Building interior wall heat retaining board and manufacturing method thereof

A technology for building interior and thermal insulation boards, which is applied in thermal insulation, building components, flat products, etc., can solve the problems of great harm to the human body, harm to the human body, and endanger human health, etc., and achieves low production cost, reduction of industrial energy consumption, and avoidance of pollution. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

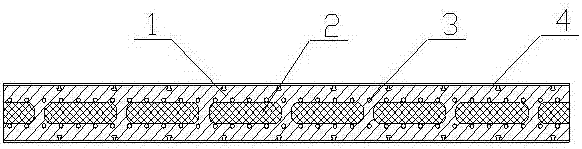

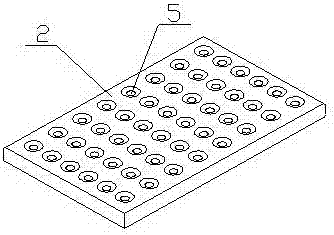

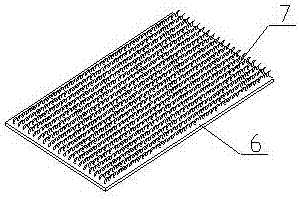

[0047] A building interior wall thermal insulation board of the present invention is realized in this way, a kind of building interior wall thermal insulation board of the present invention is made of cement fixed layer (1), coconut palm hair layer (2), steel wire mesh (3), diatomite (4) Composed of connecting holes (5), the coconut palm wool layer (2) is in the middle, and steel wire meshes (3) are respectively placed above and below the coconut palm wool layer (2), and a plurality of communicating holes (5) are evenly opened on the coconut palm wool layer ), the outer sides of the two steel wire meshes (3) are respectively poured with cement fixed layers (1), and the cement fixed layers (1) on both sides are connected through the through communication holes (5) cement pillars, and the cement fixed The outer side of the layer (1) is covered with a layer of diatomaceous earth (4), the thickness of the coconut palm hair layer (2) is one-third of the thickness of the entire insul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com