A kind of UV-curable adhesive doped with nano-titanium dioxide and its preparation method

A technology of nano-titanium dioxide and ultraviolet light, which is applied in the direction of adhesives, adhesive additives, adhesive types, etc., to achieve the effects of reducing costs, high tensile strength, and reducing the chance of compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

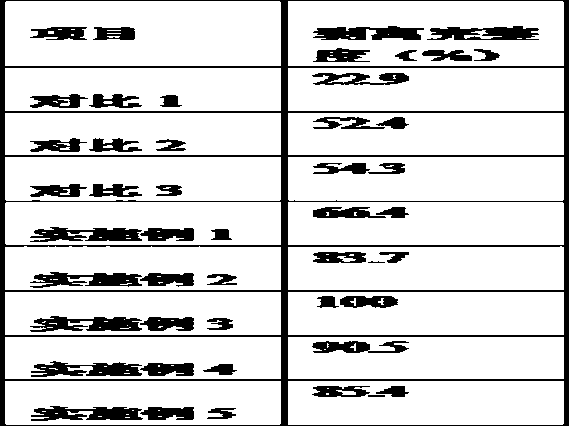

Examples

Embodiment 1

[0049] It consists of the following raw materials in parts by weight: 40 parts of self-made bifunctional urethane acrylate prepolymer, 10 parts of multifunctional urethane acrylate prepolymer, 8 parts of polyester acrylate prepolymer, and 12 parts of reactive amine complexing agent , 20 parts of acrylate reactive diluent, 2 parts of leveling wetting agent, 2 parts of photoinitiator, 1 part of titanium dioxide nanopowder, 5 parts of fumed silica;

[0050] The self-made bifunctional polyurethane acrylate prepolymer is carried out according to the following steps:

[0051] Dehydrate the polyether diol at a temperature of 110°C and a pressure of -0.098MPa for 1.5 hours; add diisocyanate at a temperature of 60°C and a pressure of -0.098, stir for 0.6h, add a catalyst, and React at 75°C and pressure -0.098MPa for 2h; Add polymerization inhibitor and hydroxyl-containing acrylate in sequence and stir for 2h at temperature 70°C and pressure -0.098MPa, take samples every 30min with infr...

Embodiment 2

[0062] It consists of the following raw materials in parts by weight: 40 parts of self-made bifunctional urethane acrylate prepolymer, 10 parts of multifunctional urethane acrylate prepolymer, 8 parts of polyester acrylate prepolymer, and 12 parts of reactive amine complexing agent , 20 parts of acrylate reactive diluent, 2 parts of leveling wetting agent, 2 parts of photoinitiator, 1.5 parts of titanium dioxide nanopowder, 4.5 parts of fumed silica;

[0063] The self-made bifunctional polyurethane acrylate prepolymer is carried out according to the following steps:

[0064] Dehydrate the polyether diol at a temperature of 110°C and a pressure of -0.098MPa for 1.5 hours; add diisocyanate at a temperature of 60°C and a pressure of -0.098, stir for 0.6h, add a catalyst, and React at 75°C and pressure -0.098MPa for 2h; Add polymerization inhibitor and hydroxyl-containing acrylate in sequence and stir for 2h at temperature 70°C and pressure -0.098MPa, take samples every 30min with...

Embodiment 3

[0075] It consists of the following raw materials in parts by weight: 40 parts of self-made bifunctional urethane acrylate prepolymer, 10 parts of multifunctional urethane acrylate prepolymer, 8 parts of polyester acrylate prepolymer, and 12 parts of reactive amine complexing agent , 20 parts of acrylate reactive diluent, 2 parts of leveling wetting agent, 2 parts of photoinitiator, 2 parts of titanium dioxide nanopowder, 4 parts of fumed silica;

[0076] The self-made bifunctional polyurethane acrylate prepolymer is carried out according to the following steps:

[0077] Dehydrate the polyether diol at a temperature of 110°C and a pressure of -0.098MPa for 1.5 hours; add diisocyanate at a temperature of 60°C and a pressure of -0.098, stir for 0.6h, add a catalyst, and React at 75°C and pressure -0.098MPa for 2h; Add polymerization inhibitor and hydroxyl-containing acrylate in sequence and stir for 2h at temperature 70°C and pressure -0.098MPa, take samples every 30min with inf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com