Multistage circulating-type sewage processing method

A sewage treatment method and cyclic technology, applied in the field of sewage treatment, can solve the problems of high cost of anaerobic reaction equipment, reduce the use effect of clear liquid, destroy anaerobic microorganisms, etc., achieve complete deodorization effect, reduce the amount of laying, promote Effects of Contact Response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

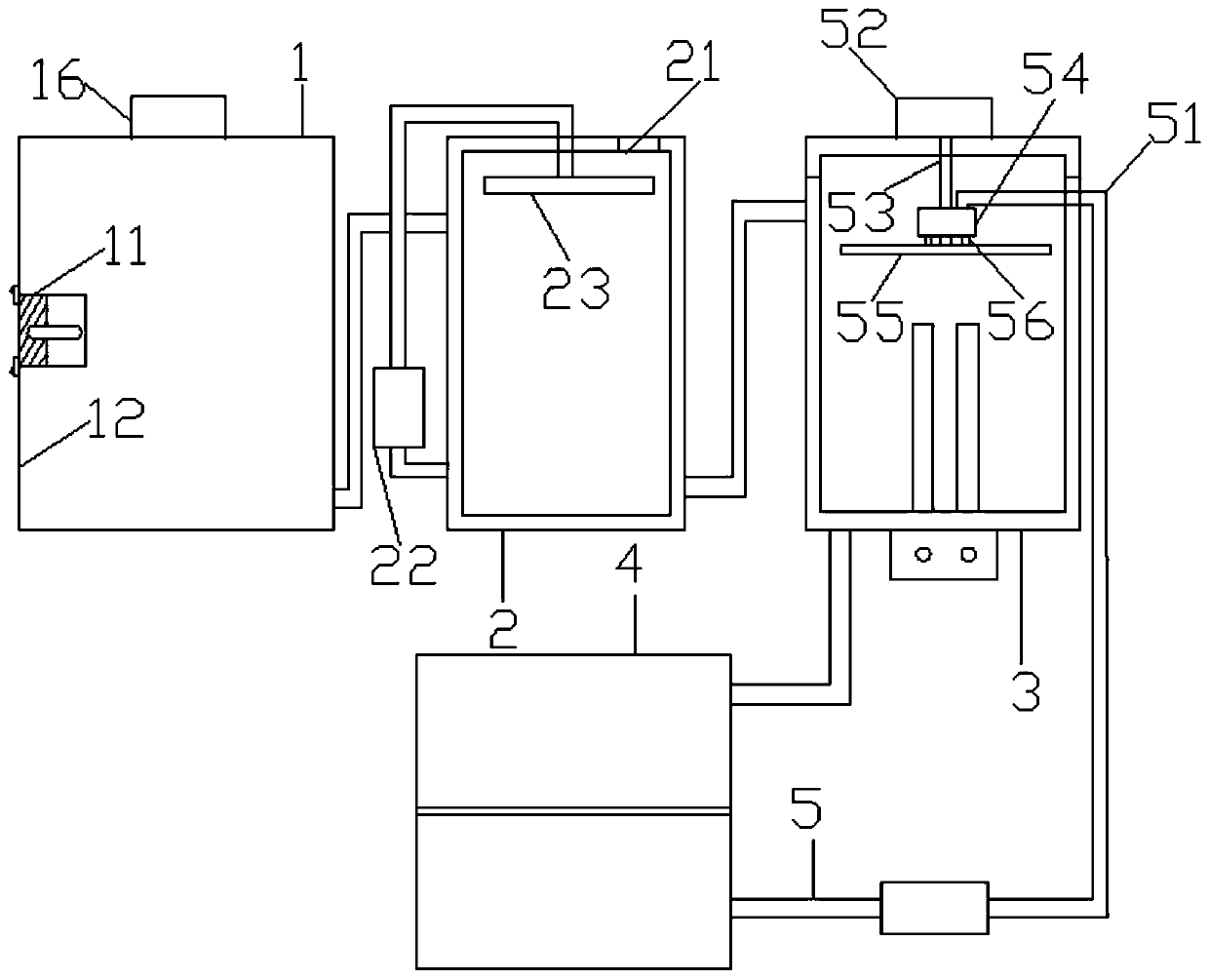

[0030] A multi-stage circulating sewage treatment method is characterized in that it comprises the following steps:

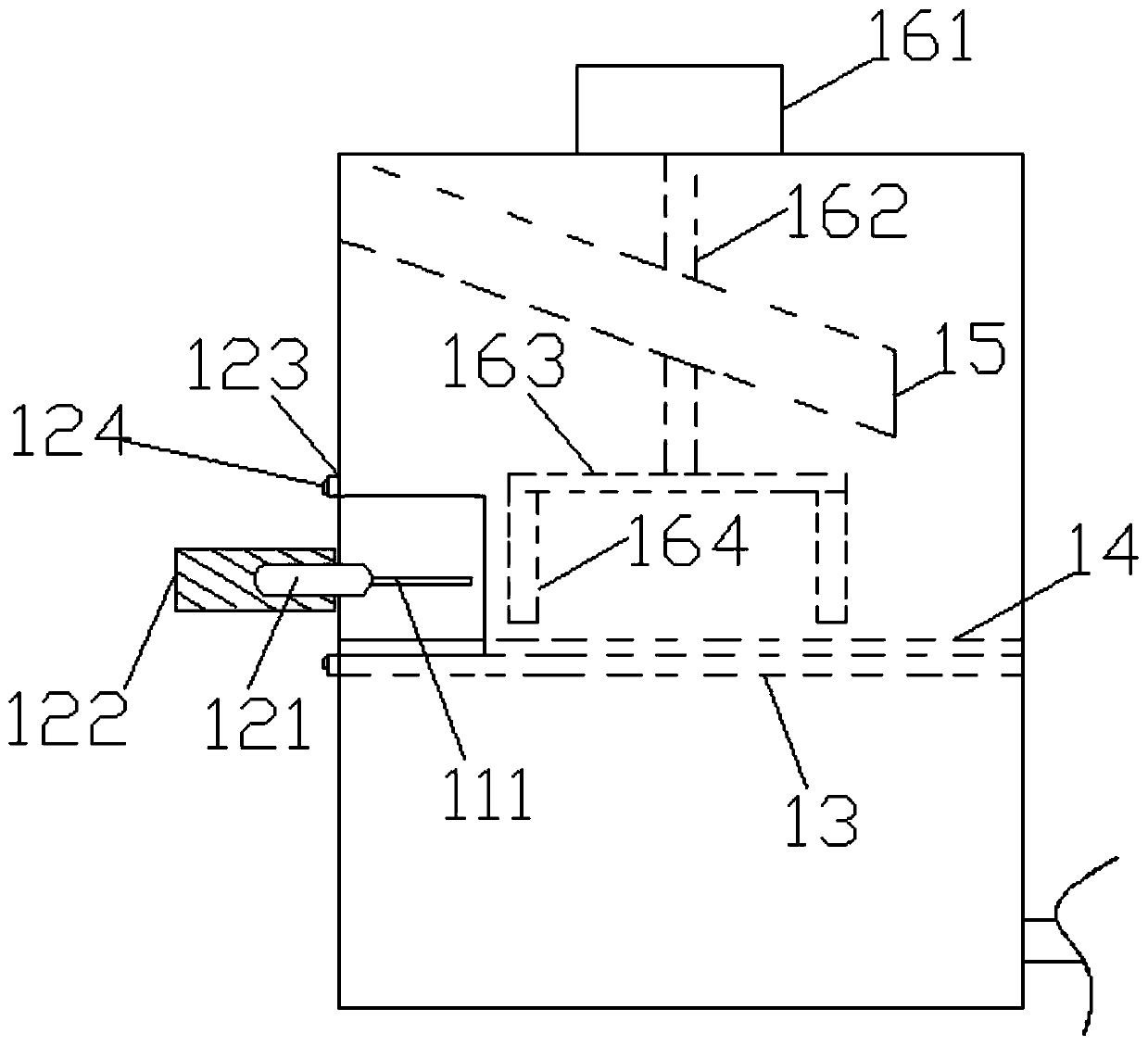

[0031] a) No. 1 treatment solution is obtained after being filtered in the pretreatment tank 1;

[0032] b) The deodorizing tank 2 adjusts the pH value of the No. 1 treatment solution to 6.8, and adds the Huangshan Maofeng extract from the dosing port 21, and the Huangshan Maofeng extract is extracted with 75% ethanol solution at 70°C for 12 hours, cooled, concentrated and dried. Get, Huangshan Maofeng extract and No. 1 treatment solution are added according to the ratio of 0.030g: 1L, and the circulation pump 22 transfers the liquid at the bottom of the deodorization tank 2 to the spray plate 23, and falls from the spray port, and the reaction time is 20min , the reaction temperature is 30°C to obtain No. 2 treatment solution;

[0033] c) No. 2 treatment solution is electrolyzed in electrolyzer 3 to obtain No. 3 treatment solution;

[0034] d) Separation tank ...

Embodiment 2

[0036] A multi-stage circulating sewage treatment method is characterized in that it comprises the following steps:

[0037] a) No. 1 treatment solution is obtained after being filtered in the pretreatment tank 1;

[0038] b) Deodorization tank 2 adjusts the pH value of the No. 1 treatment solution to 7.2, and adds Lu'an Guapian extract from the dosing port 21, and the Lu'an Guapian extract is extracted with 75% ethanol solution at 65° C. for 12 hours, cooled, concentrated and dried. Get, Lu'an Guapian extract and No. 1 treatment solution are added according to the ratio of 0.035g: 1L, and the circulation pump 22 transfers the liquid at the bottom of the deodorization tank 2 to the spray plate 23, and falls from the spray port, and the reaction time is 30min , the reaction temperature is 40°C to obtain No. 2 treatment solution;

[0039] c) No. 2 treatment solution is electrolyzed in electrolyzer 3 to obtain No. 3 treatment solution;

[0040] d) Separation tank 4 filters No. ...

Embodiment 3

[0042] A multi-stage circulating sewage treatment method is characterized in that it comprises the following steps:

[0043] a) No. 1 treatment solution is obtained after being filtered in the pretreatment tank 1;

[0044] b) Deodorizing tank 2 adjusts the pH value of the No. 1 treatment solution to 7.5, and adds the finch extract of Jintan from the dosing port 21, extracts the finch extract with 75% ethanol solution at 70°C for 12 hours, cools and concentrates It is prepared by drying, Jintan Quscus extract and No. 1 treatment solution are added at a ratio of 0.030g: 1L, and the circulation pump 22 transfers the liquid at the bottom of the deodorization tank 2 to the spray plate 23, and falls from the spray port to react. The time is 30min, the reaction temperature is 30°C, and the No. 2 treatment solution is obtained;

[0045] c) No. 2 treatment solution is electrolyzed in electrolyzer 3 to obtain No. 3 treatment solution;

[0046] d) Separation tank 4 filters No. 3 treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com