Production technology of automobile drive support base

A production process and support seat technology, which is applied in the field of auto parts, can solve problems affecting the combination degree of the transmission device and the support seat, affecting the stability of the transmission device, wear and deformation of the support seat, etc., to achieve reduced friction coefficient, consistent performance, and improved The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

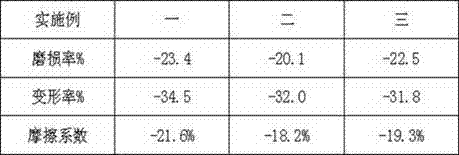

Examples

Embodiment 1

[0018] The production technology of a kind of automobile transmission supporting seat that the present invention proposes, comprises the following steps:

[0019] S1. Preparatory work: Cut the polyamide fiber, glass fiber and rock wool fiber respectively, control the length of the fiber below 5mm, and set aside;

[0020] S2. Preparation of support seat rubber: add polytetrafluoroethylene resin raw rubber, polyethersulfone resin raw rubber and epoxy resin raw rubber to the mixer in turn to heat and melt, and keep the melting temperature for 15 minutes, and then put the kneader The temperature is lowered by 30°C from the melting temperature, then add dispersant and curing agent, stir at a speed of 150r / min for 10min, then add molybdenum disulfide, carbon black and talcum powder into the mixer at a speed of 2g / min, continue Stir at a speed of 150r / min for 8 minutes, then increase the stirring speed to 250r / min, add glass fiber, rock wool fiber and polyamide fiber in turn, and mix...

Embodiment 2

[0024] The production technology of a kind of automobile transmission supporting seat that the present invention proposes, comprises the following steps:

[0025] S1. Preparatory work: Cut the polyamide fiber, glass fiber and rock wool fiber respectively, control the length of the fiber below 5mm, and set aside;

[0026] S2. Preparation of supporting seat rubber: add polytetrafluoroethylene resin raw rubber, polyethersulfone resin raw rubber and epoxy resin raw rubber to the mixer in turn to heat and melt, and keep the melting temperature for 20 minutes, and then put the kneader The temperature is lowered by 20°C from the melting temperature, then add dispersant and curing agent, stir at a speed of 150r / min for 5min, then add molybdenum disulfide, carbon black and talcum powder into the mixer at a speed of 2g / min, continue Stir at a speed of 200r / min for 5 minutes, then increase the stirring speed to 300r / min, add glass fiber, rock wool fiber and polyamide fiber in turn, and m...

Embodiment 3

[0030] The production technology of a kind of automobile transmission supporting seat that the present invention proposes, comprises the following steps:

[0031] S1. Preparatory work: Cut the polyamide fiber, glass fiber and rock wool fiber respectively, control the length of the fiber below 5mm, and set aside;

[0032] S2. Preparation of support seat rubber: add polytetrafluoroethylene resin raw rubber, polyethersulfone resin raw rubber and epoxy resin raw rubber to the mixer in turn to heat and melt, and keep the melting temperature for 15 minutes, and then put the kneader The temperature is lowered by 30°C from the melting temperature, then add dispersant and curing agent, stir at a speed of 100r / min for 10min, then add molybdenum disulfide, carbon black and talcum powder into the mixer at a speed of 2g / min, continue Stir at a speed of 200r / min for 5 minutes, then increase the stirring speed to 300r / min, add glass fiber, rock wool fiber and polyamide fiber in turn, and mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com