Surface treatment device of tapered roller

A technology of surface treatment devices and tapered rollers, applied in the direction of filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve the problems of low cleaning efficiency and incomplete cleaning, and achieve practical equipment and mixing time And the effect of energy consumption reduction and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

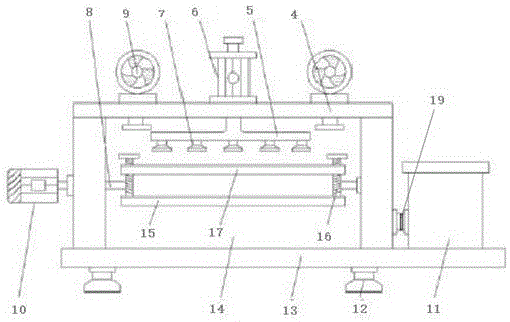

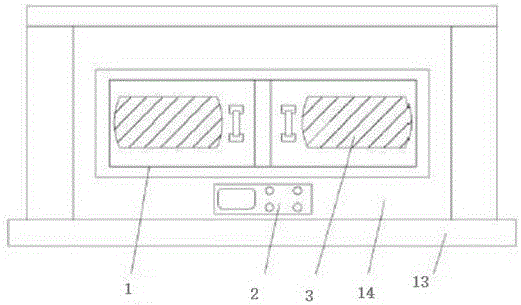

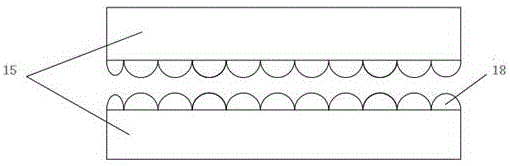

[0024] Such as Figure 1~5 As shown, a tapered roller surface treatment device includes a casing 14, a support base plate 13, and a nozzle 7. Support feet 12 are provided at both ends of the bottom of the support base plate 13, and a sewage water collection tank 11 is fixed on the support base plate 13. The sewage collecting tank 11 is connected with the casing 14 through a sewage pipe, and a filter screen 19 is arranged in the sewage pipe, and the filter screen 19 has two layers. The net 21 is equipped with a filter device to filter impurities, avoiding the situation that the impurities after cleaning are easy to cause blockage, greatly reducing energy consumption, effectively avoiding unnecessary mechanical loss, improving the use efficiency and durability of the device, and making it more practical Outstanding, save time, save cost, improve cleaning efficiency, and speed up the rate of sewage discharge. The left side of the casing 14 is provided with a motor 10, the output...

Embodiment 2

[0028] like Figure 1~5 As shown, when a tapered roller surface treatment device is working, open the cabinet door 1, place the tapered rollers between the upper clamping plate 17 and the lower clamping plate 15 in an orderly manner, and adjust the bolt column 16 to fix the tapered rollers. The PLC controller 2 controls the motor 10 to start to work, and the upper splint 17 and the lower splint 15 are driven to rotate through the rotating shaft 8. The water pump 6 rotates and sprays water from the rotating nozzle 7 through the conduit 5 to clean the tapered rollers without dead ends. The high-pressure vortex blower 9 on the top cover 14 dries and dries the cleaned tapered rollers, so that the tapered rollers can obtain a certain degree of dryness, improve the cleaning quality of the tapered rollers, and pass the cleaned sewage through the filter screen 19 Store it in the sewage water collection tank 11 to prevent impurities from clogging pipelines and polluting the environment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com