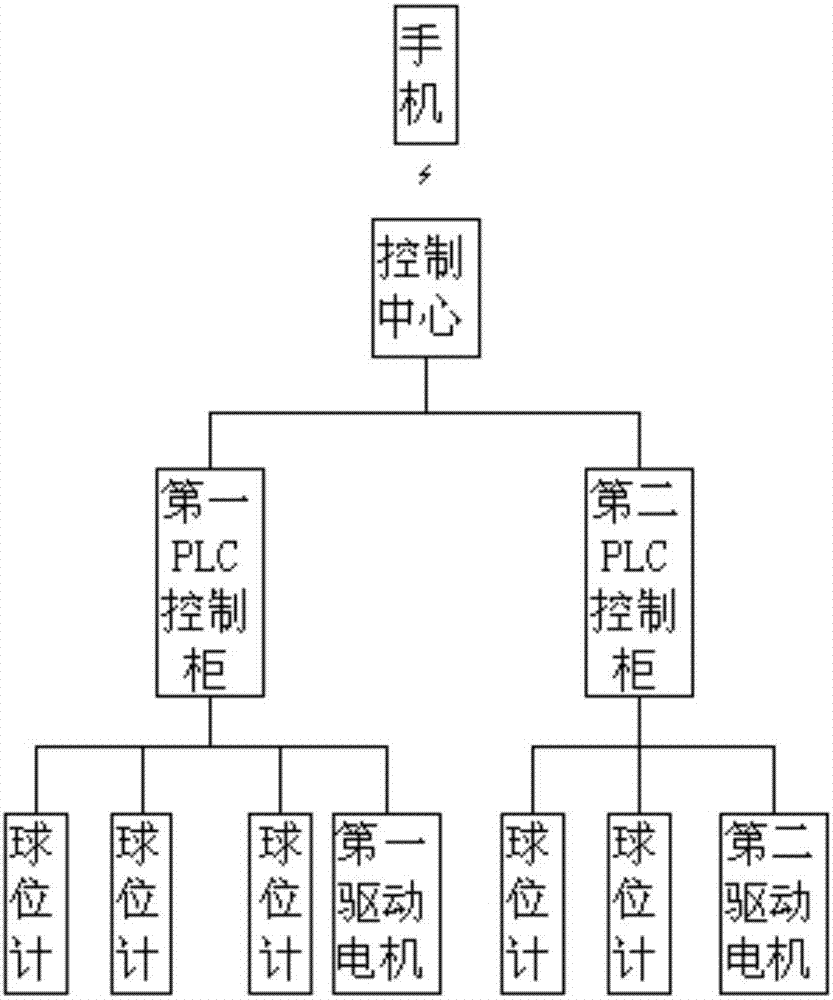

[0011] Such as figure 1 , 2 As shown, a kind of automatic control system for sewage treatment of the sewage treatment plant of the present invention comprises a sump 1, a reaction pool 2, a storage tank 3, a biochemical pool 4 and a submerged pool 5, and the sump 1 passes through the first water pump and the reaction The pool 2 is connected, the reaction pool 2 is connected with the water storage tank 3 through the water pipe, the water storage tank 3 is connected with the biochemical pool 4 through the second water pump, the biochemical pool 4 is connected with the sinking pool 5 through the water pipe, the sump 1, the reaction pool 2, the water storage tank 3. The biochemical pool 4 and the submerged pool 5 are respectively equipped with ball position gauges. The first water pump and the second water pump are respectively controlled by the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com