Non-shaft wave power generation device

A power generation device and wave energy technology, which is applied to ocean energy power generation, engine components, machines/engines, etc., can solve problems such as weak ability to capture wave energy, weak device anti-wave ability, difficult maintenance, etc., and achieve cost reduction Low energy consumption, improved energy conversion efficiency, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

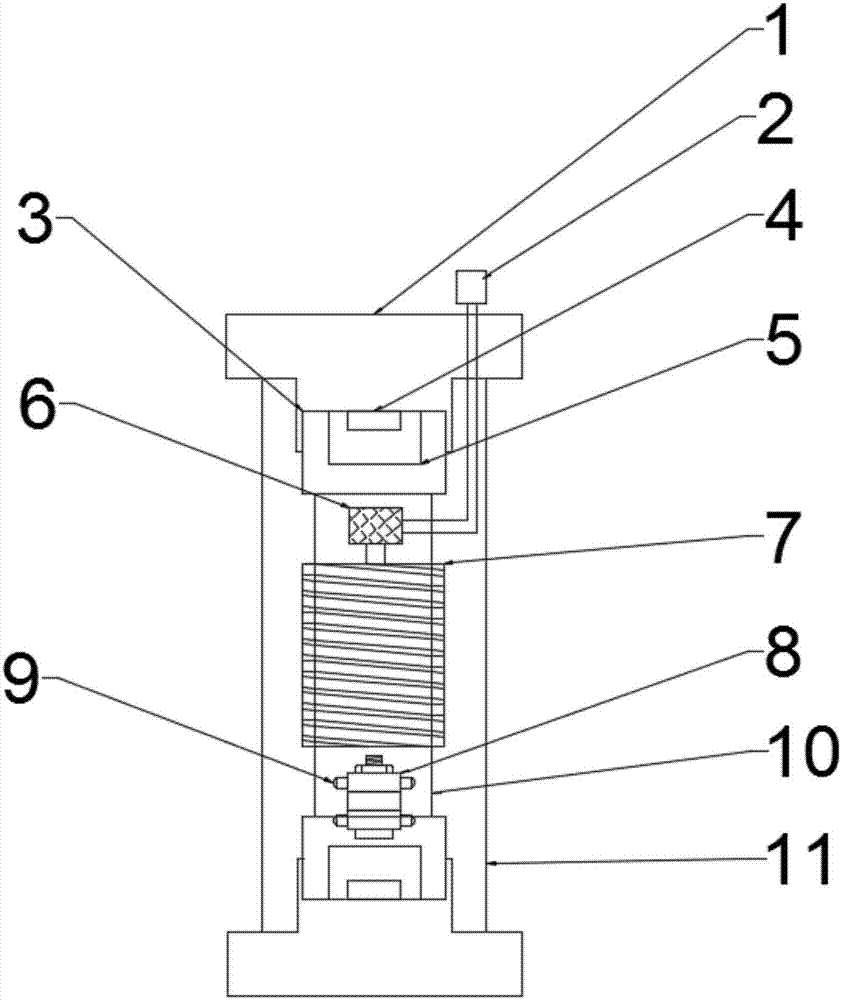

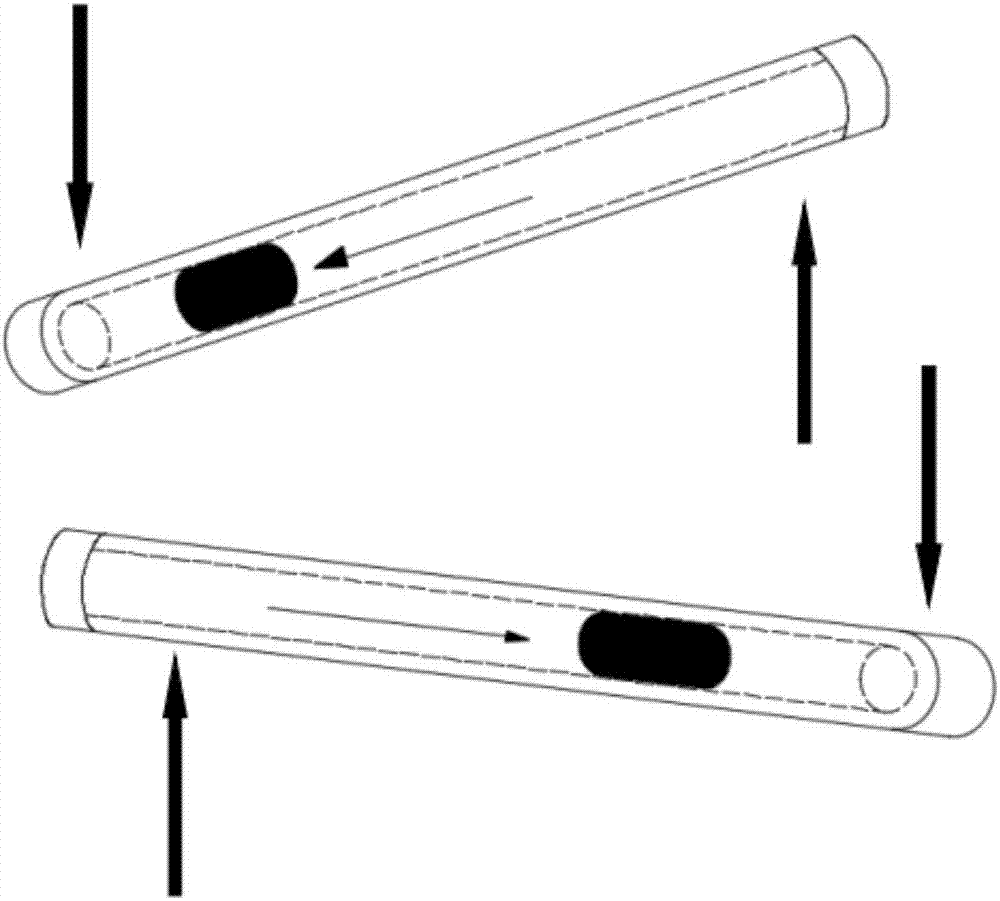

[0022] Such as figure 1 As shown, a shaftless wave energy power generation device includes an outer floating tube 11, a power generation tube 10, a magnetic group 8, a finishing circuit board 6 and an electrical device 2, and multiple sets of coils 7 are arranged outside the power generation tube 10, each The group coils 7 are all wound in multiple layers, and each layer of the coils 7 is separated by a non-metallic material, which is scotch tape or plastic film. The coil 7 includes at least one group, which can be a group of coils 7, or two groups or more than two groups, which can be set according to the size of the power generating device or the actual situation; the magnetic group 8 slides in the generator tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com