Clear polyurethane seal primer and preparation method thereof

A technology of clear primer and polyurethane, which is applied in the field of coatings, can solve the problems of high cost, unsatisfactory filling performance of polyurethane sealed clear primer, multiple constructions, etc., and achieve the effect of low cost, advanced practicability and saving paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] On the other hand, the embodiment of the present invention also provides a kind of preparation method of polyurethane sealing clear primer, comprises the steps:

[0032] S01: Weigh the raw materials of each component according to the components contained in the above-mentioned polyurethane sealing clear primer and their contents;

[0033] S02: Adding the defoamer to the above alkyd resin solution to perform the first mixing treatment to obtain the first mixture;

[0034] S03: adding polypropylene wax powder to the above-mentioned first mixture to perform a second mixture treatment to obtain a second mixture;

[0035] S04: adding xylene and the first butyl acetate to the above-mentioned second mixture to carry out the third mixture treatment to obtain component A;

[0036] S05: Perform fourth mixing treatment on the aromatic isocyanate adduct and the second butyl acetate to obtain component B.

[0037] The preparation method of the polyurethane sealing clear primer pro...

Embodiment 1

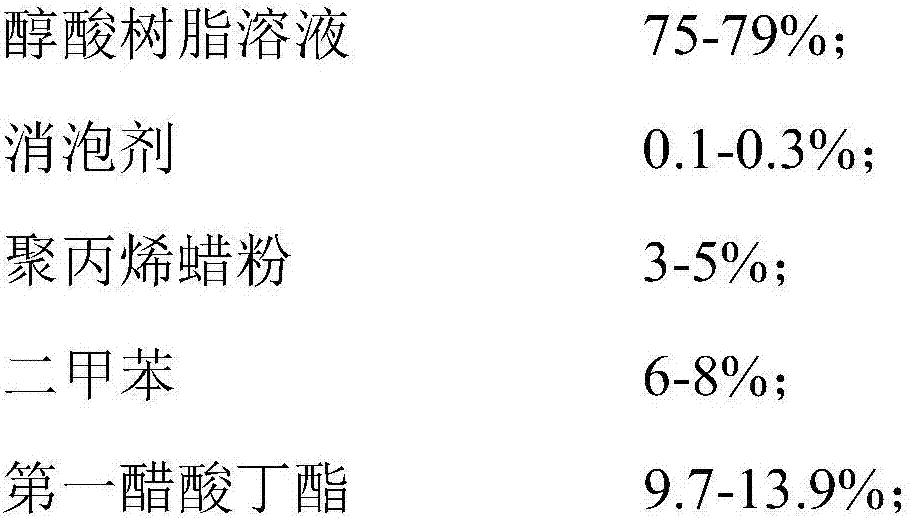

[0041] A polyurethane sealing clear primer, comprising A component and B component, based on the total mass of the A component as 100%, it includes the following components in mass percentage:

[0042]

[0043] Based on the total mass of the B component as 100%, it includes the following components in mass percentages:

[0044] Butyl acetate 25%;

[0045] Aromatic isocyanate adduct 75%;

[0046] Wherein, A component: B component=2:1 (mass ratio).

[0047] The preparation method of above-mentioned polyurethane sealing clear primer comprises the steps:

[0048] S11: Weigh the raw materials of each component according to the components contained in the above-mentioned polyurethane sealing clear primer and their contents.

[0049] S12: adding the defoamer to the alkyd resin solution for the first mixing treatment to obtain the first mixture; wherein, the first mixing treatment process is: 60-80rpm / min, stirring for 10-20min.

[0050] S13: Adding polypropylene wax powder to ...

Embodiment 2

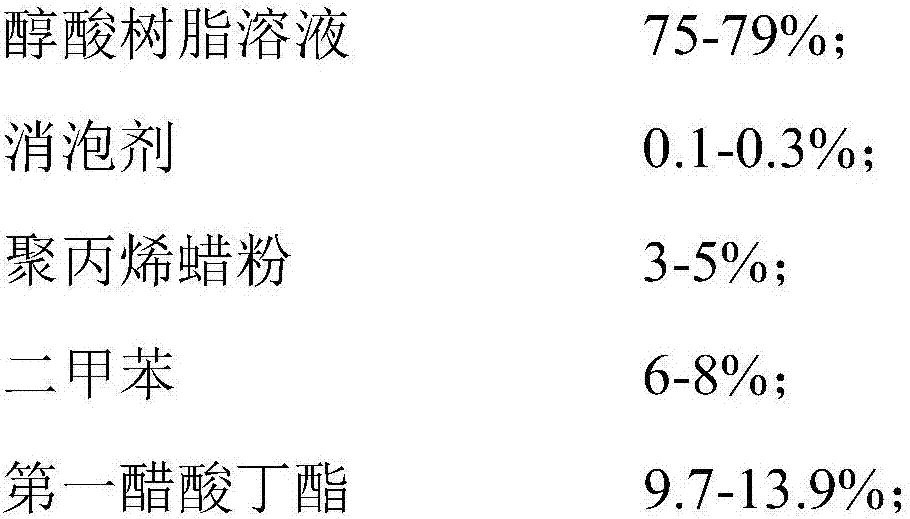

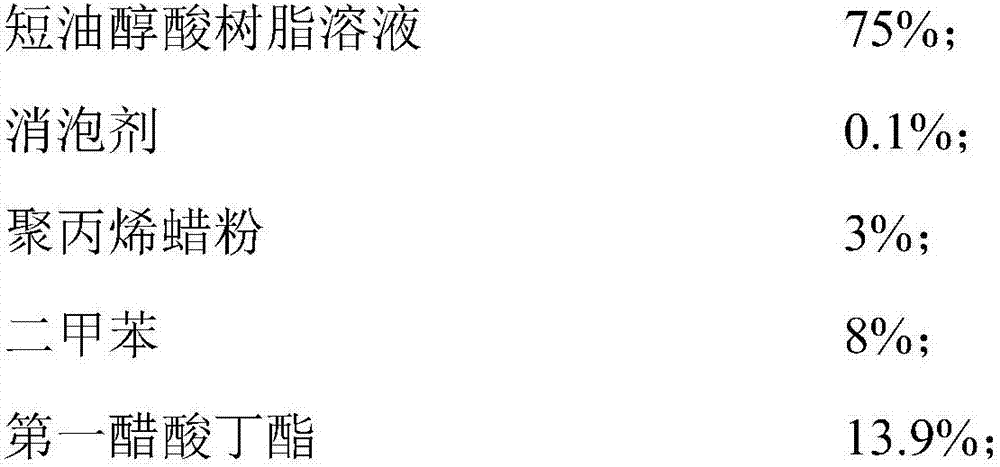

[0055] A polyurethane sealing clear primer, comprising A component and B component, based on the total mass of the A component as 100%, it includes the following components in mass percentage:

[0056]

[0057]

[0058] Based on the total mass of the B component as 100%, it includes the following components in mass percentages:

[0059] Butyl acetate 25%;

[0060] Aromatic isocyanate adduct 75%;

[0061] Wherein, A component: B component=2:1 (mass ratio).

[0062] The preparation method of above-mentioned polyurethane sealing clear primer is the same as embodiment 1.

[0063] The above formula is made into a polyurethane sealing clear primer according to the preparation method provided by the embodiments of the present invention, and after being prepared by A component: B component=2:1 (mass ratio), add an appropriate amount of diluent on the polished white Carry out construction on the embryonic wood, and then carry out construction according to the normal closed con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com