Thin film with granular handfeel, composite material and application

A composite material and film technology, applied in the field of composite materials, can solve the problems of contamination of medical equipment, patient wound infection, and inability to solve the problem of poor opening of Merbilliard frame movement, and achieves the effect of no additive migration, easy opening, and low friction coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

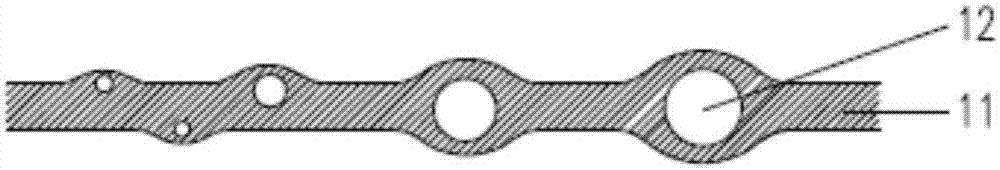

[0046] This embodiment provides a film with a grainy feel. The film has a single-layer structure and is prepared by a blown film process. The grammage of the film is 55g / m 2 .

[0047] The raw material formula of this film is: 68.74% metallocene linear low density polyethylene (melt index is 1g / 10min), 9.16% ultra-low density polyethylene (melt index is 4g / 10min), 13.74% high density polyethylene (The melt index is 1g / 10min), 1% ultra-high molecular weight polymer particles, 6.36% color masterbatch, 1% antistatic agent.

[0048] The performance of the film prepared from the above formula is compared with that of existing products on the market as shown in Table 1:

[0049] Table 1 is the result of performance comparison between Example 1 and existing products on the market

[0050] Test items

[0051] It can be seen that the coefficient of friction of the product of this embodiment is 37% lower than that of existing products on the market;

Embodiment 2

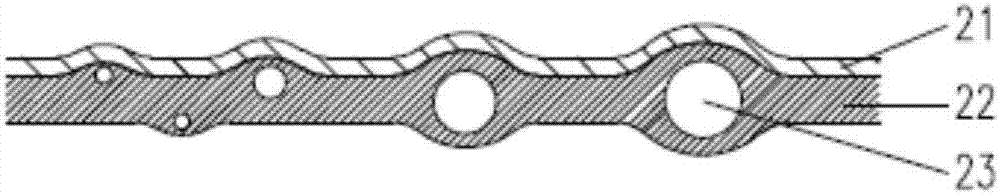

[0053] This embodiment provides a kind of film that has particle feel, and this film is the film of A / B / C three-layer structure, and layer thickness ratio is 20:60:20, and the ratio of ultra-high molecular weight polymer particles in the whole formula is 0.6 %, prepared by blown film process, the film weight is 55g / m 2 .

[0054] in:

[0055] The raw material formula of layer A is: 73.91% metallocene linear low density polyethylene, 9.85% ultra low density polyethylene, 14.78% high density polyethylene, 1.46% flame retardant.

[0056] The raw material formula of layer B is: 69.11% metallocene linear low density polyethylene, 8.62% ultra low density polyethylene, 13.27% high density polyethylene, 1% ultra high molecular weight polymer particles, 8.00% color masterbatch .

[0057] The raw material formula of the C layer is: 72.79% metallocene linear low density polyethylene, 9.71% ultra low density polyethylene, 14.56% high density polyethylene, 2.94% antistatic agent.

[00...

Embodiment 3

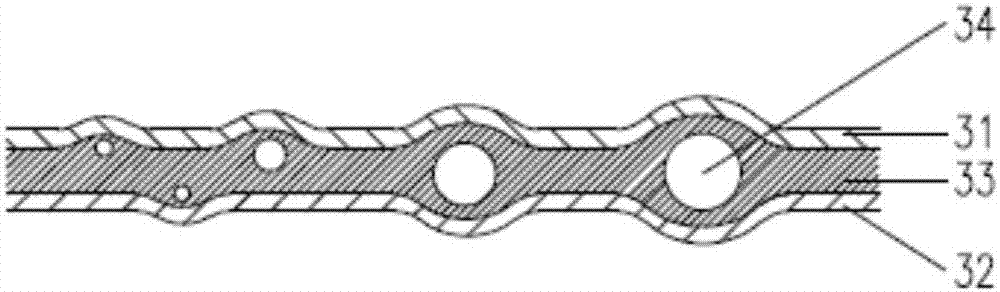

[0064] This embodiment provides a kind of film that has particle feel, and this film is the film of A / B / C three-layer structure, and layer thickness ratio is 20:60:20, and the ratio of ultra-high molecular weight polymer particles in the whole formula is 0.6 %, blown film process, the film weight is 55g / m 2 .

[0065] in:

[0066] The raw material formula of layer A is: 48.64% low density polyethylene, 48.64% linear low density polyethylene, 2.72% antistatic agent.

[0067] The raw material formula of layer B is: 45.50% low-density polyethylene, 45.50% linear low-density polyethylene, 1.00% ultra-high molecular weight polymer particles, and 8.00% color masterbatch.

[0068] The raw material formula of layer C is: 48.52% low-density polyethylene, 48.52% linear low-density polyethylene, 2.96% color masterbatch.

[0069] In this example, the melt index of low density polyethylene is 2g / 10min. The melt index of linear low density polyethylene is 2g / 10min.

[0070] The perform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com