Preparation method of high-strength and high-tenacity stainless steel

A high-strength, high-toughness, stainless steel technology, applied in the field of metal processing, can solve problems such as the inability to achieve industrialized production, and achieve the effects of simple shot peening and annealing processes, good economic benefits, and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing:

[0038] The present invention comprises the following steps:

[0039] (1) get thickness 1.5mm, size is 304 stainless steel plates of 50X50mm;

[0040] (2) Put the 50x50mm plate into a high-temperature electric furnace for solution treatment at 1050°C for 30 minutes, then rapidly cool to room temperature and then pickle for 30 minutes;

[0041] (3) Double-sided alternate shot peening method and 0.2MPa / 1min+0.5MPa / 8min composite shot peening process are adopted, the stainless steel shot peening diameter is 0.4mm, the distance from the nozzle to the sample surface is 80-100mm, and the spray angle is 90° ;

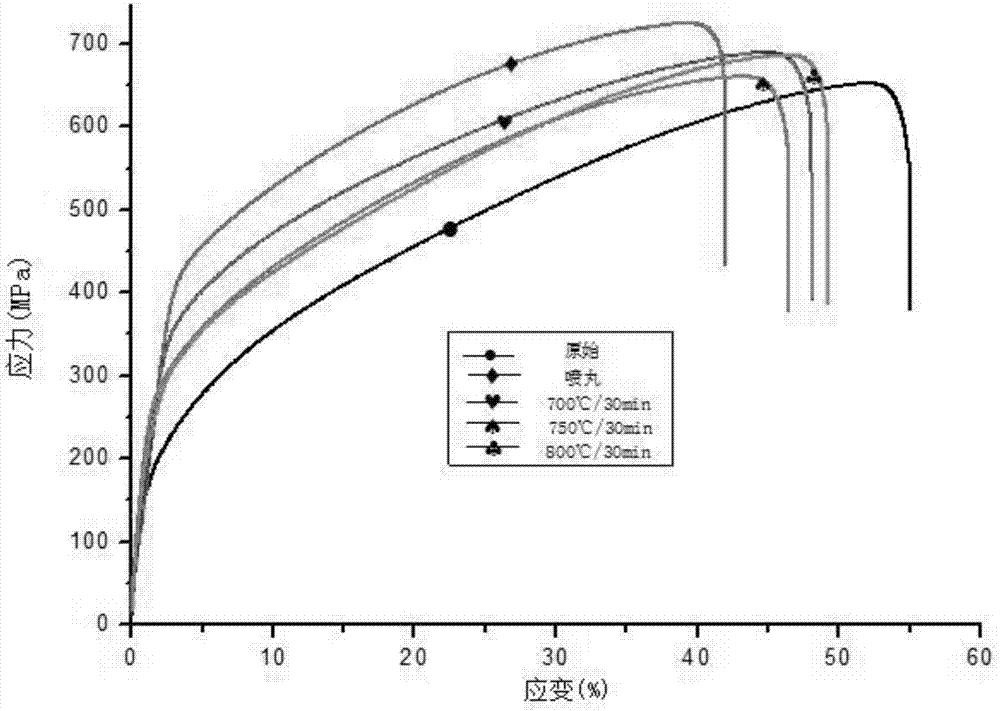

[0042] (4) Anneal the steel plate after shot peening at 700°C and 30min,

[0043] (5) The samples after shot blasting were washed with absolute ethanol and dried.

[0044] The pickling treatment in the step (2) specifically includes: soaking in stainless steel pickling p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com