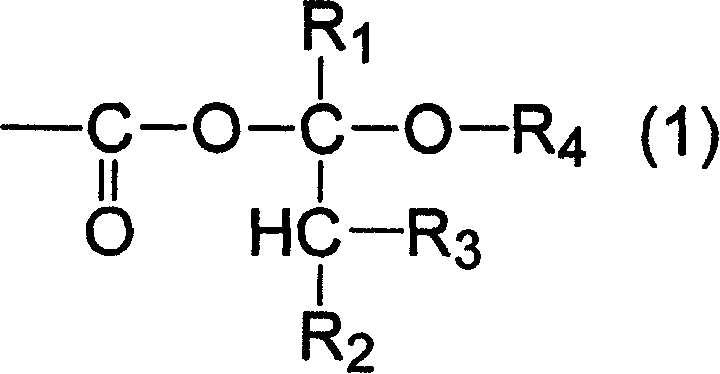

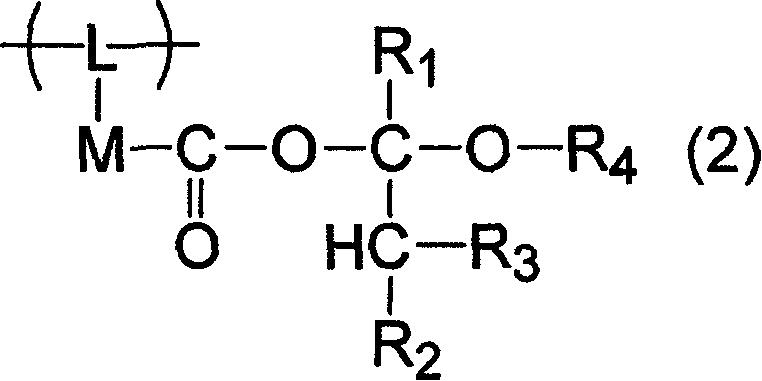

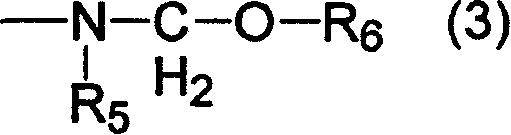

Composition for forming lower layer film for lithography comprising compound having protected carboxyl group

A composition and compound technology, applied in the direction of image communication, electrical components, etc., can solve problems such as storage stability, and achieve the effects of high filling, excellent storage stability and good precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0192]

[0193] Dissolve 10 g of formula (57) of 1-ethoxyethyl methacrylate (Honshu Chemical Industry Co., Ltd. product) and 9 g of glycidyl methacrylate in 76 g of propylene glycol monomethyl ether acetate, and add to the solution After flowing nitrogen gas for 30 minutes, the temperature was raised to 70°C. While maintaining the reaction solution at 70° C., 0.38 g of azobisisobutyronitrile and 0.38 g of 1-dodecanethiol were added. After stirring at 70° C. for 8 hours under a nitrogen atmosphere, 0.1 g of 4-methoxyphenol was added to obtain a solution containing a copolymer of 1-ethoxyethyl methacrylate and glycidyl methacrylate. GPC analysis of the obtained polymer revealed that the number average molecular weight Mn was 7600, and the weight average molecular weight (standard polystyrene correction) Mw was 23000.

Synthetic example 2

[0195] Dissolve 10 g of 1-ethoxyethyl methacrylate (manufactured by Honshu Chemical Industry Co., Ltd.) of formula (57), 9 g of glycidyl methacrylate, and 12.7 g of methyl methacrylate in 126.6 g of propylene glycol monomethyl In ether acetate, nitrogen gas was passed through the solution for 30 minutes, and then the temperature was raised to 70°C. While maintaining the reaction solution at 70° C., 0.63 g of azobisisobutyronitrile and 0.63 g of 1-dodecanethiol were added. Under a nitrogen atmosphere, after stirring at 70°C for 8 hours, 0.1 g of 4-methoxyphenol was added to obtain a compound containing 1-ethoxyethyl methacrylate, glycidyl methacrylate and methyl methacrylate. Copolymer solution. GPC analysis of the obtained polymer revealed that the number average molecular weight Mn was 5,500, and the weight average molecular weight (standard polystyrene correction) Mw was 12,000.

Synthetic example 3

[0197]

[0198] Dissolve 15 g of 1-cyclohexyloxyethyl methacrylate (manufactured by Honshu Chemical Industry Co., Ltd.) of formula (58) and 10 g of glycidyl methacrylate in 38.0 g of butyl acetate, and flow nitrogen into the solution After 30 minutes, the temperature was raised to 70°C. While maintaining the reaction solution at 70° C., 0.25 g of azobisisobutyronitrile and 0.25 g of 1-dodecanethiol were added. After stirring at 70° C. for 8 hours under a nitrogen atmosphere, 0.1 g of 4-methoxyphenol was added to obtain a solution containing a copolymer of 1-cyclohexyloxyethyl methacrylate and glycidyl methacrylate. GPC analysis of the obtained polymer revealed that the number average molecular weight Mn was 9,000, and the weight average molecular weight (standard polystyrene correction) Mw was 50,000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com