Oil-water separation device for oil-containing sewage

An oil-water separation device and oil-water separation technology, which are applied in the directions of grease/oily substance/float removal device, liquid separation, separation method, etc., can solve the problems of blurred oil-water separation interface, poor oil-water separation accuracy, low processing efficiency, etc. The effect of reducing energy consumption, reducing energy consumption, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

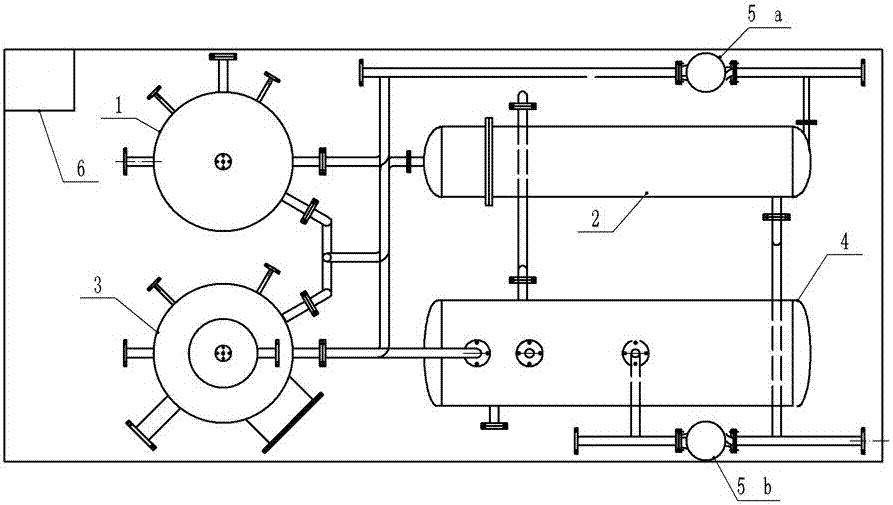

[0017] like figure 1 Shown is a schematic structural diagram of an oil-water separation device for oily sewage, including a PLC control system 6, and also includes a preheating tank 1, a heat exchanger 2, an oil-water separation and oil collection device 3, and a hot water storage tank 4. The above-mentioned PLC control system 6 is simultaneously connected with the valves at the water inlet of the preheating tank 1, the heat exchanger 2, the oil-water separation and oil collection device 3, and the hot water storage tank 4, the valves at the sewage outlet, and the valves at the water outlet. Electrically connected, the heat exchanger 2 is provided with a temperature measuring device and a heating device, and the temperature measuring device and the heating device are electrically connected to the PLC control system 6 at the same time. The oil-water separation and oil collection device 3 is provided with an electric heater and an aeration system, and the electric heater and aer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com