Construction technology of insulation heat preservation layers of deep cooling pipeline connecting equipment

A technology for connecting equipment and construction technology, which is applied in pipeline protection, thermal insulation, mechanical equipment, etc., can solve the problems of thermal insulation performance impact and thermal insulation requirements without paying too much attention, achieve good bonding, reduce cumbersome operation, and facilitate construction Quick and easy results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with specific embodiments of the present invention.

[0021] The construction process of the insulation layer of a cryogenic pipeline connection equipment disclosed by the present invention comprises the following steps:

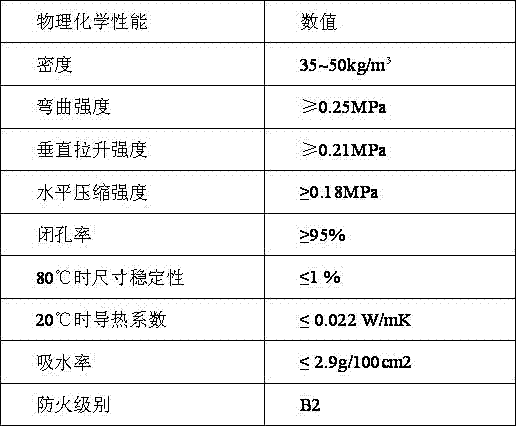

[0022] a. Determine the size of the prefabricated insulation block according to the size of the equipment and the insulation thickness requirements;

[0023] b. Clean the surface of the equipment to ensure that there is no oil, dust and water stains on the surface of the equipment, and then use a protective film to protect the valves, pressure gauges, and consoles to prevent pollution from foam splashes;

[0024] c. Draw the installation line of the prefabricated block on the surface of the equipment according to the circumference of 60°. The installation line is arranged longitudinally on the surface of the equipment, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com