Automatic closing device and reaction device

An automatic sealing and reaction tank technology, which is applied in the direction of valve devices, engine components, functional valve types, etc., can solve the problems of inconvenient use and maintenance, narrowing the diameter of the air supply pipe, and the inability to seal tightly, so as to achieve good anti-backflow effect, Easy to manufacture and process, not easy to leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

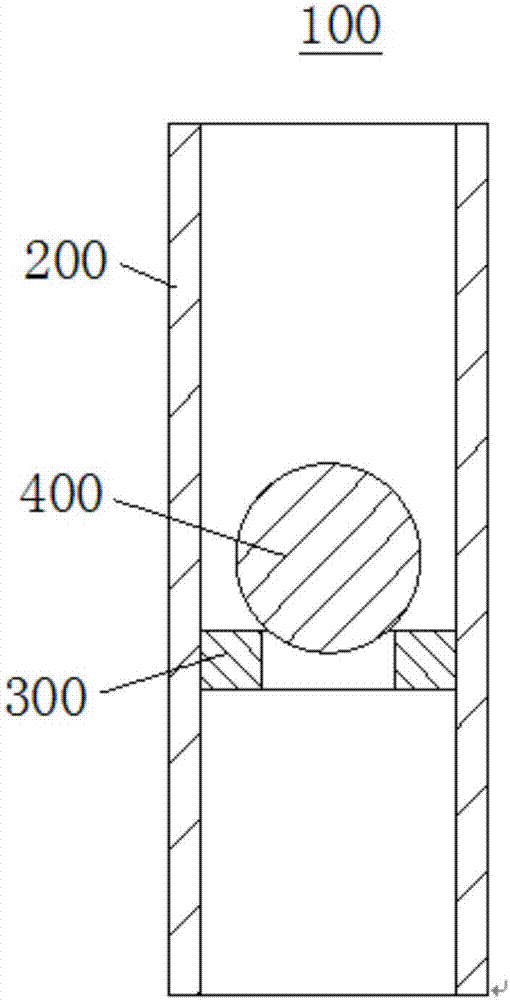

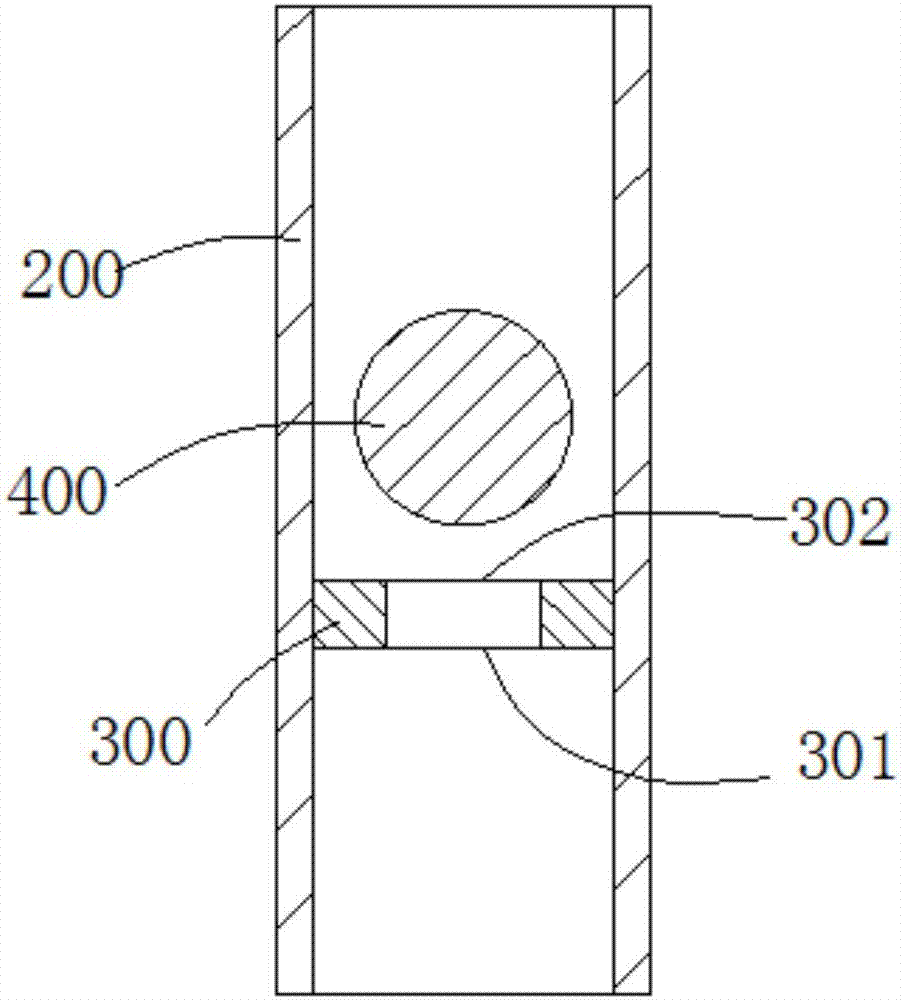

[0029] see Figure 1-2 ,in, figure 1 Shows a cross-sectional view of the air supply system in a non-working state, the non-working state refers to the state where no air is ventilated into the intake pipe 200, figure 2 It shows a cross-sectional view of the gas supply system in the working state. The working state is the state of pointing to the air in the intake pipe 200. The embodiment of the present invention provides an automatic sealing device, which is used to install in the reaction tank to prevent the reaction tank from being closed during the reaction process. The exhaust gas inside overflows from the air supply system, polluting the environment, which includes the air supply system.

[0030] The air supply system includes an air intake pipe 200 , an anti-backflow sealing ring 300 and an anti-backflow limiting member 400 .

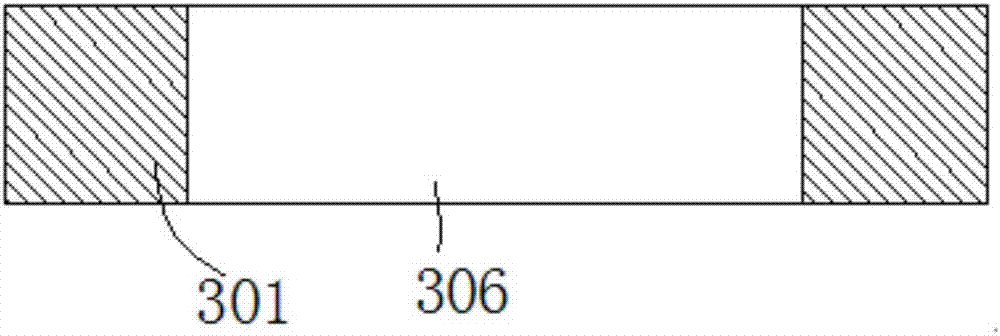

[0031] see image 3 , the anti-backflow sealing ring 300 is installed in the intake pipe 200, the anti-backflow sealing ring 300 is provided ...

Embodiment 2

[0040] see Figure 7-Figure 8 , this embodiment also provides an automatic closing device. This embodiment is a further improvement on the basis of the technical solution of Embodiment 1. The technical solution already described in Embodiment 1 is also applicable to this embodiment. In order to avoid repetition of description For cumbersomeness, the disclosed technical solution of Embodiment 1 will not be described in detail again.

[0041] Specifically, this embodiment is an improvement on the basis of Embodiment 1 that the anti-backflow limiter 400 will fall from the intake pipe 200 into the reaction tank. The air intake system 100 also includes a limiter, and the limiter is installed In the intake pipe 200, it is used to restrict the anti-backflow limiter 400 from sliding out of the intake pipe 200 in a direction away from the anti-backflow sealing ring 300. For example, when the intake system 100 is installed, the intake pipe 200 can only be vertical in one direction Sett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com