BPS array substrate and making method thereof

A technology of an array substrate and a manufacturing method, which are applied in the field of BPS type array substrate and its manufacture, can solve the problems of poor film thickness uniformity, incomplete cross-linking reaction, insufficient UV light dose, etc., so as to achieve low production cost and improve product competitiveness. , easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

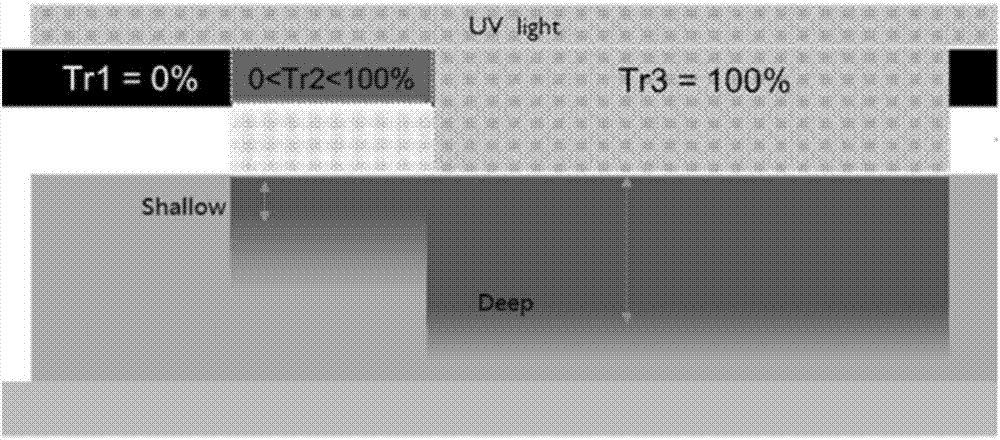

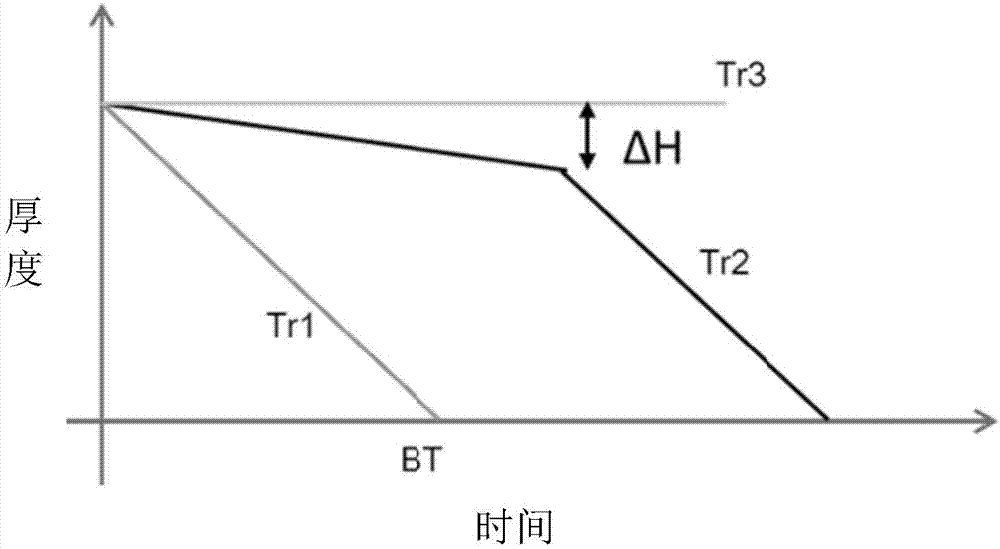

[0045] The idea of the present invention is to combine BPS technology with COA (Color Filter on Array) technology, not only make black matrix 83, main spacer 81, and auxiliary spacer 82 on the array substrate, but also color light The resist layer 40 is fabricated on the array substrate, and the height difference between the main spacer 81 and the black matrix 83 is realized by using the height of the color resist unit 41 , and the light transmittance of the mask plate 70 is controlled by using the thickness of the color resist unit 41 To realize the height difference between the sub spacers 82 and the black matrix 83 .

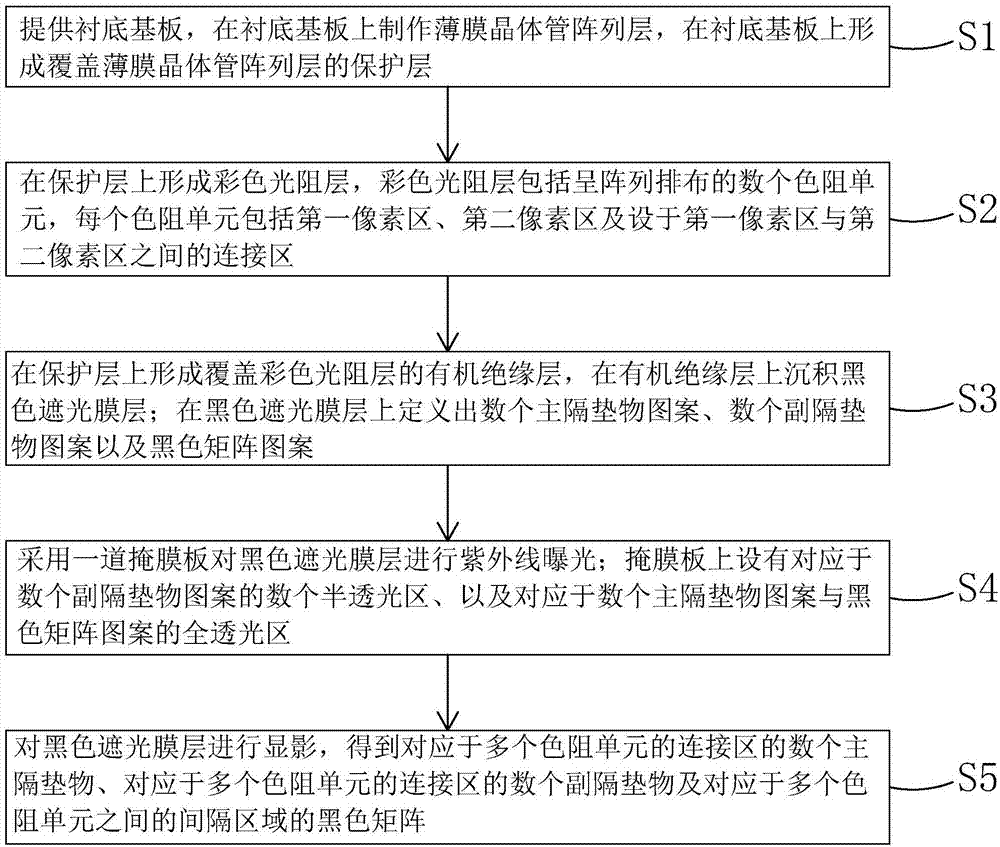

[0046] see image 3 , the present invention provides a method for manufacturing a BPS type array substrate, comprising t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com