A rolling bearing compound fault extraction method and system

A composite fault and rolling bearing technology, which is applied in the testing of machine/structural components, testing of mechanical components, instruments, etc., can solve problems such as misjudgment and missed judgment, incomplete evaluation of mechanical equipment operation, and incomplete extraction of fault components, etc. To achieve the effect of avoiding missed diagnosis and misdiagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

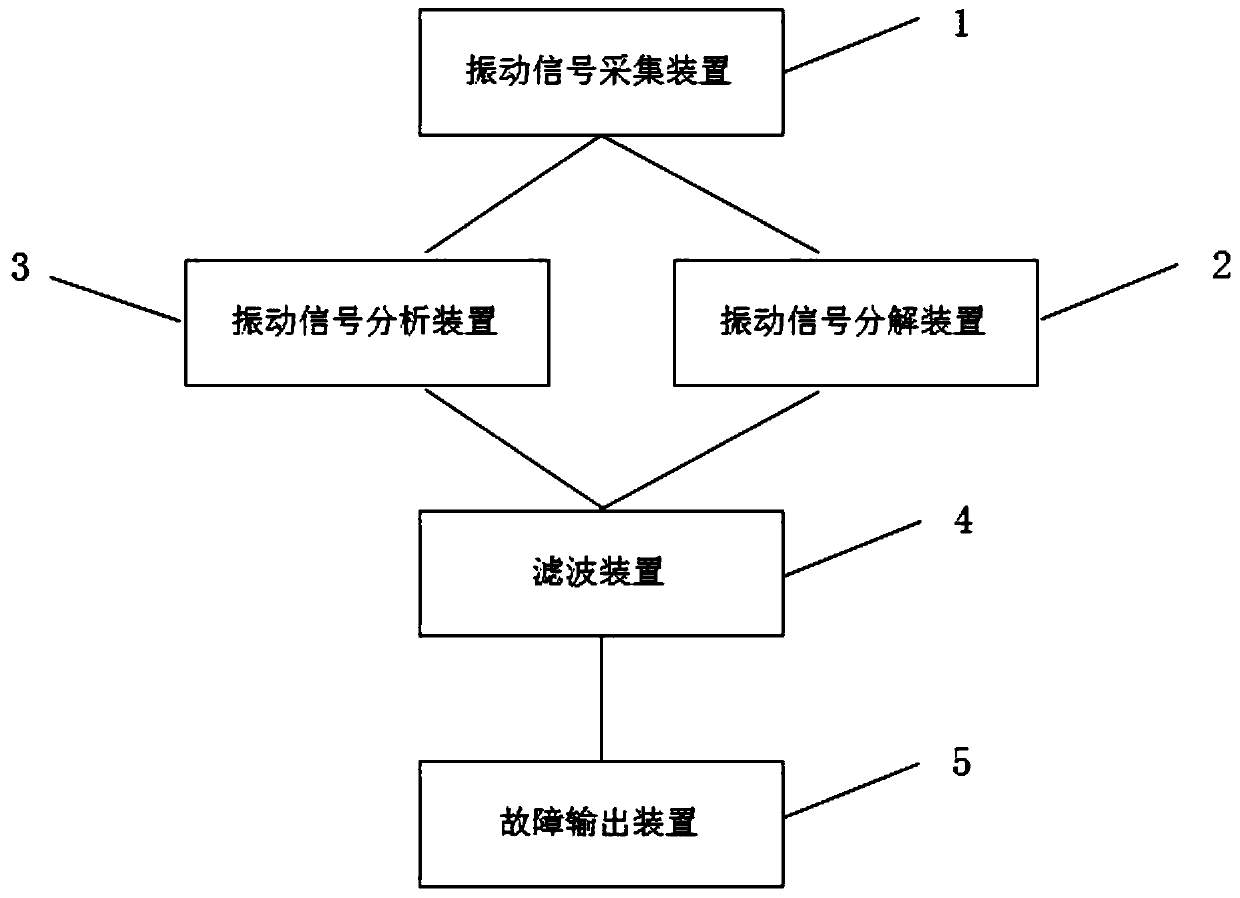

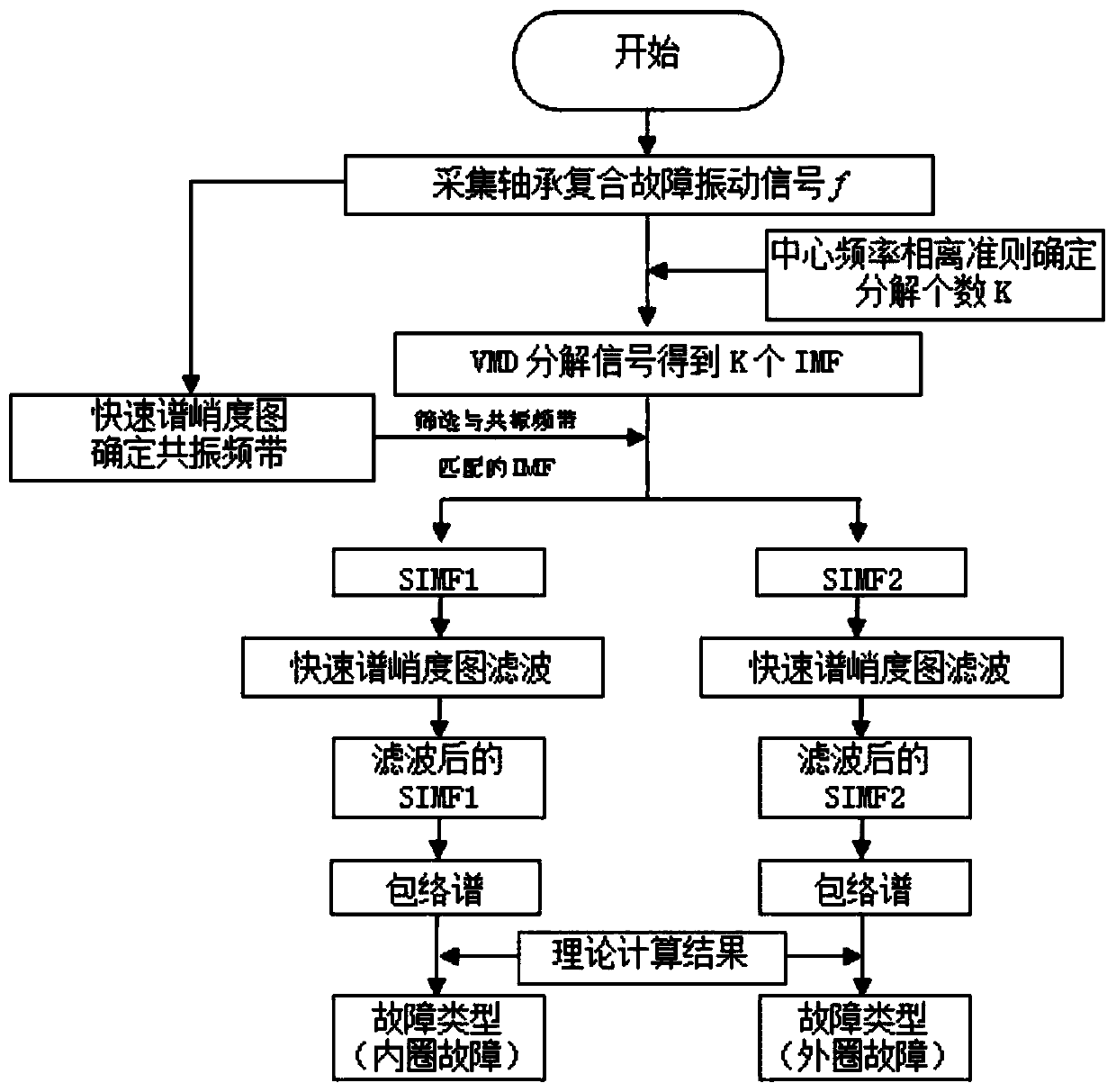

[0038] A rolling bearing compound fault extraction system, comprising a vibration signal acquisition device (1), a vibration signal decomposition device (2), a vibration signal analysis device (3), a filtering device (4), a fault output device (5); a vibration signal acquisition device (1) is a vibration acceleration sensor, which is used to obtain the vibration signal of the bearing composite fault and transmit it to the vibration signal decomposition device (2) and the vibration signal analysis device (3). Partial mode decomposition is used to increase the dimension and reduce noise, and decompose it into K IMF components. The vibration signal analysis device (3) is used to analyze the vibration signal through the fast spectral kurtosis diagram to obtain J resonance frequency bands, where J is less than or equal to K; the filtering device (4) is used to filter the IMF component output by the vibration signal decomposition device (2), and the fault output device (5) is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com