Natural cream powder and processing method thereof

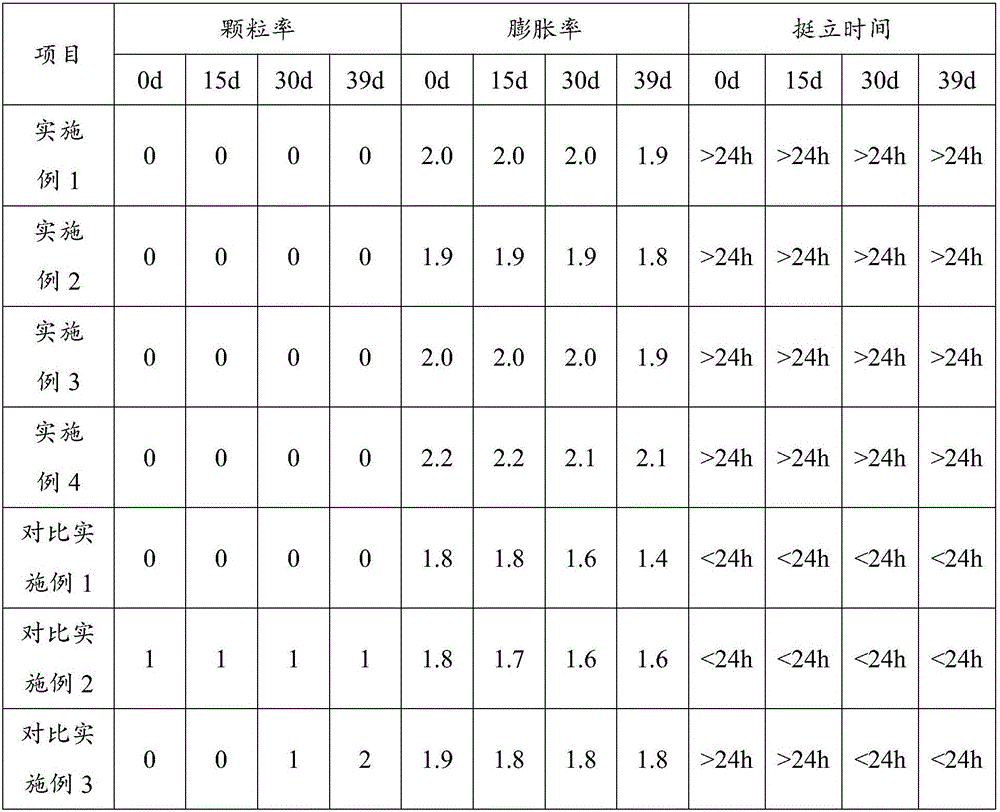

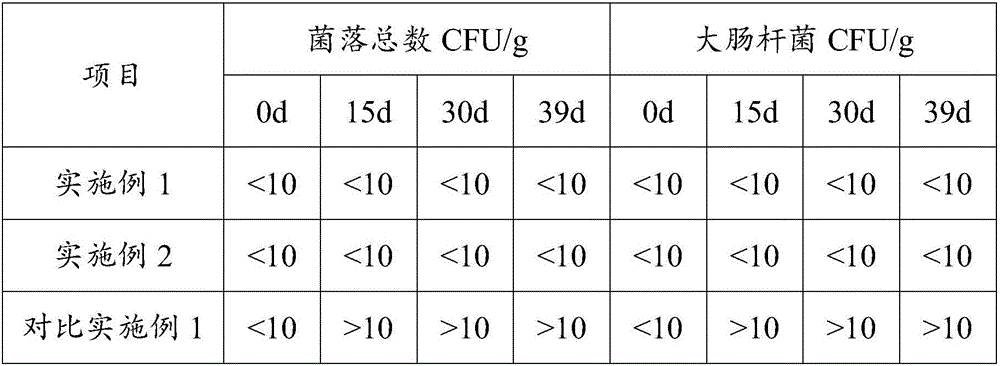

A processing method and technology of cream, which is applied in the field of dairy products, can solve the problems of poor stability of natural cream, short shelf life, high precision requirements of raw material equipment, etc., and achieve the effect of mellow and natural nutritional value, excellent quality and improved standing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A processing method of natural cream includes the following steps:

[0042] (1) Raw milk acceptance: uniform sampling during acceptance, sensory, physical and chemical, freezing point detection, acidity, alcohol, rose red, boiling, and nitrate and nitrite tests. Raw milk can only be put into storage after it has been accepted.

[0043] (2) Separation: separation temperature is 58°C. The separated cream is transported to the storage tank. The storage tank has been modified, and a pipe is added inside the cylinder. The cream material sticks to the wall from the upper part through the pipe and flows out through the lower outlet.

[0044] (3) Cooling: Cool the cream to 10°C.

[0045] (4) Sterilization: A plate type sterilizer is used to sterilize the cooled cream. The sterilization temperature is 115°C and the time is 15s.

[0046] (5) Cooling: The sterilized cream is cooled by casing cooling water, and the cooling time is 35s.

[0047] (6) Filling: The cream material after cooling ...

Embodiment 2

[0050] A processing method of natural cream includes the following steps:

[0051] (1) Raw milk acceptance: uniform sampling during acceptance, sensory, physical and chemical, freezing point detection, acidity, alcohol, rose red, boiling, and nitrate and nitrite tests. It can be put into storage only after passing the test.

[0052] (2) Separation: separation temperature is 50°C. The separated cream is transported to the storage tank. The storage tank has been modified and a pipe is added inside the cylinder. The cream material sticks to the wall from the upper part through the pipe and flows out through the lower outlet.

[0053] (3) Cooling: Cool the cream to 8°C.

[0054] (4) Sterilization: A plate type sterilizer is used to sterilize the cooled cream. The sterilization temperature is 105°C and the time is 40s.

[0055] (5) Cooling: The sterilized cream is cooled by casing cooling water, and the cooling time is 20s.

[0056] (6) Filling: The cream material after cooling enters the s...

Embodiment 3

[0059] A processing method of natural cream includes the following steps:

[0060] (1) Raw milk acceptance: uniform sampling during acceptance, sensory, physical and chemical, freezing point detection, acidity, alcohol, rose red, boiling, and nitrate and nitrite tests. It can be put into storage only after passing the test.

[0061] (2) Separation: The separation temperature is 65°C. The separated cream is transported to the storage tank. The storage tank has been modified and a pipe is added inside the cylinder. The cream material sticks to the wall from the upper part through the pipe and flows out through the lower outlet.

[0062] (3) Cooling: Cool the cream to 6°C.

[0063] (4) Sterilization: A plate type sterilizer is used to sterilize the cooled cream. The sterilization temperature is 125°C and the time is 10s.

[0064] (5) Cooling: The sterilized cream is cooled by casing cooling water, and the cooling time is 45s.

[0065] (6) Filling: The cream material after cooling enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com