Semi-automatic battery string defect detection equipment and detection method

A defect detection, semi-automatic technology, applied in photovoltaic power generation, electrical components, photovoltaic system monitoring, etc., can solve problems such as increased maintenance costs, image distortion misjudgment rate, waste of manpower and material resources, increased risks, etc., to improve cumbersome and Effects of waste, adding compatible functions, and reducing the risk of fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

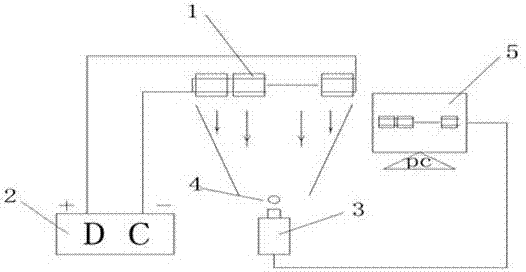

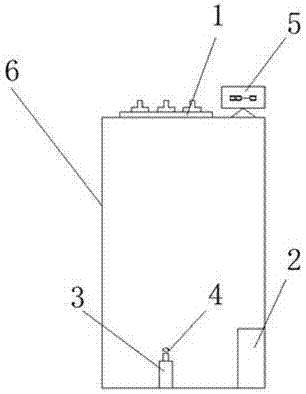

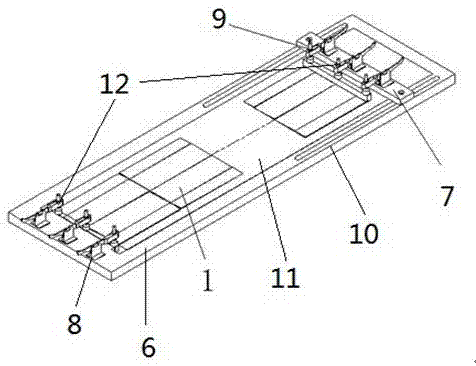

[0029] The technical solution of the present invention is to design a semi-automatic battery string defect detection equipment, including a power supply 2, a detection frame 6, an EL detector and a PC terminal 5. The detection frame 6 is connected to the power source 2 through a wire, and the detection frame 6 A number of pressure blocks A are equidistantly arranged at one end. The detection frame 6 is provided with a battery string placement surface 11, the battery string placement surface 11 is transparent, and the detection frame 6 is provided with an EL detector. The detector is provided with a detection head 3, the detection head 3 is provided with a filter 4, and the end of the EL detector is connected to the PC terminal 5. In this way, the addition of the filter 4 can solve the problem that the EL test must be completed in a dark room; the elimination of the reflector can shorten the light transmission path, avoid the misjudgment rate caused by image distortion and reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com