Dynamic calibration method for welding machine output display value

A dynamic correction and welding machine technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of not being able to correct the current value and voltage value at the same time, affecting production efficiency and cost, and wasting time when returning to the factory for maintenance. Achieve the effects of improving implementability, improving production efficiency and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

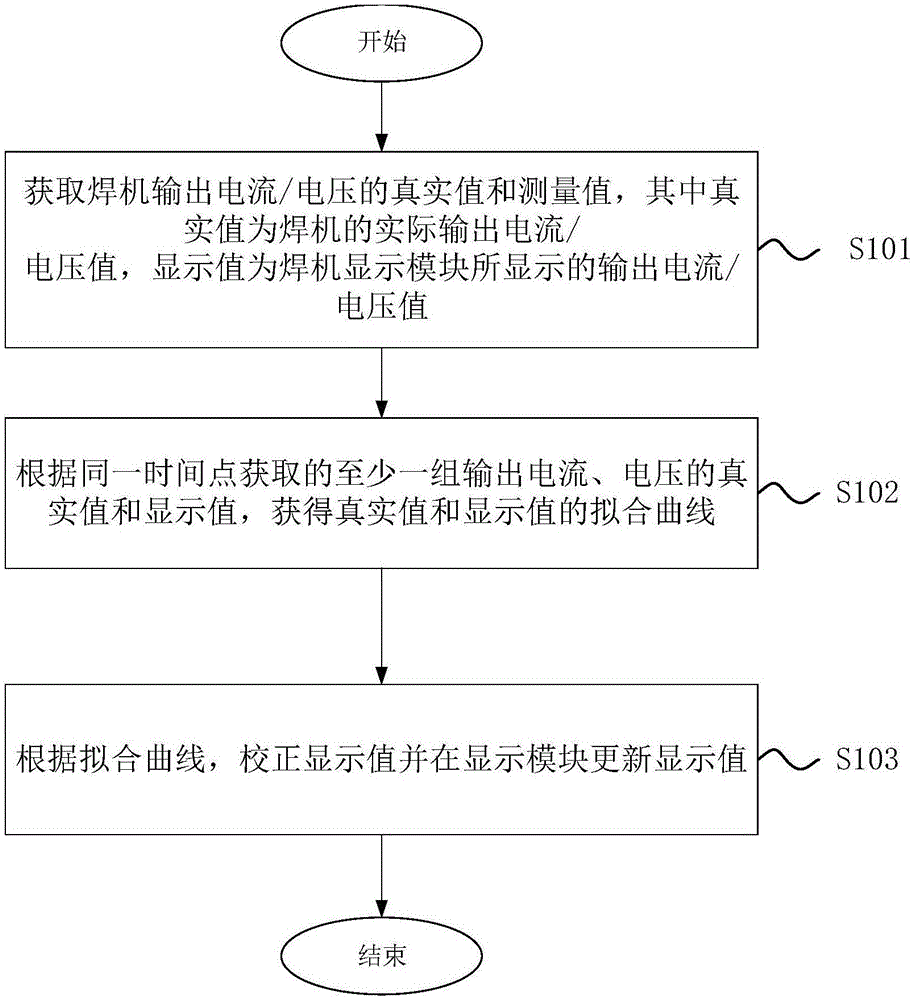

[0042] Such as figure 1 As shown, the method for dynamically correcting the output display value of the welding machine in this embodiment includes the following steps:

[0043] S101. Obtain the actual value and measured value of the output current / voltage of the welding machine, wherein the actual value is the actual output current / voltage value of the welding machine, and the displayed value is the output current / voltage value displayed by the display module of the welding machine;

[0044] Specifically, the current sensor is connected to the output circuit of the welding machine, and the voltage sensor is positively and negatively connected to the output electrode of the welding machine to accurately measure the real value of the output current / voltage of the welding machine. At the same time, read the display value of the welding machine output current and voltage displayed by the welding machine itself.

[0045] For example: use the current / voltage sensor of the external...

Embodiment 2

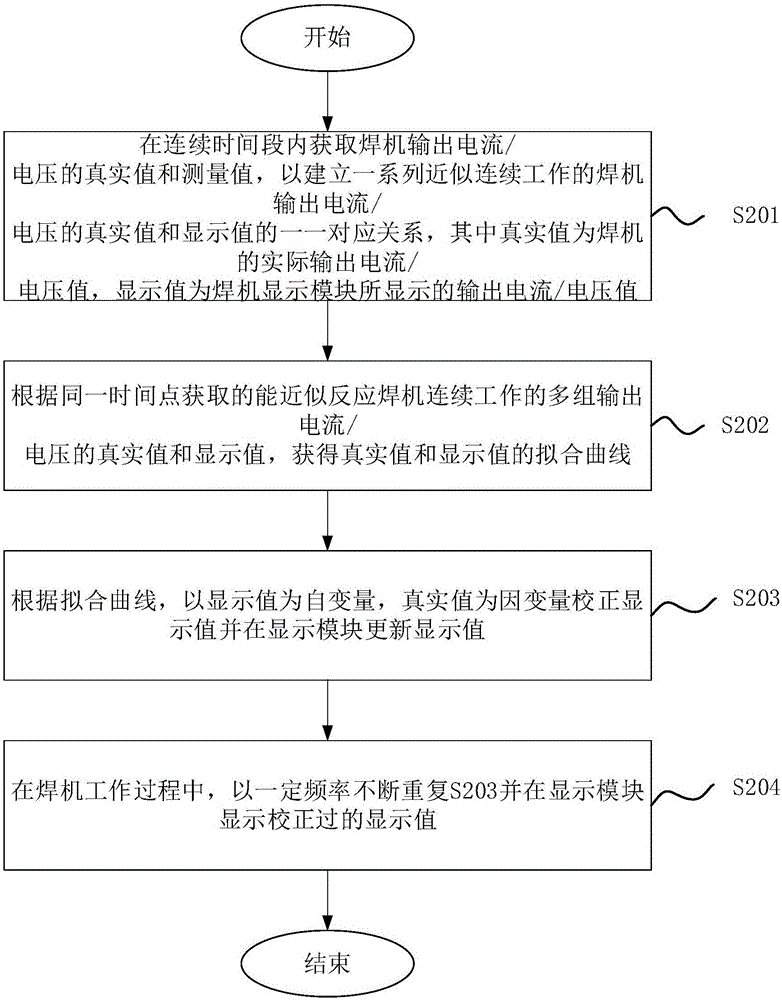

[0053] Such as figure 2 As shown, another method for correcting the output display value of the welding machine described in this embodiment includes the following steps:

[0054] S201. Obtain the actual value and measured value of the output current / voltage of the welding machine in a continuous period of time, so as to establish a one-to-one correspondence between the actual value and the displayed value of the output current / voltage of the welding machine that is approximately continuously working, wherein the actual value It is the actual output current / voltage value of the welding machine, and the displayed value is the output current / voltage value displayed by the display module of the welding machine;

[0055] Specifically, when the welding machine is in the working state, the current sensor is connected to the output circuit of the welding machine, and the voltage sensor is positively and negatively connected to the output electrode of the welding machine to accuratel...

Embodiment approach

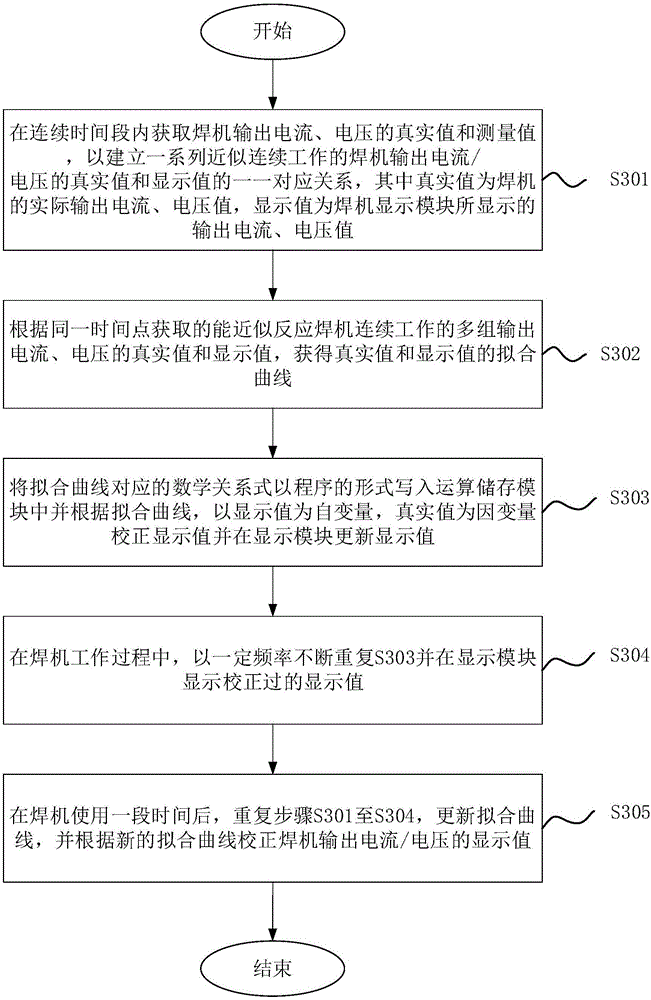

[0069] Such as image 3 As shown, this embodiment is another implementation method of the dynamic correction method for the output display value of the welding machine, including the following steps:

[0070] S301. Obtain the actual value and measured value of the output current and voltage of the welding machine in a continuous period of time, so as to establish a one-to-one correspondence between the actual value and the displayed value of the output current / voltage of the welding machine that is approximately continuously working, wherein the actual value It is the actual output current and voltage value of the welding machine, and the displayed value is the output current and voltage value displayed by the display module of the welding machine;

[0071] S302. Obtain a fitting curve of the actual value and the displayed value according to the actual values and displayed values of multiple sets of output currents and voltages obtained at the same time point that can appr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com